The safe field box from Schmersal is suitable for up to eight plug-and-play installations of switching devices for machine safety. These can be control panels, sensors, tumblers, Light grids and light curtains, which themselves may come from third-party suppliers. We present the new products to you here as if they were new fieldbus integrations or the simplified one Safety field box, the significant wiringeffort saves.

Contents

- SD gateway variant with improved error diagnosis

- Safety Fieldbox for additional fieldbus systems

- Installation effort reduced for the first time

- Predictive maintenance in packaging technology

- Safety Fieldbox for variety in safety solutions

- Five installation solutions for optimum machine safety

- Safe field box with Profinet / Profisafe fieldbus interface

SD gateway variant with improved error diagnosis

Sep 19.09.2023, XNUMX | The Schmersal Group presents its new SD gateway variant. This offers improved error diagnosis, which means Minimize downtimes as well as simplify commissioning and maintenance. The user-friendly device is easy to install. Electronic safety sensors and interlocks With SD interface, comprehensive status and diagnostic data can be transferred to a higher-level machine control.

Sep 19.09.2023, XNUMX | The Schmersal Group presents its new SD gateway variant. This offers improved error diagnosis, which means Minimize downtimes as well as simplify commissioning and maintenance. The user-friendly device is easy to install. Electronic safety sensors and interlocks With SD interface, comprehensive status and diagnostic data can be transferred to a higher-level machine control.

The data of the switching devices connected in series are transmitted via the SD bus to the SDG Fieldbus gateway and sent from there via the fieldbus to the machine control. Error messages such as overtemperature, incorrect or defective actuator or an invalid combination are forwarded.

The diagnostic data is transmitted separately from the safety signals. Warning messages allow the process to be shut down in a controlled manner and maintenance can be carried out specifically without interrupting the process. A web server and the Micro SD memory card offer the following :

- Live evaluation of event logs

- Display of diagnostic data in plain text in the browser

- Direct control of the tumblers and control panels

- Event log export for evaluation and long-term storage

- Configuration of the series connection on the Micro SD card

The functionalities of the SDG Fieldbus Gateway are to be expanded in the near future. The data from the safety switching devices can then be viewed alongside Ethercat can also be transmitted via the common fieldbus protocols Profinet, Ethernet/IP and Modbus. The networking options should also be available via the connection to the Communication systems IO-Link and OPC UA be extended.

The series connection of up to 31 sensors and tumblers with the SD bus results in very slim wiring. This saves costs without sacrificing performance level (series connection for applications up to PL e). Setting up and commissioning an SD installation is convenient: all devices are automatically addressed by the gateway.

