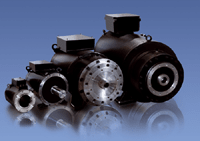

The new generation of DST high torque motors in sizes 135 to 400 from Baumüller is now also available with a hollow shaft or integrated thrust bearing in addition to the solid shaft version. The different versions of the DST motors provide more degrees of freedom in the design and enable the motor to be optimally integrated into the machine concept.

The new generation of DST high torque motors in sizes 135 to 400 from Baumüller is now also available with a hollow shaft or integrated thrust bearing in addition to the solid shaft version. The different versions of the DST motors provide more degrees of freedom in the design and enable the motor to be optimally integrated into the machine concept.

When liquid plastic is forced out of the spray head during plasticizing in extruders, enormous pressure forces act in the direction of the motor shaft. Thrust bearings absorb these forces to compensate for the axial bearing loads and protect the underlying machine unit. Baumüller now offers an integrated thrust bearing for the latest generation of compact and high-performance DST high torque motors in the sizes 135, 200, 260, 315 and 400. This allows pressure forces up to 800 kN to be supported. The integrated bearing in the engine eliminates the need for expensive installation for the mechanical engineer and also eliminates the need for space in machines, since the integration of the bearing into the engine means that it requires less installation space. In addition, the construction simplifies the refitting and disassembly of the machine during maintenance. With the help of a cannulated shaft, the user can push the extruder screw forward, for example by using a spindle.

In addition to the full-shaft design and an optionally integrated thrust bearing, the DST motors of all sizes are also available with hollow shaft. Inside the hollow shaft, for example, can accommodate more components such as a ball screw, which allows a more compact machine concept. In addition, the cooling water for a roller or other media can be passed.

The high-torque motors are high-voltage, permanently excited synchronous motors with a torque spectrum up to 32.000 Nm. This makes the DST motor series with solid shaft, hollow shaft or thrust bearing particularly suitable for applications requiring high torques at low speeds. The high degree of protection IP54 is possible in industrial environments. Within a certain tolerance range, the powerful engines have a good overload capacity. Furthermore, they have very good concentricity properties and due to their compact design they can be effortlessly integrated into existing machine concepts and placed close together.