For bulk transport offers NORD powerful drive systems. Reliable, safe and robust, these guarantee smooth operation even under the toughest environmental conditions. They can be individually controlled for precise, dynamic bulk material feed control.

For bulk transport offers NORD powerful drive systems. Reliable, safe and robust, these guarantee smooth operation even under the toughest environmental conditions. They can be individually controlled for precise, dynamic bulk material feed control.

For the transport of bulk goods, conveyors are required that are in the conveying direction, Mass flow, Conveying length and construction. The drives ensure an uninterrupted flow of material. Belt conveyors are conveyor systems that are used for the constant transport of piece goods and bulk goods, for example in mining, mechanical engineering or plastic and paper recycling. Particularly large conveying lengths, quantities and speeds can be implemented. Belt conveyors are characterized by a circumferential belt made of rubber or plastic and tension members for stability. The conveyor belt is deflected by means of at least two drums, at least one drum being driven and setting the belt in motion by means of looping friction.

Large belt conveyor

The long-life and low-maintenance “Maxxdrive” industrial gear units, in which the bearings and sealing surfaces of the block housing are manufactured in one setting, are suitable for large belt conveyors with high capacity. The latest generation Maxxdrive XT has been supplemented by an application-optimized two-stage bevel helical gear unit - ideal for belt conveyor systems in the bulk goods and minerals industry. The power and speed range was specially tailored to the target industries.

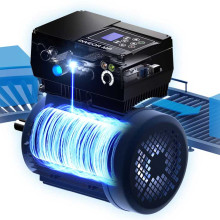

Ultrasonic and radar level sensor with IO-Link for the IIoT

Ultrasonic and radar level sensor with IO-Link for the IIoT

Thanks to the two types, the front or bevel gear units in the foot, flange or slip-on housing can be planned into the conveyor system with parallel axes and at right angles. They are mounted on a swingarm or frame together with a foot-mounted, high-efficiency IE3 engine and are connected to the engine via a hydraulic clutch.

Since most bucket elevator applications generate dust, there is a risk of explosion if the dust is combustible. Here, custom-made motors and geared motors with explosion protection are used, which the drive specialist puts together from its modular system according to individual requirements. A practical maintenance package, consisting of protective measures and monitoring systems, ensures that the investment works even under adverse operating conditions such as continuous operation, dust generation and weather influences.

You might also be interested in...

Heavy-duty extruder gear for processing plastics

Frequency inverter | For the optimal speed on the electric motor

Frequency converter from the modular system for control cabinet + field

Gear motor integrated IE5 + motor in spur gear

Transmission North | The Block Case Inventor