Safety Fieldbox for additional fieldbus systems

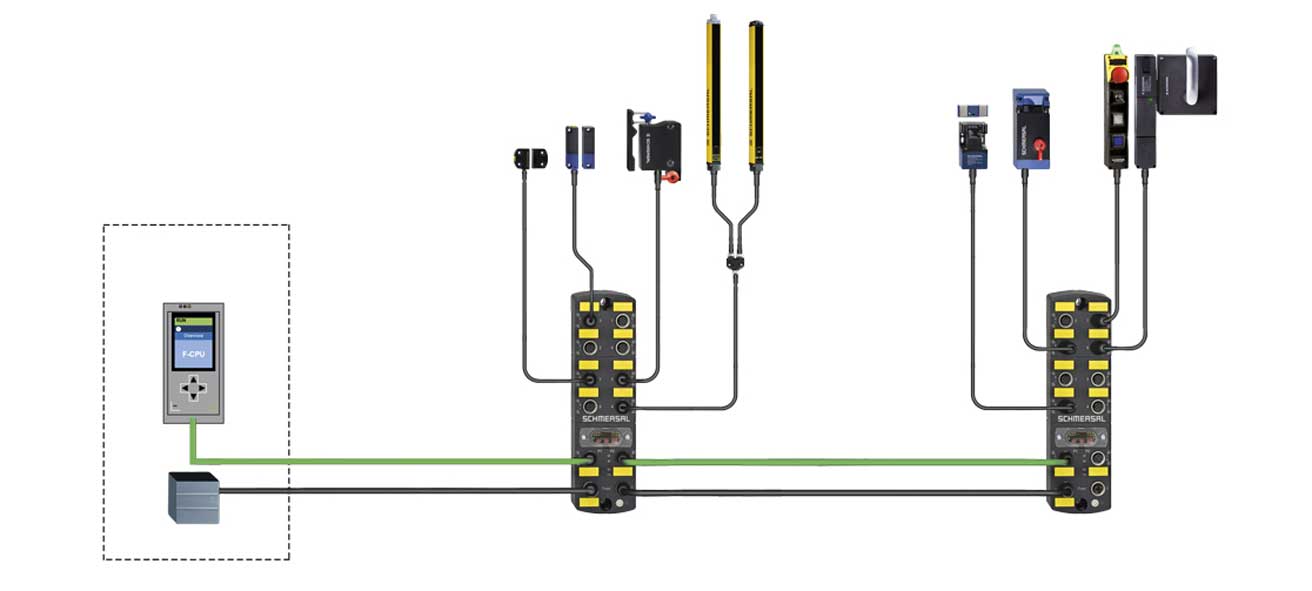

24.08.2023/XNUMX/XNUMX | Schmersal presents two new versions of its Safety Fieldbox. In addition to Profinet/Profisafe, they are now also for the bus systems Ethernet / IP with C.I.P. Safety and Ethercat available with FSoE. The designer can now use the safety functions of his machine independently of the fieldbus project, because the three versions cover the most common international control systems.

24.08.2023/XNUMX/XNUMX | Schmersal presents two new versions of its Safety Fieldbox. In addition to Profinet/Profisafe, they are now also for the bus systems Ethernet / IP with C.I.P. Safety and Ethercat available with FSoE. The designer can now use the safety functions of his machine independently of the fieldbus project, because the three versions cover the most common international control systems.

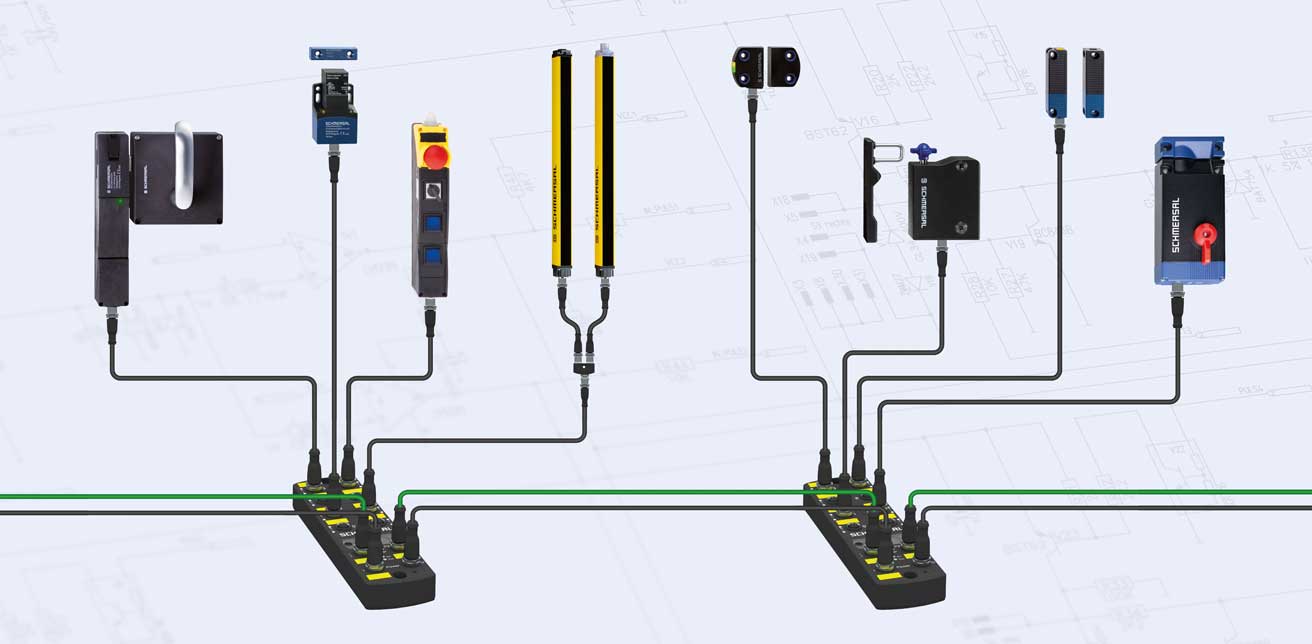

With the Safety Fieldbox, flexible safety solutions can be implemented, as well as fail-safe and quick installation and high process transparency. Up to eight safety switching devices can be easily connected via plug-and-play. Via the universal interfaces for 8 pin Many different safety switching devices such as sensors, electronic and electromechanical safety interlocks, control panels, light curtains or switches can be connected to M12 connectors.

