Fichter Maschinen GmbH designed for IFM Ecomatic in Kressbronn has a system that can carry out various joining and dosing processes. It consists of two dosing stations and a joining station. The dosing stations are each equipped with a 2K dispenser and a "Viscotreat-R" storage tank from Viscotec Pumpen- und Dosiertechnik.

Fichter Maschinen GmbH designed for IFM Ecomatic in Kressbronn has a system that can carry out various joining and dosing processes. It consists of two dosing stations and a joining station. The dosing stations are each equipped with a 2K dispenser and a "Viscotreat-R" storage tank from Viscotec Pumpen- und Dosiertechnik.

Since 1969, headquartered in Essen, Germany, IFM Electronic GmbH has been producing sensors for motion control and safety technology, position and process sensors, products for industrial image processing and communication as well as identification systems and systems for mobile work machines.

First dosing station

At the first station of the new plant, the material "Delo Duopox AD821" will be extracted via suction lances from the 20 L hobbock of the material supplier into the Viscotreat-R storage tanks. Subsequently, the 2-component material, pressure-controlled from the storage tank, is fed via a hose line to the mixing and dosing head of the dosing cell - each component separately. In the next step, the mixture and then the dosage of the material for sealing in the housing frame take place. Numerous challenges have been mastered for this process:

At the first station of the new plant, the material "Delo Duopox AD821" will be extracted via suction lances from the 20 L hobbock of the material supplier into the Viscotreat-R storage tanks. Subsequently, the 2-component material, pressure-controlled from the storage tank, is fed via a hose line to the mixing and dosing head of the dosing cell - each component separately. In the next step, the mixture and then the dosage of the material for sealing in the housing frame take place. Numerous challenges have been mastered for this process:

The system should run as long as possible, autonomously without the intervention of an operator. The handling of the delivery containers should be ergonomic through the use of suction lances. To protect the environment and employees, a closed system was required. The thread break at the end of each dosage should be clean, to avoid contamination of the component and the system

Second dosing station

In the second dosing station of the plant the thermal grease "Henkel-Bergquist Gapfiller 1500LV" is applied. The removal of the paste from the 600 ml cartridges of the material supplier takes place here via cartridge pressings. The gap filler is fed via chemical hoses to the mixing and dosing head in the dosing cell, then the dosing of the material takes place on predetermined areas on a printed circuit board. The aim of the application: to deliver the resulting temperatures to the housing. Thus, the heat balance of the control unit can be kept as low as possible. Also with this part of the plant some hurdles had to be taken:

In the second dosing station of the plant the thermal grease "Henkel-Bergquist Gapfiller 1500LV" is applied. The removal of the paste from the 600 ml cartridges of the material supplier takes place here via cartridge pressings. The gap filler is fed via chemical hoses to the mixing and dosing head in the dosing cell, then the dosing of the material takes place on predetermined areas on a printed circuit board. The aim of the application: to deliver the resulting temperatures to the housing. Thus, the heat balance of the control unit can be kept as low as possible. Also with this part of the plant some hurdles had to be taken:

It was to ensure a sufficient supply of material to the mixing and dosing while dosing the defined amount, in the available dosing. In addition, the dosage of the highly abrasive thermal paste with a long service life of the dosing equipment had to be ensured by the use of special materials in the area of the mixing and dosing head.

The process reliability achieved was achieved, among other things, by the know-how about the materials to be processed by the dosing specialist. They selected component materials specially tailored to the medium to be dosed in the product-contacting area. This particularly affected the dispensers and removal pumps.

3D Camera | Industrial image processing

3D Camera | Industrial image processing

Very gentle on materials The processing of the media was very gentle on the material, thanks in particular to the low-shear mode of operation of the dispensers during removal and dosing. The system now promises absolute process reliability. Production at IFM Ecomatic succeeds without rejects.

You might also be interested in...

Gateways | The bridge to the Industry 4.0 factory

Level sensor | Level switch for simple to IIoT use

IFM Electronic | Technology for everyone

Parameterization software for IO-Link sensors for the Moneo platform

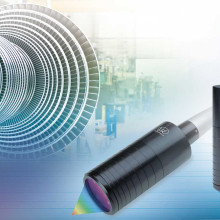

Distance sensors | Distance, path, distance & Co.