for food and beverage industry

Drives, materials, machine elements and automation technology according to special, strict standards - regionally and nationally

Image: Harting

for food and beverage industry

Drives, materials, machine elements and automation technology according to special, strict standards - regionally and nationally

Image: Harting

Here you will find new products and solutions for food technologists, engineers and other food technology professionals. In the field of the food industry, not only are ecological and economic resources converted into food and raw materials processed, but a high nutritional value and enjoyment value can also be achieved.

There are the following processes in food technology for the production of food ingredients: Mechanical processes like crushing, pressing, mixing; thermal processes such as heating and cooling; biological processes such as alcoholic fermentation or use of bacteria and fungi as well chemical processes how to coagulate proteins. This is implemented with specially approved machines. Drives, Machine Elements, Automation services, Materials etc. for food technology must therefore special and strict standards, regional, state or international. Food technology is next to that Medical Technology one of the industries with the highest circulation.

Below you will find components, systems and applications that washdown capable and FDA allowed are. The devices, machines and systems for processing raw materials for beverages and foodstuffs have to withstand the harsh cleaning processes.

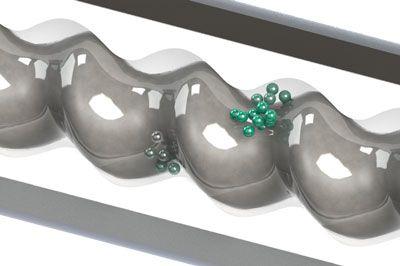

14.03.2024/XNUMX/XNUMX | On the Anuga Foodtec 2024 presents Schaeffler linear guides for food technology. Such profile rail guides are used in a variety of linear movements when processing and packaging food. An example is the four-row ball recirculating unit from the KUVE..B series.

14.03.2024/XNUMX/XNUMX | On the Anuga Foodtec 2024 presents Schaeffler linear guides for food technology. Such profile rail guides are used in a variety of linear movements when processing and packaging food. An example is the four-row ball recirculating unit from the KUVE..B series.

07.02.2024 | NIR spectrometer from Polytec allow reliable and non-destructive measurements of a wide variety of ingredients directly in the production lines of e.g. B. dairy products and baked goods, meat products, confectionery or cooking oils. For olives, oil and acidity can be determined directly after harvesting on the conveyor belt.

07.02.2024 | NIR spectrometer from Polytec allow reliable and non-destructive measurements of a wide variety of ingredients directly in the production lines of e.g. B. dairy products and baked goods, meat products, confectionery or cooking oils. For olives, oil and acidity can be determined directly after harvesting on the conveyor belt.

Igus is a member of the EHEDG and developed the first linear sliding guide that was consistently based on the hygienic design guidelines. This is ensured by FDA-compliant materials such as the high-performance polymer, high-alloy stainless steel and the flushable internal construction of the slide. The Drylin W linear guide features a gap-free design.

Igus is a member of the EHEDG and developed the first linear sliding guide that was consistently based on the hygienic design guidelines. This is ensured by FDA-compliant materials such as the high-performance polymer, high-alloy stainless steel and the flushable internal construction of the slide. The Drylin W linear guide features a gap-free design.

17.05.2023 | Kollmorgen is expanding its AKMTM servo motor portfolio with a new high-performance servo motor. The focus of its development was cleanability, longevity and versatility. The motor features a hardened, anodized aluminum surface and offers machine designers a cost-effective and hygienic alternative to stainless steel.

17.05.2023 | Kollmorgen is expanding its AKMTM servo motor portfolio with a new high-performance servo motor. The focus of its development was cleanability, longevity and versatility. The motor features a hardened, anodized aluminum surface and offers machine designers a cost-effective and hygienic alternative to stainless steel.

At the Interpack booth of Mitsubishi Electric is all about the chocolate in a modular, open and fully integrated line. The advanced quality control of chocolate bars and their packaging will be demonstrated together with partners industrial robots.

At the Interpack booth of Mitsubishi Electric is all about the chocolate in a modular, open and fully integrated line. The advanced quality control of chocolate bars and their packaging will be demonstrated together with partners industrial robots.

Schmersal introduces the new Safety light barriers SLB440 series. This is particularly suitable for hygiene-sensitive applications in the packaging and food industries such as dairy farming and meat processing. A single-beam light barrier from the SLB series is very compact with a diameter of 62 mm and a height of 115 mm. They are therefore ideal for use on thermoforming machines for packaging.

Schmersal introduces the new Safety light barriers SLB440 series. This is particularly suitable for hygiene-sensitive applications in the packaging and food industries such as dairy farming and meat processing. A single-beam light barrier from the SLB series is very compact with a diameter of 62 mm and a height of 115 mm. They are therefore ideal for use on thermoforming machines for packaging.

