Connectors for the three zones of the food industry

- Details

- Hits: 11940

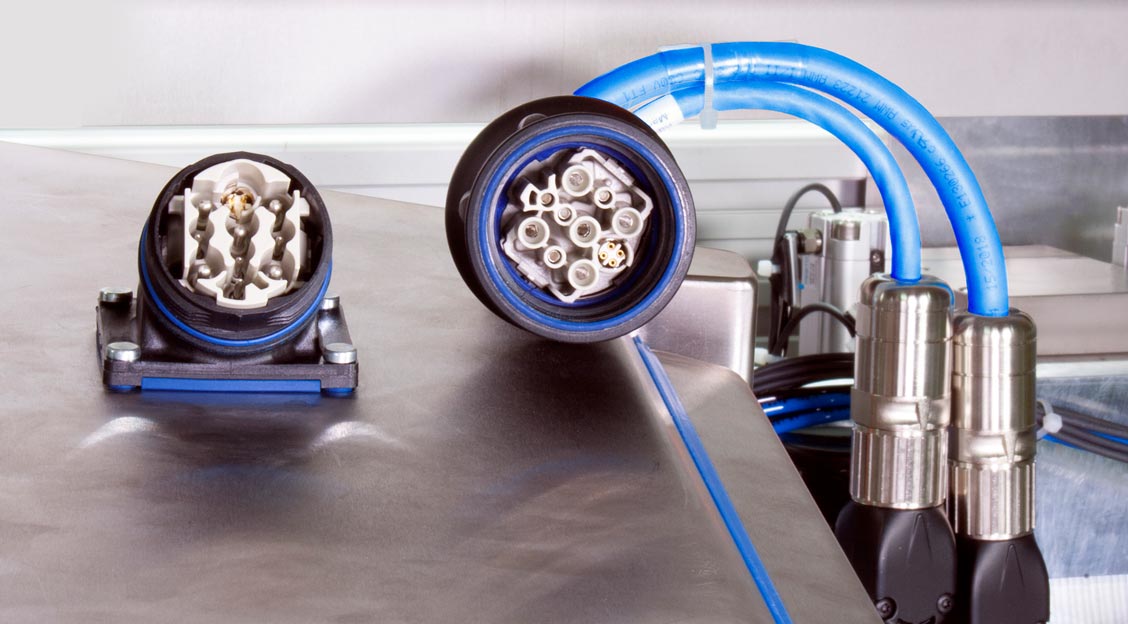

Food producers stand by that Connectors So far, use in sensitive areas has often been skeptical. They fear that interfaces with their outlines will break through the easily washable, smooth surfaces. But you need them in the product-related area for the Cleaning. For such applications Harting an Special connector developed. The Han F + B withstands intensive cleaning.

Contents

- Electrical connection technology in the spray zone

- Resistant to aggressive cleaning chemicals

- Connectors increase flexibility in plant design

- Connectors in the food industry

When operating systems in the food industry, no substances that are hazardous to health may enter the food. Processing and packaging machines must therefore be designed so that they facilitate cleaning and the formation of Dirt nests prevent. That sounds easy, but it is not. This is a challenge for many production managers in the industry.

Clutches and brakes Use in food technology

Clutches and brakes Use in food technology

The Product zone is the zone in direct contact with the food. It places the highest demands on machines and components. This area is often kept small in order to reduce the cleaning effort. Smooth surfaces of the products used here are optimal. Bacteria have no chance of settling here. Because electromechanical interfaces interrupt the smooth surfaces, they are preferably placed outside this zone.

Electrical connection technology in the spray zone

Also in the squirt stage food manufacturers connectors instead of the solidwiring often considered risky. Cleaning chemicals are sometimes used here, which put a lot of strain on the material. High-pressure cleaners also regularly act on the systems with high pressure and hot water. As a result, seals and cable glands on the connector can lose their protective effect for the inside of the housing.

Also in the squirt stage food manufacturers connectors instead of the solidwiring often considered risky. Cleaning chemicals are sometimes used here, which put a lot of strain on the material. High-pressure cleaners also regularly act on the systems with high pressure and hot water. As a result, seals and cable glands on the connector can lose their protective effect for the inside of the housing.

Also for Packaging automation (PA), manufacturer of traysealers in Knutsford, Great Britain, the use of connectors used to be particularly risky. There have been cases where sealing rings and cable glands have lost their protective function after using highly effective chemicals and high-pressure cleaners. For this reason, PA has been using Hartings for several years Special connector Han F + B.

"With the connector, we were able to solve a number of design challenges on our own machines," reports Steve Woodhead, development engineer at PA. The connectors thus enabled standardization on the lower part of the machine. "If a customer wants to change an option, we can easily change the inserts without having to redesign the entire metal structure of the traysealer," says Woodhead. The use of connectors also made it easier to quickly connect components such as suction systems.

Han F + B connectors in the video

Resistant to aggressive cleaning chemicals

The special connector from Harting transmits power and signals in the spray zone. In this particularly hygienically sensitive environment, system parts can come into contact with food. Such foods will not come back into the Product stream recycled, however, there may be residues on the machine components. This zone therefore requires connectors that can withstand high-pressure cleaning and aggressive chemicals and thus protect the electrical connection from water under high pressure. After cleaning, no residues may remain that could lead to the formation of germs.

