Safety coupling protects non-destructive tunnel boring machines

- Hits: 8438

Two tunnel boring machines are the largest machines on the construction site Semmering Base Tunnels. The safety clutch EAS-HT from Mayr Antriebstechnik, These Couplings trigger reliably and comprehensibly and protect the drive components sustainably. They cannot be manipulated and the factory-set torque is available again even after disengagement. Recommissioning is also quick and easy, without any additional tools.

Contents

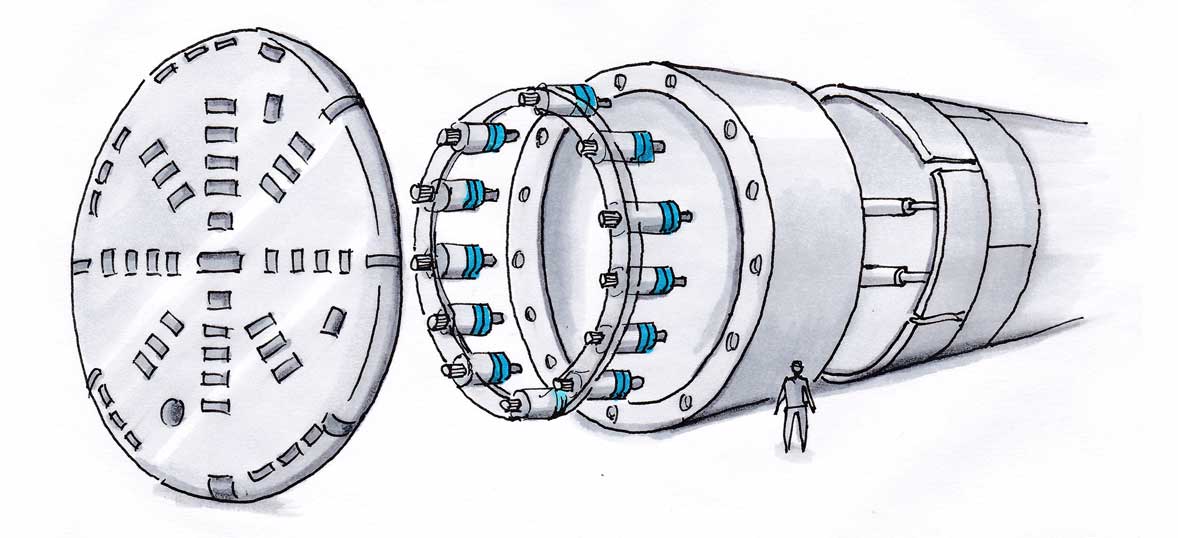

It is considered one of the most important infrastructure projects in the heart of Europe, the Semmering Base Tunnel. From 2026 it connects Lower Austria with Styria. Two tunnel bores are currently being used on the construction site. They are 120 m long and weigh 2500 t and together weigh about as much as 800 elephants.

Overall, the work two drills from Fröschnitzgraben in Steinhaus am Semmering about 9 km towards Gloggnitz through the mountain. Like moving factories underground, they line the excavated tunnel with precast concrete parts. The excavated material, which the machines “spit out” at the rear, is transported to the surface by conveyor belts. On average, a machine covers between 10 and 15 m every day. Every single meter counts. An overload caused by unevenness in the rock, for example, must not stop the drilling machines.

When the safety clutch disengages

“Rest ours safety clutch EAS HT on the construction site, this happens with a defined and traceable torque and only so that it can Transmission, Motor and protects the drive train from damage caused by overload, ”explains Ralph Eple, Product manager at Mayr Antriebstechnik in Mauerstetten. Long downtimes are avoided and the work is sustainable. "The security concept must not be susceptible to manipulation ”, emphasizes the product manager. “This is why we set the torque on our clutches at the factory. So it is available again right after you disengage. The safety aspect does not depend on the restart. "

Extremely high torques and speeds

"The releasing EAS-HT safety clutches are element clutchthat are very well suited for use at high torques and speeds as well as large moments of inertia, ”says Ralf Epple. These overload clutches are based on individual overload elements that are integrated into the flanges. The achievable torque results from the pre-tensioning force of the elements multiplied by the number of elements and the radius on which the elements are arranged.

Thanks to the modular concepts not just clutches that are tailored to the application can be built. With these overload clutches, in particular, much higher torques can be achieved than with a central disengaging mechanism. Mayr has safety clutches of the EAS-HT series as standard with a torque of up to 440.000 Nm. But that does not mean that the possibilities are exhausted: The modular structure actually sets no upper limits.

Transmit torque positively

With the EAS-HT clutch, the individual overload elements transmit the torque in a form-fitting manner in trouble-free operation. In the event of an overload, they separate the drive and output in fractions of a second with high switch-off and repeat accuracy almost free of residual torque. Only the friction of the high-quality pressure flange bearing is effective. The kinetic energy of the rotating masses stored in the system can run out freely.

With the EAS-HT clutch, the individual overload elements transmit the torque in a form-fitting manner in trouble-free operation. In the event of an overload, they separate the drive and output in fractions of a second with high switch-off and repeat accuracy almost free of residual torque. Only the friction of the high-quality pressure flange bearing is effective. The kinetic energy of the rotating masses stored in the system can run out freely.

The element coupling remains separated from the drive until it is easily and quickly re-engaged using hydraulic, pneumatic, mechanical or electromechanical devices or by hand using a hammer. No other tool is required. Release clutches can cope with long deceleration times of the drives after responding. When defining the permissible run-out time, only the robust coupling bearings have to be taken into account. “Our couplings are designed so that the drilling stroke can be completed with the clutch disengaged, if necessary,” explains Ralf Epple.

Overload protection is non-destructive and safe

In contrast to other overload systems that z. B. work with pressurized hydraulic oil or shear bolts, the EAS-HT safety clutch is ready for operation again immediately after eliminating the cause of the overload. It is not damaged and can handle several hundred overload cases. In addition, the torque at which it disengaged can be traced. "With other systems, the evidence is also destroyed after the overload operation, so to speak, and there is uncertainty about the disengagement torque," says Mr. Epple. “In addition, the destroyed components have to be replaced after an overload.

Slipping clutch and overload clutch limit torques

Slipping clutch and overload clutch limit torques

In addition to the costs and system downtime, the necessary components must also be available. There is also the know-how for the Recommissioning necessary. There is a risk that the torque will be set incorrectly, the consequences of which are too great, especially in the field of tunneling and mining. ”In terms of size and weight, the EAS-HT from Mayr Antriebstechnik also scores. “The new, compact versions were specially developed for the tunnel area. They have roughly the same weight and outside diameter as other overload systems, ”adds the product manager.

Tested and found good

“We have now several thousand couplings in use and experience with setting values, ”says Ralf Epple. Before a coupling leaves the factory in Mauerstetten, it is thoroughly tested and precisely adjusted to the required value. Mayr also offers a wide range of modern testing options. You can fall back on decades of experience in construction and development. Even if existing systems are retrofitted, the performance can be increased significantly with Mayr couplings.

You might also be interested in...

High-performance brake wind turbine with monitoring

Robco robot kit with safety brake from the construction kit

Safety brakes: innovations + tips for installation

Predictive maintenance for clutches and brakes

Shaft coupling without play, precise and smart

Compensating coupling | For axial, radial and angular offset

Simone Dauer is a press officer at Chr. Mayr GmbH + Co. KG, Mauerstetten