The Engineered Materials Group of the Parker Hannifin Corporation presents with "Roll2Seal" a completely new sealing solution for the simple and safe sealing of bores in pressureless applications. The design, for which a patent has been applied, enables simple and error-free assembly, in which the seal rolls into the seal seat without damage and without an insertion bevel.

The Engineered Materials Group of the Parker Hannifin Corporation presents with "Roll2Seal" a completely new sealing solution for the simple and safe sealing of bores in pressureless applications. The design, for which a patent has been applied, enables simple and error-free assembly, in which the seal rolls into the seal seat without damage and without an insertion bevel.

If components have already been provided with holes for subsequent assembly of other assemblies, however, these are permanently or temporarily - z. For example, during transport - to be safely closed, the designer is often faced with a problem: The hole should be closed with a lid, but the surrounding space is not sufficient for a classic flange gasket. If an insertion bevel is missing from 15 to 20 °, a radial seal is doomed to failure, as the seal would not survive the assembly attempt, even with a chamfered or rounded bore edge. Part of the seal would be sheared off.

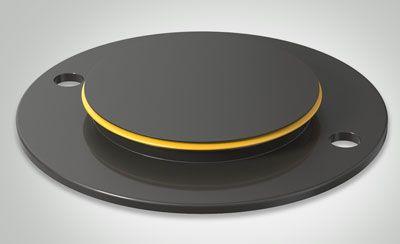

Parker Prädifa has cleverly solved this problem using the "roll instead of chute" principle: thanks to its geometry, the static Roll2Seal seal does not require a chamfer, no deburring, is self-locking and offers both temporary and permanent protection against dirt and moisture.

Both the one-time and the repeated installation and removal of the Roll2Seal are extremely easy and thanks to immunity of the seal against unbroken edges damage-free to accomplish: Instead of damaging the seal on the edge destroying, you can simply roll undamaged over the critical point. This is made possible by the innovative triangular geometry in conjunction with the special contour of the seal seat on the lid, which due to the reversing Einpresskraftverlaufs towards the end of the assembly process to an audible stop

is pulled into the hole. With the help of finite element simulation, the geometry can be adapted to the respective bore diameter.

The space- and cost-saving seal is made of suitable materials according to the thermal and mechanical requirements. The sealing system, consisting of plastic or metal lid and seal, is available on request pre-assembled.