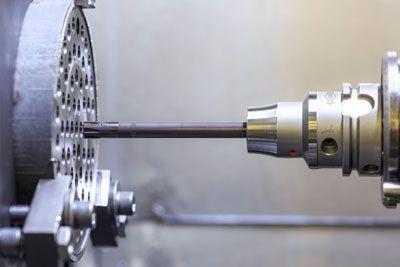

Multi-bladed reamers are the tool of choice when high cutting rates and short machining times are required. Due to the limitations of conventional manufacturing processes, it has not been possible with steel base bodies to distribute the coolant specifically to all effective points of the tool. Thanks to additive manufacturing, Mapal has succeeded in reshaping the coolant supply and the coolant outlet shape and optimally adjusting it to friction machining.

Multi-bladed reamers are the tool of choice when high cutting rates and short machining times are required. Due to the limitations of conventional manufacturing processes, it has not been possible with steel base bodies to distribute the coolant specifically to all effective points of the tool. Thanks to additive manufacturing, Mapal has succeeded in reshaping the coolant supply and the coolant outlet shape and optimally adjusting it to friction machining.

In the constructive design of the cooling channel holes had previously been compromised. Thanks to special KSS outlets on the multi-bladed reamers, the coolant now reaches exactly where it is needed. This ensures optimum chip removal and ideal cooling as well as efficient lubrication of the cutting edge and the round grinding bevel. This in turn leads to less abrasive wear of the Rundschlifffase, better chip removal and optimized machining results.

Cryogenic cooling reduces wear and tear and tool life

Cryogenic cooling reduces wear and tear and tool life

All reamers of the three "Monoream" series are presented with the new additively manufactured tool heads and thus with optimized cooling and lubrication - even when using minimum quantity lubrication. The reamers are available as fixed (600), stretchable (700) and adjustable (800) variants. The three series are interchangeable with each other. As a straight or left bevel and in short and long versions, they are suitable for through holes or blind holes and can be made with the appropriate cutting materials, coatings and gates depending on the material to be machined.