The special an der Safety Fieldbox is that safety locking devices and Safety Light Curtain only need one M12 slot. In addition, control panels with an EMERGENCY STOP function and up to three non-safe command and signaling devices can be connected.

An integrated digital input at each device slot allows the diagnostic signals of all connected safety switching devices to be evaluated. The safety-related and operational signals required for diagnosis are collected and transmitted. The user can then use the information, for example, to detect irregularities such as a misalignment of the protective door, thus enabling early intervention in the event of service. This significantly increases the availability and wiring of safety switching devices.

Installation effort reduced for the first time

Sep 20.09.2022, 2022 | Schmersal is presenting a revised device version of its Safety Fieldbox for the first time at SPS XNUMX. A wide variety of safety switching devices can be connected decentrally in the field and freely linked using the safe field box. These can be safety locking devices, safety sensors or safety light grids. The fact that up to four control panels with emergency stop buttons and up to three non-safe command and signaling devices can be connected is currently unique on the market. This simplifies wiring for the user. The installation effort is reduced and extensive diagnostic functions become possible.

Schmersal is exhibiting at the SPS 2022.

Predictive maintenance in packaging technology

16.03.2020/XNUMX/XNUMX | the Packaging Industry with their sometimes complex processing and production systems, places high demands on the Safety Technology, because it must be flexible, efficient and available and contribute to the connectivity of the systems. Schmersal presents a safe field box with Profinet, Profisafe fieldbus interface with new safety-related solutions for the packaging industry.

16.03.2020/XNUMX/XNUMX | the Packaging Industry with their sometimes complex processing and production systems, places high demands on the Safety Technology, because it must be flexible, efficient and available and contribute to the connectivity of the systems. Schmersal presents a safe field box with Profinet, Profisafe fieldbus interface with new safety-related solutions for the packaging industry.

This is a simple and cost-effective installation solution for larger machines and plants. It enables the transmission of Diagnostic and status information.

About the universal device interfaces for 8-pin M12 connector various safety switching devices such as electronic and electromechanical safety interlocks, Sensors, connect control panels, light curtains or switches. Numerous combinations are therefore possible and the Safety Fieldbox covers typical safety concepts that are usually used on multi-part, modular packaging systems.

Multifunctional switchgear series for the bulk goods industry

Multifunctional switchgear series for the bulk goods industry

For example, two or three safety switching devices or interlocks for monitoring the position of a protective door or a maintenance flap, a safety light curtain for protecting an area of a slot and a control panel with an emergency stop button can be connected to the higher-level system via the Safety Fieldbox Safety control be connected. By using the M12 power connector to supply the Safety Fieldbox from Schmersal, up to ten Safety Fieldboxes with 80 devices can be easily connected in series, depending on the switchgear type and power consumption.

Diagnostic signals from all connected safety switching devices can be evaluated via an integrated digital input on each 8-pin device slot of the Safety Fieldbox. This leads to a higher process transparency and the trouble-free operation of the machines. Operating data can be collected, transmitted and evaluated. This information can be used to uncover irregularities and, in the event of a fault, to intervene at an early stage. The Safety Fieldbox thus becomes an important component of systems for condition monitoring and Predictive Maintenance.

Safety Fieldbox for variety in safety solutions

05.08.2019 | Flexibility and simple, fail-safe installation are key requirements for manufacturers and users of machines and automation systems when it comes to the Integration of switching devices into the control infrastructure. For this reason, bus systems and field boxes have become widespread. They enable individual switching devices to be installed or replaced within seconds and, in combination with the fieldbus system, ensure that the cabling in the system is "tidy".

