Multifunctional switchgear series for the bulk goods industry

- Hits: 8130

The Schmersal Group In collaboration with Aconno, has developed the prototype of an Industry 4.0 switch for the bulk industry developed. With the switchgear Heavy Duty Switch (HDS) series can wirelessly transmit data over distances of several kilometers in extensive conveyor systems in heavy industry.

The switching devices were specially designed for the bulk industry developed. With the HDS, various functions have been integrated on one platform so that it is suitable for a wide variety of applications. In addition, the platform has extensive international approvals such as UL, CE and CCC. Atex, EAC, Inmetro and IECEx are in preparation.

Areas of application are e.g. B. emergency shutdown, belt misalignment monitoring when conveying bulk materials, end position monitoring in steel production or level measurementin material silos.

Aconno radio transmitter

The emergency stop and belt misalignment switches of the HDS series were radio transmitter integrated by Aconno in order to be able to transmit diagnostic information of the switches faster and more efficiently. Integrated into a mesh network, the status data of the switches can be transmitted from one participant to the next over distances of up to 250 m. Communication over several kilometers is thus possible. This considerably simplifies the monitoring of the safety switches, particularly in the case of large conveyor systems.

Integrated solutions for the mining, bulk and conveyor industries

Integrated solutions for the mining, bulk and conveyor industries

The uniform housing concept is the basis of the new switchgear Platform. It consists of two variants: gray cast iron and Plastic (Thermoset). The plastic version is resistant to aggressive media. The HDS is ideally suited for the bulk goods industry in port logistics, loading and unloading operations and the agricultural industry for processing bulk goods such as fertilizers, minerals and phosphates. The robust gray cast iron design is suitable, for example, for the mining of heavy metallic ores in open-cast mining, as well as for bulk materials and the mining industry.

Functionally there are two basic versions: the Position monitoring and the emergency stop, which is called Bowden cable emergency switch is executed. The basic switch "Position Control" can be flexibly combined with various actuating elements and used for position monitoring of moving machine and system parts.

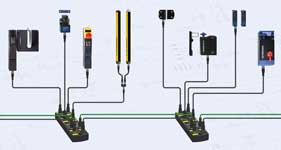

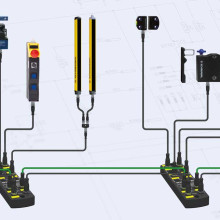

All basic versions of the HDS platform for the bulk goods industry are optionally prepared for a Dupline 2-wire bus and can be connected directly. This means that the switches can be switched and connected in series quickly and easily. The Dupline standard or Dupline Safety 2-wire bus is particularly suitable for reliable signal transmission over long distances.

Monitor switching in real time and online

Each switching can be done in real time and online via any web browser on the PC or Smartphone be tracked and assigned. The data from the cloud can be transmitted directly to the headquarters or to the smartphone of the maintenance and service technician on site using a web application or APP.

Safe field box with reduced wiring effort

Safe field box with reduced wiring effort

Operational disruptions to the conveyor systems in the cloud recorded immediately. The activated safety switching devices can be clearly assigned despite being connected in series. The rectification of the malfunction can be implemented directly by maintenance without loss of time. A lengthy search for faults in the command and control chains of the conveyor systems on the company premises is no longer necessary. With the switching devices, production downtimes can be kept to a minimum and machine availability increased.

Mesh radio network cheaper than fieldbus system

The investment for larger conveyor systems depends on the distance and the environmental conditions Bluetooth-Solution with mesh radio network only a fraction of the system costs of usual fieldbussystems with decentralized structures. Schmersal offers components and complete solutions from a single source for conveying in the bulk goods industry. They protect people and conveyor systems alike. In addition, they ensure the quality control of bulk materials in real time during ongoing conveyor belt operation.

Ultrasonic and radar level sensor with IO-Link for the IIoT

Ultrasonic and radar level sensor with IO-Link for the IIoT

Users from the mining, cement and steel industries as well as bulk goods and agricultural industry can access the holistic systems and solutions worldwide - including a comprehensive service.

You might also be interested in...

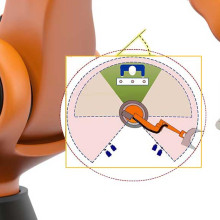

This is how you build a collaborative robot cell

Safe field box with reduced wiring effort

RFID and Barcodes | Industrial identification

Light barrier, light grid, light curtain for safety

3D Camera | Industrial image processing