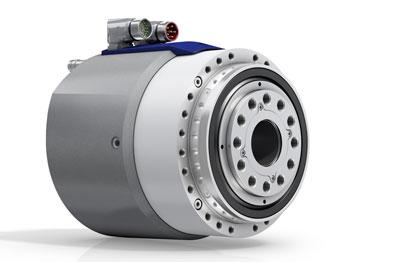

Among other things, Wittenstein will be presenting the “Galaxie” drive system in a compact version. In addition, the company is presenting smart gears that are equipped with industry-standard integrated sensors and have IO-Link connectivity.

Among other things, Wittenstein will be presenting the “Galaxie” drive system in a compact version. In addition, the company is presenting smart gears that are equipped with industry-standard integrated sensors and have IO-Link connectivity.

According to the manufacturer, Galaxie is scientifically proven to be a superior gear type due to its design and recognized in important industries such as high-performance machine tool construction. Responsible for the freedom from backlash, the very good synchronization with high rigidity, torque density and overload capacity is the completely redesigned gear design.

Gear calculation for gears with background graphic

Gear calculation for gears with background graphic

This is characterized by dynamized individual teeth instead of a rigid toothed ring, a tangential and, in the case of load, full-surface, hydrodynamic contact when the teeth mesh, as well as the new type of bearing with a segmented outer ring. There is now a compact version with Galaxie D in size 085 for use in smaller milling heads and handling axes. It fulfills the special requirements for torsional rigidity and freedom from play that prevail there. The ultra-flat Galaxie DF in sizes 110 and 135 will also be presented.

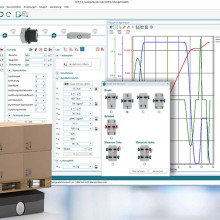

Cynapse functionality and Industry 4.0 capability

The “cynapse” functionality of the smart gear includes a fully integrated sensor module, data output via IO-Link with the resulting I4.0 connectivity and logic functions for actual and threshold monitoring of selectable parameters.

Calculate crown gearbox geometrically and in strength

Calculate crown gearbox geometrically and in strength

The gearboxes can record and save different influencing variables from the process and the operational environment that affect the gearbox during operation and communicate with automation systems and all common IIoT platforms.

You might also be interested in...

Engine and gearbox design energy-efficient and free of charge

Heavy-duty extruder gear for processing plastics

Data exchange in gear manufacturing as the basis for digital twins

Robust and safe drive solutions for continuous conveyors