05.08.2019 | Flexibility and simple, fail-safe installation are key requirements for manufacturers and users of machines and automation systems when it comes to the Integration of switching devices into the control infrastructure. For this reason, bus systems and field boxes have become widespread. They enable individual switching devices to be installed or replaced within seconds and, in combination with the fieldbus system, ensure that the cabling in the system is "tidy".

In addition, this type of Communication between switching devices, sensors and controls improved transparency, because a multitude of operating data can be collected, transmitted and evaluated. This information can be B. to uncover irregularities and thus intervene early in the event of a service.

In the safety-related circuits, this development took place with a time lag. A good three years ago the first safety field boxes for the universally used Ethernet-based fieldbuses with their respective safety protocols such as Profinet / Profisafe. They offer the same advantages as the field boxes for operational signals and even more: B. Data about the frequency of opening safety doors or the actuation of emergency stop signals that can be used for the (self-) optimization of machines and their operation - be it that the operators are trained or causes of frequent machine malfunctions be resolved.

Universal application possibilities

The fact that the Safety Field Boxes, despite these advantages, have prevailed to a lesser extent than the non-safety-oriented field boxes, may also have been due to the fact that the solutions offered were not suitable for all types of safety relays.

The aim of the new development was therefore to universal field box for the widest possible range of types and technologies of safety switching devices. The box with the designation SFB-PN is integrated into Profinet/Profisafe systems and is suitable for the simple plug-and-play installation of up to eight safety switching devices.

Universal interfaces

The developers have opted for a universal device interface with an eight-pin M12 connector because this means that all common types of safety switching devices can be connected: electromechanical safety switching devices, electromechanical and electronic safety interlocks with one or two-channel control, safety sensors, optoelectronic protective devices (ESPE; via Y- adapter) and control panels. That doesn't just apply to the Schmersal Group's range: it also applies to safety switching devices different manufacturer are simply e.g. B. can be connected via adapter. An additional integrated digital input on each device slot allows the diagnostic signals of all connected safety switching devices to be evaluated.

In practice this means: With the Safety Fieldbox SFB-PN you can really all safety switching devices e.g. B. a plant section, a workplace or a hazardous area. Typical configurations such as two or three safety switching devices or interlocks (for position monitoring of a single or double-leaf protective door and a maintenance flap), a safety light curtain (for area protection of a slot) and a control panel with an emergency stop button can be connected via the field box in the plug-in and play mode to the higher-level safety controller and can also be easily configured via this controller.

This makes the field box a downright ideal system component for safety systems that are based on the Safety Integrated principle – regardless of which controller make is used. At the same time, it is an important component of systems for condition monitoring and predictive maintenance, especially for more complex machines. It also simplifies installation because the use of the M12 power connector to supply the field box - depending on the switching device type and current consumption - allows up to ten safety field boxes with 80 devices to be easily connected in series.

Secure communication and high availability

Communication based on Profisafe is protected against changes, transmission errors, changes in the telegram sequence, etc. The parallel transmission of the safety signals enables the safety switching devices to be freely linked in the Safety control. In addition, all device connections are equipped with a self-resetting fuse element for the line protection fitted. After eliminating the overload at a connection, the fuse element resets itself after a short cooling phase.

With the Safety Fieldbox, mechanical and plant engineering has a particularly versatile solution for the easy installation of safety switching devices and for their integration into the safety circuit. It is by no means the only solution and is not intended to replace the existing range of services, but rather to complement them. The designer therefore has a choice. In the first step, the safe field box for Profinet/Profisafe will be launched on the market, the safe field box for Ethernet IP/CIP safety will follow a little later.

Five installation solutions for optimum machine safety

30.01.2019/XNUMX/XNUMX | Thanks to its newly developed Safety Fieldbox, the Schmersal Group is now able to five different installation solutionsn to protect different machines and systems. This diversity of variants has so far been a unique selling point on the market. This allows machine builders and operators to select the optimum safety concept for their individual systems, especially with regard to cost-effectiveness and efficiency. The following installations are available:

First: IO parallel | This is a universal, cost-effective standard solution with terminals for parallel wiring of safety switching devices. It is suitable for smaller machines, for which only a few switches are required for protection.

Secondly: Safety installation systems PFB / PDM | Installation solutions with a passive distributor module (PDM) or a passive field box (PFB) are available for applications with exclusively electronic safety switching devices. They enable mixed series connection with up to four different electronic safety switching devices per module. Several modules can be interconnected to form larger systems. This solution is suitable for more complex machines and systems and is easy to assemble, fail-safe and requires little cabling.