When it needs to be extra precise in corrosive or special atmospheric operating conditions, you need ones designed for it Sensors and encoder reliable compensating couplings. The encoder coupling Sensorfit from Schmidt coupling meets this requirement, is resistant to high temperatures and designed for the requirements of the food industry.

When it needs to be extra precise in corrosive or special atmospheric operating conditions, you need ones designed for it Sensors and encoder reliable compensating couplings. The encoder coupling Sensorfit from Schmidt coupling meets this requirement, is resistant to high temperatures and designed for the requirements of the food industry.

For his 75th company anniversary Jumo come up with something very special: a own anniversary beer brewed on a specially developed and manufactured highly efficient brewing system, in which the relevant for the brewing industry Jumo products are installed. The result is a golden yellow, tasty pilsner with a pleasant bitter note.

For his 75th company anniversary Jumo come up with something very special: a own anniversary beer brewed on a specially developed and manufactured highly efficient brewing system, in which the relevant for the brewing industry Jumo products are installed. The result is a golden yellow, tasty pilsner with a pleasant bitter note.

The new detectable keypads has Kipp for the food technology and pharmaceutical industry designed. Leave with them for contamination in the manufacturing process prevent major failures. When small splinters come loose from damaged components and get into the products, it is often the consumers who first discover the fault. Expensive product recalls are the result.

The new detectable keypads has Kipp for the food technology and pharmaceutical industry designed. Leave with them for contamination in the manufacturing process prevent major failures. When small splinters come loose from damaged components and get into the products, it is often the consumers who first discover the fault. Expensive product recalls are the result.

Machine elements in the food industry must meet media resistance, freedom from lubricants and corrosion. In order to be able to quickly identify fractions in the event of damage to a system, Igus has now developed two new optically and magnetically detectable materials for its plain and spherical bearings with "Iglidur FC180" and "Igumid FC". The materials are FDA and EU10 / 2011 compliant.

Machine elements in the food industry must meet media resistance, freedom from lubricants and corrosion. In order to be able to quickly identify fractions in the event of damage to a system, Igus has now developed two new optically and magnetically detectable materials for its plain and spherical bearings with "Iglidur FC180" and "Igumid FC". The materials are FDA and EU10 / 2011 compliant.

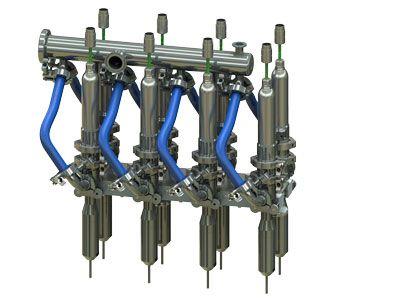

Food that is packed in sachets, stick packs or pouches is popular due to its quick availability in portions. The trend towards smaller packaging sizes for cosmetic products is also noticeable. Viscotec offers dosing and filling systems for this, in order to be able to dose the most difficult liquids reliably, non-destructively and with high precision.

Food that is packed in sachets, stick packs or pouches is popular due to its quick availability in portions. The trend towards smaller packaging sizes for cosmetic products is also noticeable. Viscotec offers dosing and filling systems for this, in order to be able to dose the most difficult liquids reliably, non-destructively and with high precision.

technical articles

technical articles

The production of bread rolls in convenience FoodArea is a major logistical and, above all, production-related challenge. Automation plays an important role here. By using the Hygienic dispenser from Viscotec The precise application of chunky spreads or high-viscosity butter is possible.

A German vegetable processing plant found that one of its transport facilities had an increased consumption of rolling bearings. After an average of only two weeks, the bearings had to be replaced on a conveyor belt. This resulted in increased maintenance and unexpected downtime. NSK has solved the problem.

A German vegetable processing plant found that one of its transport facilities had an increased consumption of rolling bearings. After an average of only two weeks, the bearings had to be replaced on a conveyor belt. This resulted in increased maintenance and unexpected downtime. NSK has solved the problem.

Success Story

Success Story

With his X-ray inspection systems "Dylight" enables Minebea Intec safe and reliable inspection of raw materials and packaged products in the food industry. The continuous development of the systems not only increases the efficiency, but also the flexibility in the selection of possible packaging materials.

The PET-P material “Ertalyte” from Quadrant sometimes has better properties than the widely used POM and can replace it in many cases. Compared to POM, PET-P has less wear and better dimensional stability. In the Sahlberg Polymer Center, the material is tailored and processed according to the individual wishes of the customer. Users receive Ertalyte adapted to their needs and can thus directly process the semi-finished product or install the finished part.

The PET-P material “Ertalyte” from Quadrant sometimes has better properties than the widely used POM and can replace it in many cases. Compared to POM, PET-P has less wear and better dimensional stability. In the Sahlberg Polymer Center, the material is tailored and processed according to the individual wishes of the customer. Users receive Ertalyte adapted to their needs and can thus directly process the semi-finished product or install the finished part.