Devices like data logger and Data splitter play a central role in modern data collection, processing and analysis. Learn from new innovations how these technologies increase efficiency in the Data acquisition increase, improve the accuracy of data analysis and thus make a decisive contribution to optimizing industrial processes.

Contents

- Codesys Automation Server for intuitive data acquisition

- Smart data logger with 4 inputs and 40 measuring channels

- IO-Link data splitter for digital Industry 4.0 retrofit

- Transparent measurement data acquisition across the entire measurement chain

- FAQ

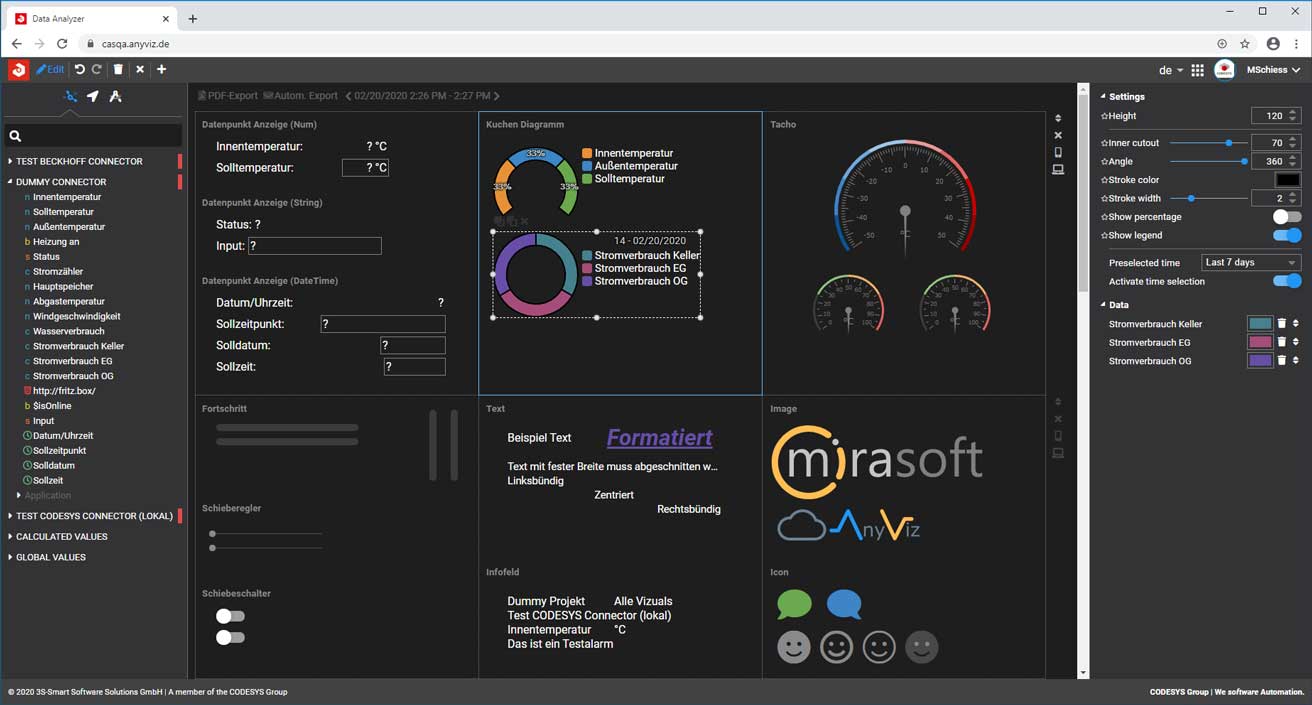

Codesys Automation Server for intuitive data acquisition

October 20.10.2020, 100.000 | There are currently more than XNUMX users worldwide for the Codesys Automation Server. The Industry 4.0 platform supports the management of PLC controls and the associated applications as well as the roll-out of updates. The Codesys platform offers a secure infrastructure for remote access, debugging or web visualization.

Codesys has added an important application to its automation server: With so-called Data Analyzer projects users can monitor, operate and analyze their machine and plant controls remotely. Cloud technology makes this possible from anywhere in the world.

Codesys data acquisition focuses on core tasks

With previous approaches, the focus is usually on the transmission path, keywords MQTT or OPC UA. The new feature set, on the other hand, focuses on the Core tasks. This means comfortable processing, display, analysis and modification of data. Users automatically use the secure one Communication of IEC 61131-3 Codesys Automation Servers as a manufacturer-independent platform.

By integrating the automation cloud from Mirasoft Anyviz The package was implemented in the Codesys Automation Server. Matthew Kolmer, Managing Director of Mirasoft: “Although automation companies need diverse solutions, they want to use one and the same product for them. The integration of Anyviz in the Codesys Automation Server results in a complete solution, the approaches of which are perfectly intertwined. "

The new function package with integrated data analysis can be used immediately. The Codesys automation server is up or free until the end of 2020 to disposal. Registration is possible in the Codesys Store.