The special connector from Harting transmits power and signals in the spray zone. In this particularly hygienically sensitive environment, system parts can come into contact with food. Such foods will not come back into the Product stream recycled, however, there may be residues on the machine components. This zone therefore requires connectors that can withstand high-pressure cleaning and aggressive chemicals and thus protect the electrical connection from water under high pressure. After cleaning, no residues may remain that could lead to the formation of germs.

The Housing of the Han F + B has an easy-to-clean design with large radii and smooth surfaces. It was designed based on the guidelines of the European Hygienic Engineering & Design Group (EHEDG). Special housings and seals protect the electrical connections with IP69K against high pressure and steam jet cleaning. In addition, the function-related gaps in connectors are covered. The housing material is FDA 21 approved. The certification according to Ecolab confirms the resistance to aggressive cleaning chemicals.

In addition to the Han F + B inserts with nine contacts, there are over twenty different inserts available for the Han 3 A size: The range extends from RJ45 interfacen to signal inserts with a maximum of 21 poles to power contacts for currents of up to 40 A. With the diverse portfolio, users can flexibly install electrical interfaces even in a small space. You don't have to Glandin am switch cabinet open to decouple field devices. Time-consuming loosening and re-installation of fixed wiring is no longer necessary. With plug connectors, system installations can therefore be carried out more quickly, Tool change and service calls are shorter.

Connectors increase flexibility in plant design

The demands on connectors in the product-free zone. There is no direct contact between the food and the system. Nevertheless, the components should be easy to wash off and disinfect. The connectors of the industry standard Han B are suitable for this. They have at least protection class IP65 and are therefore suitable for many applications.

Another option are stainless steel housings from the Han Inox series. If the product-free zone is cleaned together with other areas, the components can be exposed to noticeable chemical stress. Stainless steel is suitable as the material for the housings of such connectors because it is particularly resistant to corrosion and has a smooth surface. This allows the surface to be cleaned thoroughly and without residue.

The Stainless steel case Han-Inox are particularly resistant to chemical cleaning in the food industry. The interior with the contacts is safely protected against splash water. With the housing of the larger size 10 B, the user can also benefit from inserts from the Han-Modular series.

With partner Kuka from Harting connector to robot connectivity

With partner Kuka from Harting connector to robot connectivity

The series consists of a large number of inserts in standard dimensions, which cover the various lifelines of the industry. It ranges from the Han Gigabit module for fast data transmission via power modules with z. B. 16 A up to high current modules with 100/200 A as well as pneumatic contacts for compressed air. The right system can be put together for (almost) every requirement.

Alternatively, compact Han 3A stainless steel housings can also be used. They have degree of protection IP67 and take up little space. This means that they can be used very well as motor connectors, for example.

High-performance plastic as an alternative

Plastic offers an alternative to stainless steel outside the high-pressure cleaning production area. In addition to the Han F + B connector for the spray area, Harting also offers the Han-Eco series for the product-free zone. It has non-corrosive properties of the high-performance plastic reinforced with glass fiber. Han-Eco uses housings with high mechanical robustness in protection class IP65. At the same time, plastic is very light. The combination with contact inserts of the Han Modular series Han-Eco has the advantage that there is one module more space in each size than in the standard metal housing. This saves weight and space.

Docking frames are useful for setup-intensive applications with regular tool changes such as format changes on thermoforming machines. Such frames serve as a holder for Han-Modular. Different modules for the transmission of data, power, signals or compressed air can be placed next to each other.

With over one hundred different modules, the modular connector range from Harting offers an almost infinite number of possible combinations and a high degree of flexibility. The interfaces are connected or separated together with the tools or machine elements through the docking frame. Such docking systems can be set up modularly. They can be adapted to the respective application.

Connectors in the food industry

Harting has published an informative white paper on the subject of connectors in the food industry. The document gives the user an overview of the requirements for connectors as they result from the zoning in food production (e.g. EN 1672-2). In addition, there are instructions for a suitable design of interfaces for machines and in the food industry, the materials to be used and instructions for cleaning agent resistance ConnectorsComponents.

Zones of food production

The manufacturing processes in the Food industry take place in three different zones: product zone, spray zone and product-free zone.

Product zone

All parts of the system and components that come into direct contact with food must be washable, disinfectable, corrosion-resistant, non-toxic, non-absorbent, smooth, continuous or sealed. Connectors usually do not come into direct contact with food and are therefore rarely found in this area.

Spray zone

Food can also come into contact with the components, but is not fed back into the product flow. Because this area also needs to be cleaned regularly, the criteria for the product zone should be used as a guide to ensure a high level of hygiene here too.

Product-free zone

No direct contact between food and plant components. These components must be corrosion-resistant and easy to wash and disinfect.

You might also be interested in...

industrial housing | Indoor and outdoor control boxes

Electrical Wires | From cable to assembly

RFID and Barcodes | Industrial identification

Ethernet switches | The data driver in the network

Reduce carbon footprint | That's how it's done!

Charging plug, charging cable | For the electric car

Florian Hackemeier is Team Leader Product Management Han Connectors at Harting.