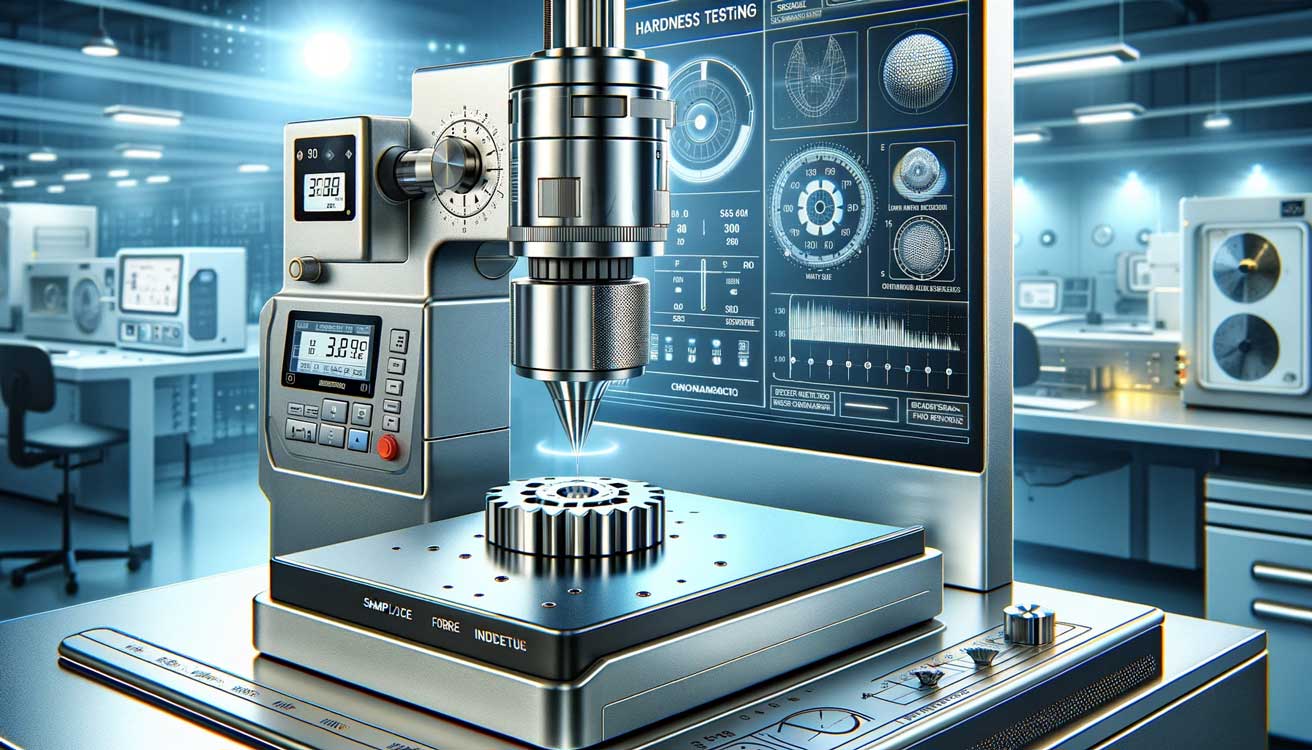

Especially when it comes to metals, this is the most common Hardness Testing for use if the material should be checked mechanically. In our current article we present the latest advances in the field Vickers, Knoop- And Brinell-Hardness test procedure. We also answer your questions about this area of materials science.

Contents

The endurance test – the most important things in brief

The hardness test, a crucial procedure in the material Science and quality assurance. Modern methods such as the Vickers and Rockwell methods offer more precise measurements and are increasingly automated to increase efficiency and accuracy.

The hardness test, a crucial procedure in the material Science and quality assurance. Modern methods such as the Vickers and Rockwell methods offer more precise measurements and are increasingly automated to increase efficiency and accuracy.

A current trend in hardness testing is integration digital technologies, which enable more detailed data analysis and better reproducibility of results. Portable hardness testing devices are also becoming increasingly popular because they offer flexible application options directly at the testing site.

The development towards microscopic and nanoscopic hardness testing opens up new possibilities in the Research and developmentg of high-performance materials, demonstrating that hardness testing remains a central component in advancing materials research and development.

VDI guidelines for hardness testing

November 14.11.2023, XNUMX | The policy VDI/VDE 2616 sheet 1 “Hardness testing on metallic materials” provides an overview of the common hardness testing procedures for metallic materials. The guideline describes the individual procedures and their practical application as well as the respective special features with the individual advantages and disadvantages.

Pressure sensors | Pressure measurement technology goes digital

Pressure sensors | Pressure measurement technology goes digital

Clear diagrams and tables make it easier to select a suitable procedure. VDI/VDE 2616 Sheet 1 supplements the existing standards for the hardness testing of metals. In addition, non-standardized test procedures are taken into account, which are included in the Testing practice are widespread.

The guideline VDI/VDE 2616 Sheet 1 “Hardness testing of metallic materials” was published in September 2023 and is available at Beuth Verlag .