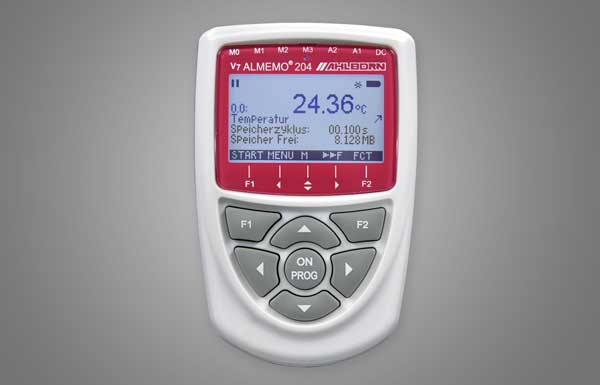

Smart data logger with 4 inputs and 40 measuring channels

May 15.05.2020, 204 | The new data logger Almemo XNUMX from Ahlborn is suitable for numerous measurement tasks. It has four measuring inputs for digital sensors that can be expanded to up to 40 measuring channels. There are multifunctional sensors for this, e.g. B. measuring the relative humidity while simultaneously measuring air pressure and Temperature. Unused channels can be expanded as functional channels, so that in the example mentioned, the absolute humidity is also recorded as a display value.

May 15.05.2020, 204 | The new data logger Almemo XNUMX from Ahlborn is suitable for numerous measurement tasks. It has four measuring inputs for digital sensors that can be expanded to up to 40 measuring channels. There are multifunctional sensors for this, e.g. B. measuring the relative humidity while simultaneously measuring air pressure and Temperature. Unused channels can be expanded as functional channels, so that in the example mentioned, the absolute humidity is also recorded as a display value.

Multifunctional measurement data acquisition system

With the intelligent Almemo D7 connectors, the data logger becomes multifunctional. The D7 connector plug for any digital Sensors works with a fully digital interface to the measuring device and offers up to ten function channels. The Plug have their own processor. The sensors work in parallel with their sensor-specific measuring rate.

They achieve a high speed for the query dynamic measurements. The digital interface offers high transmission security to the device. Individual sensor parameters are also saved in the connector. Freely selectable comments can also be stored.

IO-Link data splitter for digital Industry 4.0 retrofit

March 20.03.2020, XNUMX | Today, sensors often collect large amounts of data from the Control Technology is not processed at all in many applications. With the new IO-Link data splitter E43406 from IFM Electronic Valuable information can be generated from this data. The data splitter allows existing systems and machines to be retrofitted in terms of Industry 4.0.

March 20.03.2020, XNUMX | Today, sensors often collect large amounts of data from the Control Technology is not processed at all in many applications. With the new IO-Link data splitter E43406 from IFM Electronic Valuable information can be generated from this data. The data splitter allows existing systems and machines to be retrofitted in terms of Industry 4.0.

An typical example for unused data are pressure sensors on machines with a compressed air connection. They are only configured as a simple limit switch to ensure trouble-free operation of the machine. From the continuous monitoring of the Air pressureCompressed air leaks, for example, can be quickly identified and remedied. Compressed air consumption decreases. This leads to higher energy efficiency.

However, changes to the existing PLC are complex and expensive. In addition, the machine manufacturer's warranty may expire. The new data splitters E43406 and E43410 from IFM offer a solution here. The data splitter is simply between IO-Link capable sensor and PLC and connected to any IO-Link master.

Control remains as it is

From the point of view of control technology, nothing changes. The switching signals or analog values of the sensor are transferred to the PLC as before. It is not necessary to adapt the control in terms of hardware and software. The data splitter transfers the measured values from the sensor in parallel to the connected one IO-Link master.

This makes it easy to evaluate the measured values in higher-level systems. The IO-Link masters from IFM are equipped with a JSON interface, which allows, for example, easy connection to a database.

IFM's data splitters are working manufacturer independent and can be used with any IO-Link sensors and IO-Link master modules. The sensor can also be parameterized via the data splitter. However, when delivered, this option is blocked for security reasons. It must first be enabled in the parameterization of the data splitter.

Transparent measurement data acquisition across the entire measurement chain

28.06.2018 | Kistler presents the “Kidaq” data acquisition system, which for the first time offers all components of a measurement task from a single source. The globally unique transparency of the entire measurement chain ensures the highest level of measurement reliability.

28.06.2018 | Kistler presents the “Kidaq” data acquisition system, which for the first time offers all components of a measurement task from a single source. The globally unique transparency of the entire measurement chain ensures the highest level of measurement reliability.

“Kidaq is an important step for us towards Industry 4.0 or Internet of Things. With the new data acquisition system, we now have all components of the measurement chain in our portfolio - and are moving from a component manufacturer to a solution provider," explains Marc Schaad, Head of Division ST at Kistler.

The patent pendingThe system has a modular structure and can be flexibly expanded at any time with additional measuring modules and units. Thanks to various housing shapes and numerous modules, it can be used in almost any application. Depending on the area of application, different versions are available for laboratory applications, fixed installations and mobile use. The user chooses from the hardware, Software and the sensors simply select the components that he needs for his measuring task - and thus receives the optimal data acquisition system for his specific application.

A key advantage of Kidaq is that Transparency and the know-how across the entire measurement chain. Because the measurement technology experts qualify the components of the measurement chain and for the customer application calibrate, they know their properties exactly and can thus make reliable statements about measurement reliability.

Another important component of Lidaq is the web-based software "Kistudio Lab", with which measurement tasks and projects can be easily edited and managed.

FAQ

What is Codesys?

Codesys (Cocontroller Dedevelopment System) is an integrated development environment for the PLC (programmable logic controller). The software for PLC programming was developed by the Codesys Group according to the IEC 61131-3 standard for the development of applications in industrial automation.

Source: This article is based on information from the following companies: Ahlborn, IFM Electronic, Kistler, Mirasoft.

You might also be interested in...

Gateways | The bridge to the Industry 4.0 factory

Level sensor | Level switch for simple to IIoT use

IFM Electronic | Technology for everyone

Torque measuring shaft | Innovations and functional principle

Measure solar radiation and determine UV Eruthem radiation