Third: Safety Fieldbox | The safe field box is suitable for the installation of up to eight different safety switching devices. The safety signals from the connected devices are forwarded to a safety controller for evaluation via the safe Profinet/Profisafe fieldbus interface. The safe field box is simple and inexpensive and at the same time enables very flexible and individually configurable safety solutions for larger machines and systems.

Fourth: SD interface | The "serial diagnostics" interface is used for the transmission of non-safe data when electronic safety switching devices are connected in series. With this solution, the diagnostic signals and the safe signals can be forwarded to the functional controller and the safety evaluation via the passive distributor module PDM, the passive field box PFB or a Y-adapter. For users who do not want to use a bus system on the sensor/actuator level, systems such as the SD interface offer a simple installation solution for series connection in small and medium-sized machines.

Funftens: AS interface | The wiring solution for safety switching devices has an integrated AS-i Safety-at-Work interface. On the basis of an open standard, this safety bus allows the construction of individually scalable safety solutions for different machine sizes with quick and easy installation. In addition, the AS-i safety solution offers extensive diagnostic options and thus enables, for example, early error detection - an important aspect with regard to preventive maintenance and Industry 4.0. The manufacturer has an extraordinarily extensive range of safety components with AS-i interface. All major series can be supplied with AS-i Safety Interface.

All installation solutions also transfer extensive diagnostic data. The operator can thus see exactly which switch in the row triggered a signal. In this way, any faults can be eliminated more quickly and machine downtimes avoided. In addition, individual protection of the safety switching devices is integrated in the Safety Fieldbox and the different variants of PDM and PFB. The wide variety of installation solutions offers the greatest possible flexibility for the user: He can thus choose the optimal wiring system for his individual requirements.

Safe field box with Profinet / Profisafe fieldbus interface

16.10.2018 | The Schmersal Group presents its new Safety Fieldbox SFB-PN-IRT-8M12-IOP, which will be launched in 2019. The safe field box for Profinet / Profisafe systems is suitable for the simple plug-and-play installation of up to eight safety switching devices.

16.10.2018 | The Schmersal Group presents its new Safety Fieldbox SFB-PN-IRT-8M12-IOP, which will be launched in 2019. The safe field box for Profinet / Profisafe systems is suitable for the simple plug-and-play installation of up to eight safety switching devices.

Thanks to the universal device interface with 8-pin M12Plug A wide variety of safety switching devices can be installed: up to eight tumblers of different designs such as electromechanical, electronic or electronic versions with 2-channel control of the tumbler function; Up to eight non-contact protective devices (ESP) such as light curtains and light grids, connectable via Y adapters, as well as up to four BDF200-FB control panels with electronic emergency stop function and three operational command and signaling devices. Through an additional integrated digital input the diagnostic signals of all connected safety switching devices can be evaluated at each device slot. Safety switching devices from other manufacturers can also be easily connected using adapters.

The safety signals from the connected safety switching devices are forwarded to a safety controller for evaluation via the fieldbus interface. PROFIsafe is the functionally safe extension of standard communication via Profinet. Communication based on Profisafe is protected against changes, transmission errors, changes in the telegram sequence, etc. The parallel transmission of the safety signals enables the safety switching devices in the F controller to be linked freely.

Push pull M12 connector now standardized thanks to IEC 61076-2-010?

Push pull M12 connector now standardized thanks to IEC 61076-2-010?

The device connections of the field box are for connecting different devices configurable, so that the greatest possible flexibility is possible when designing security solutions. All device connections have been equipped with a self-resetting fuse element for line protection. After eliminating the overload at a connection, the fuse element resets itself after a short cooling phase.

"The safe field box is a simple and cost-effective installation solution, which at the same time enables very flexible and individually configurable safety solutions for complex machines and systems," says Udo Weber, product manager safety technology. "In addition, the additional transmission of all diagnostic signals from the connected devices enables optimal process transparency".

You might also be interested in...

This is how you build a collaborative robot cell

RFID and Barcodes | Industrial identification

Light barrier, light grid, light curtain for safety

3D Camera | Industrial image processing

Relays & Switches | Discover the possibilities!