In a production of the size and specialization as with Stihl the plant operators and maintenance staff must keep an overview. They no longer waste time searching for software versions or system documentation. Because since 2009 this has been done by the version and data management software Versiondog from Auvesy for the 3000 systems of the professional tool specialist.

In a production of the size and specialization as with Stihl the plant operators and maintenance staff must keep an overview. They no longer waste time searching for software versions or system documentation. Because since 2009 this has been done by the version and data management software Versiondog from Auvesy for the 3000 systems of the professional tool specialist.

Maintenance at Stihl is organized in two parts. Each production area has its maintenance teams, who look after day-to-day business with a very good knowledge of the plant. There is also a central maintenance pool with specialists who support the teams on site when time is tight or special know-how is required. The maintenance staff at the plants in Waiblingen and Ludwigsburg can simply exchange views. The maintenance workers in Switzerland, the USA, Brazil or China, although less frequently, but not less intense, for example, in workshops or by the employees of the in-house equipment manufacturing.

This in-house equipment construction develops and realizes production equipment and plants for the individual domestic and foreign plants. That's one of Stihl's competitive advantages. "In operation, it has the invaluable advantage that the plant manufacturer in the house and therefore quickly available," says Thomas Ruppmann, electrical design at Stihl and continues: "When we build a plant, we have a machine life in the responsibility. Therefore, we have an interest in a high-quality system already during the planning and the construction, which causes few problems. "

Versiondog from the beginning

Thomas Ruppmann is Versiondog user of the first hour: "We do the user management for two, put on the backup jobs and look that the system is running." They get support from the central IT, which also includes the network infrastructure and the server Provides.

Thomas Ruppmann is Versiondog user of the first hour: "We do the user management for two, put on the backup jobs and look that the system is running." They get support from the central IT, which also includes the network infrastructure and the server Provides.

The electrical designer has already worked with the predecessor product "Versionworks" and accompanied the transition to Versiondog. He describes his experience with the Auvesy software as follows: "This comfortable and easy-to-use tool makes our daily work easier."

"At the beginning of the backup age, data management wasn't a problem, at least when it came to finding the latest software version," says Thomas Ruppmann. At that time there were very voluminous programming devices that were brought into production on their own vehicles. “It was clear where the data was,” he recalls. With the start of the data backup on diskette, especially with the USB sticks, it was already more difficult. There was a risk of losing media. Nevertheless, manufacturing and the production environment have always been well organized.

Processes should be optimized

Therefore, the reason for the launch of Versiondog in the year 2009 was not so much the suffering in the search for the current software version, but rather the desire to optimize processes: "We wanted to get better at this point, too." Gradually All facilities and areas of production have been implemented in Versiondog. Today it is about 220 users working with Stihl at the headquarters in Waiblingen with the software. It's not just about the manufacturing itself, but also the building technology works with it: schematics are stored as well as programs for ventilation or lighting control. In addition, the quality assurance officers submit test regulations.

Therefore, the reason for the launch of Versiondog in the year 2009 was not so much the suffering in the search for the current software version, but rather the desire to optimize processes: "We wanted to get better at this point, too." Gradually All facilities and areas of production have been implemented in Versiondog. Today it is about 220 users working with Stihl at the headquarters in Waiblingen with the software. It's not just about the manufacturing itself, but also the building technology works with it: schematics are stored as well as programs for ventilation or lighting control. In addition, the quality assurance officers submit test regulations.

The requirements for these areas are differentiated, and the access rights are assigned accordingly. Because facility management needs different information than production. It is therefore important that Versiondog can be used to assign different access rights. The access rights in equipment manufacturing are handled particularly restrictively, especially when it comes to systems with a high level of expertise. This is why Versiondog is not only used in the running system: "We use the system in equipment construction when the system is being built to archive intermediate statuses," comments Thomas Ruppmann. Sometimes it turns out during commissioning that a section has to be reprogrammed. Then it would be advantageous if a previous version could be used.

Versiondog as a multifunction tool

"In any case, we have a tool that allows us to access all the required information about the system on the spot. This fast access often reduces the downtime of a system, "notes Thomas Ruppermann. With the help of a nationwide WLAN, the program versions of the respective PLC as well as electrical and pneumatic circuit diagrams (Quicktipps) are available on site in all production areas via Versiondog - ie setting notes or documents of more or less exotic assemblies.