Hardness testing on crankshafts

October 29.10.2021, XNUMX | Crankshafts must meet high requirements in terms of strength, pressure or impact loads because they have to withstand complex mechanical stresses. In addition to the chemical composition of the materials, the surface treatment plays a crucial role. With the Induction hardening Crankshafts can also be hardened specifically in the highly stressed radius areas.

October 29.10.2021, XNUMX | Crankshafts must meet high requirements in terms of strength, pressure or impact loads because they have to withstand complex mechanical stresses. In addition to the chemical composition of the materials, the surface treatment plays a crucial role. With the Induction hardening Crankshafts can also be hardened specifically in the highly stressed radius areas.

To measure the quality of the surface treatment, a large crankshaft manufacturer uses hardness testing systems specially developed for this application Hegewald & Peschke a. The testing system can be used to test crankshafts over their entire alignment circle or diameter. The hardness measurement using the Rockwell C method is carried out perpendicular to the axis of rotation of the crankshaft.

Due to the crankshaft size, the hardness test head is positioned according to the test requirement. The crankshaft is installed via the Pneumatics tense. This increases the Reproducibility clear from the measurement. Depending on the scope of the test, up to 30 crankshafts can be tested per hour.

Knoop, Vickers, Brinell hardness testing methods

April 24.04.2018, XNUMX | Under the brand name Wilson offers Buehler a new generation of Rockwell, Knoop, Vickers, Brinell and universal hardness testers. The company presents the new models VH3100, VH3300, VH1202 and VH1150. The “Diamet” hardness testing software and a large number of certified hardness comparison plates were also newly developed.

April 24.04.2018, XNUMX | Under the brand name Wilson offers Buehler a new generation of Rockwell, Knoop, Vickers, Brinell and universal hardness testers. The company presents the new models VH3100, VH3300, VH1202 and VH1150. The “Diamet” hardness testing software and a large number of certified hardness comparison plates were also newly developed.

In particular, the automated hardness testing systems VH3300 and the hardness testing systems from the VH3100 series offer a fully integrated platform that meets all requirements Vickers and Knoop-hardness test. The Wilson hardness testing systems VH1102 and VH1202 are a flexible, cost-effective and reliable solution for Knoop and Vickers microhardness testing.

Thanks to different versions of one StandaloneFrom versions for testing laboratories with relatively low sample volumes to a fully equipped system that is particularly suitable for industrial use and applications with high sample throughput, these micro hardness testers can be adapted to a variety of requirements.

The Diamet software for automated hardness testing enables optimal evaluation of macro-Vickers, micro-Vickers, Knoop, Rockwell and Brinell hardness tests. Analogue, digital and automated solutions are offered. The software features include very good load control and monitoring with automatic lighting, automatic focus, and automatic measurement as well as state-of-the-art functions for a variety of quality control applications.

Frequently asked questions and basics

How does the hardness test work?

The hardness test is a method of determining the resistance of a material to permanent deformation, penetration, or scratches. There are different methods of hardness testing. The aim of all of these methods is to see how much resistance the material offers to the penetration of a harder test specimen. The results provide information about material properties such as wear resistance and ductility of the material.

What hardness testing methods are there?

There are different methods of hardness testing, the most common are:

Brinell hardness test

In the Brinell method, hardness is determined using a hard steel or carbide ball that is pressed onto the material with a defined test force for a specific time. Hardness is determined by measuring the diameter of the indentation.

Hardness test according to Vickers

Similar to Brinell, but the Vickers hardness test uses a diamond pyramid with a square base. Hardness is determined by the ratio of the applied load to the surface area of the indentation size.

Rockwell hardness test

This method uses either a steel ball or a diamond cone as the indenter. Hardness is determined by the depth of indentation under a large load compared to the depth of penetration under a smaller preload.

Shore hardness (Durometer)

Used primarily for elastomers and polymers, it measures the penetration depth of a specific indenter.

Knoop hardness

Similar to Vickers but with an elongated diamond, suitable for thin layers or brittle materials.

Mohs hardness

A qualitative scale of mineral scratch resistance, with softer materials being scratched by harder ones.

Why is hardness tested?

The results of a hardness test provide information about properties such as wear resistance and Ductility of the material and are important for quality control and material selection in various industrial sectors.

How is the Vickers hardness test carried out?

In the Vickers hardness test, the hardness of a material is determined by measuring the length of the diagonal of a square indentation formed by a Diamond pyramid is left under a defined load. The diagonal of the indentation provides information about the hardness of the material, as harder materials produce smaller indentations with shorter diagonals.

Source: This article is based on information from the following companies: Buehler, Hegewald & Peschke, VDI.

You might also be interested in...

Universally applicable intelligent CAQ system

Measure solar radiation and determine UV Eruthem radiation

Learn everything about infrared camera measurement technology at Optris

Large wind turbine successfully tested on a system test bench

CAQ Software | Intelligent measurement and testing technology