The versiondog project had started in a classic way with the backup of PLC software. The safer the handling and operation, the more possibilities the users would have shown. It is also highly appreciated that the required editors are integrated and can be worked in familiar surroundings. "We just had to define the directory or filing structure. The system did not require any programming effort, "says Thomas Ruppmann.

7600 components covered

In the meantime, around 3000 systems have been archived in Versiondog in all German Stihl plants. In total, these are 7600 components. As standard, three components have been defined for each system: Control program, circuit diagrams and documentation. If required, the components can be further structured with subdirectories or supplemented by components for a robot or nutrunner control. Documentation can conceal a great deal of information: PDF documents as well as Excel spreadsheets, basically anything that (in terms of control technology) can occur as a file format. Since the beginning of the data recording a total of 46.000 versions are stored in the archive. The storage requirement on the server is not even 1,5 GB.

In the meantime, around 3000 systems have been archived in Versiondog in all German Stihl plants. In total, these are 7600 components. As standard, three components have been defined for each system: Control program, circuit diagrams and documentation. If required, the components can be further structured with subdirectories or supplemented by components for a robot or nutrunner control. Documentation can conceal a great deal of information: PDF documents as well as Excel spreadsheets, basically anything that (in terms of control technology) can occur as a file format. Since the beginning of the data recording a total of 46.000 versions are stored in the archive. The storage requirement on the server is not even 1,5 GB.

One could ask the question, if there are not annoyingly long processes at work with such packed directories, which delay the quick restart after a standstill. The answer is: "No, because in order to save time, Stihl always downloads only the last version by default. In addition, "says Ruppmann," for example, a comparison of a S7 unit is very fast. "

With the web-based plant status as versiondog feature, current additional information such as installed firmware, MLFB numbers, force values, memory utilization or cycle time overruns can be displayed and localized. This is currently not used by Stihl. With the large number of components, however, the solution sounds very interesting to Thomas Ruppmann: "We are happy to use the opportunity to test the system status once."

The systems are backed up daily at Stihl so that the latest production data is always available. In addition, the backups allow unintentional changes to be detected. They run in the background and do not need to be watched carefully. In the event of abnormalities, someone from the responsible team will be notified immediately by e-mail.

Rarely used service hotline

At Stihl, quality-oriented work includes working with the latest version of the data management software. Updates are imported promptly. As a rating, Thomas Ruppmann wants to add that he rarely has to use the Auvesy service hotline. “The system is stable and can be operated very intuitively.” It speaks for the quality of the product if you don't need support that often.

The straightforward handling of Versiondog is also reflected in the training effort. New employees get along with the system after a short training period and generally the acceptance in the team is very high. According to Ruppmann, colleagues see the benefits every day in their work, as all relevant data is available anytime, anywhere.

Regarding the return on investment, Mr. Ruppermann says: "The advantages of Versiondog are difficult to quantify in euros, since above all the soft factors show the added value. Subjectively, it has become much easier with the software. "The financial saving was also not the main focus in procurement, but the transparent and traceable documentation. Saving effects are a pleasant side effect. "There is no need to search for the latest software version, regular backups are done automatically and the risk of losing data is history."

For Thomas Ruppmann it is clear: "Versiondog is a round tool that makes our work immensely easier. Functionalities such as version comparison are even better than the solutions of the individual device manufacturers. That's what makes the Auvesy software so attractive. "

You might also be interested in...

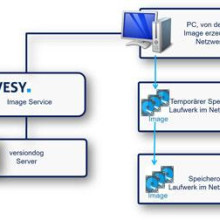

Service for the automated creation of PC images

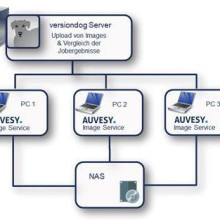

Disk Images quickly secured by automotive suppliers

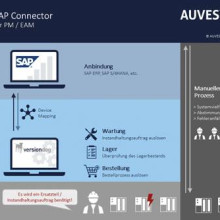

Data management system now with SAP interface for the first time

Integrated image solution in software for data management

Automatic data backup: edit and version projects