Safety control protects the sausage processing plant

- Details

- Hits: 7229

During the Food industry Flexibility is becoming an increasingly important characteristic. At the same time, companies prefer security systems that offer operational efficiency and cost advantages in addition to the necessary security function. The system for processing cold cuts from shows how these requirements can be implemented Weber mechanical engineering, They were secured with a modular safety control from Schmersal, The service package included commissioning and validation by the service division tec.nicum.

During the Food industry Flexibility is becoming an increasingly important characteristic. At the same time, companies prefer security systems that offer operational efficiency and cost advantages in addition to the necessary security function. The system for processing cold cuts from shows how these requirements can be implemented Weber mechanical engineering, They were secured with a modular safety control from Schmersal, The service package included commissioning and validation by the service division tec.nicum.

In the food industry, machines and systems are often in interlinked overall systems involved. Machines must also be increasingly more flexible than they were a few years ago because product life cycles are becoming increasingly shorter. More and more special sizes and promotional items ensure this. Retailers and end consumers expect a greater variety of products. Weber Maschinenbau is a system provider for cold cuts applications in Breidenbach, Hesse. The company develops and manufactures complete lines for the production of cold cuts. The linear modules built into it are intelligently networked.

Seven machine modules need safety functions

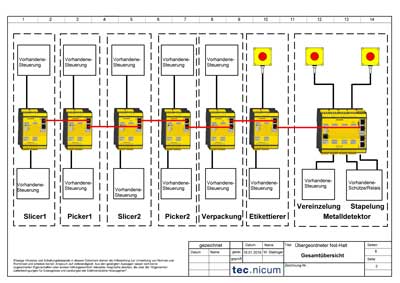

Such complex systems for processing cold cuts have now been made with the Safety control PSC1 and decentralized I / O expansion modules secured by Schmersal. The system consists of seven modules, including two slicers for cutting the products into slices, two pickers for placing the slices in layers in the packaging, one thermoforming packaging machine each, a labeler and end-of-line equipment for final inspection and stacking.

Such complex systems for processing cold cuts have now been made with the Safety control PSC1 and decentralized I / O expansion modules secured by Schmersal. The system consists of seven modules, including two slicers for cutting the products into slices, two pickers for placing the slices in layers in the packaging, one thermoforming packaging machine each, a labeler and end-of-line equipment for final inspection and stacking.

The system thus extends over a length of around 50 m. The slicers cut the cheese and sausage at up to 2000 slices / min. You and the other machine modules must be equipped with a Emergency stop command device .

Clutches and brakes Use in food technology

Clutches and brakes Use in food technology

The emergency stop function must be designed in such a way that dangerous movements and the operation of the machine are stopped in a suitable manner after the emergency stop command device has been actuated. Emergency stops are divided into stop categories depending on the technical conditions: Stop category 0 - which applies to the Weber Maschinenbau system - requires the machine to be stopped immediately by immediately switching off the power supply.

Eight expansion modules for a safety controller

Overall are tight 30 emergency stop command devices Installed. The machine must be able to be stopped at any point. So it was necessary to develop a concept for the safe signal evaluation of the devices.

Overall are tight 30 emergency stop command devices Installed. The machine must be able to be stopped at any point. So it was necessary to develop a concept for the safe signal evaluation of the devices.

The safety controllers PSC1 can be used efficiently, especially for complex tasks. The basic components of these controllers are the two freely programmable compact controllers PSC1-C-10 and PSC1-C-100. In the basic version, these have 14 safe inputs (up to PL e according to ISO 13849 or SIL 3 according to IEC 61508), two safe Relaisoutputs, four safe semiconductor outputs, two message outputs and two pulse outputs for contact-based sensors.

There are safe options for both variants IO expansion modules, which is centrally located in switch cabinet and can be installed decentrally. The decentralized modules communicate with the compact controller via Ethernet SDDC (Safe Device to Device Communication). In addition, the Save Drive Monitoring Module (SDM) can be used to safely monitor up to twelve axes using many functions. This means that the safe monitoring of the drive with all safety functions such as stopping, positioning, safe switching off or moving can be integrated into the control.

Light barrier, light grid and light curtain for safety

Light barrier, light grid and light curtain for safety

Six extension modules were connected to the PSC1-C-100 via an internal safety-oriented Ethernet bus for the safe evaluation of the signals of the emergency stop elements. If an emergency stop is activated on one of the machines, all other machines in the line are switched off via the control.

Wiring effort significantly reduced

The effort for the cabling The safety control PSC1 and the networking of the machines in the safety chain via the Ethernet bus was considerably reduced. "We implemented a simple, user-friendly and very fast security solution," says Waldemar Stetinger, Application engineer at Schmersal. “Does one of the seven machines have to be replaced because For example, if the machine is converted or expanded for a new product, the modular safety components can be quickly modified ”. The PSC1 is also very easy to replace. Programs created are saved on your SD memory card. There is no need for new programming when replacing the hardware.

The effort for the cabling The safety control PSC1 and the networking of the machines in the safety chain via the Ethernet bus was considerably reduced. "We implemented a simple, user-friendly and very fast security solution," says Waldemar Stetinger, Application engineer at Schmersal. “Does one of the seven machines have to be replaced because For example, if the machine is converted or expanded for a new product, the modular safety components can be quickly modified ”. The PSC1 is also very easy to replace. Programs created are saved on your SD memory card. There is no need for new programming when replacing the hardware.

Simple gateways for the industrial Internet of Things

Simple gateways for the industrial Internet of Things

“The line with the PSC1 control has been in operation with our customer for almost a year and a half; he has now ordered a second with the safety control. It was put into operation in 2019 and the customer is very satisfied. For us this means that it is a good security solution, ”explains Dennis Kasek, Project manager at Weber Maschinenbau.

Including commissioning and validation

The Service division Tec.nicum von Schmersal was also involved in implementing this security solution. The Tec.nicum took over the commissioning and validation including the documentation. "The validation according to EN ISO 13849-2 still receives too little attention," says Tobias Keller, Safety Consultant at Tec.nicum.

Aconno Bluetooth module production started at Schmersal

Aconno Bluetooth module production started at Schmersal

“It shows that the design of the safety-related parts of control systems meets the requirements of EN ISO 13849-2. “The early integration of the validation prevents costly errors in the design. In addition, the carefully carried out validation is a relief that should not be underestimated when implementing measures ordered by the authorities or in legal proceedings ”.

Dennis Kasek's conclusion on the PSC1 Safetycontrols: "The networking of the individual modules and the low cost of cabling are a clean affair".

You might also be interested in...

This is how you build a collaborative robot cell

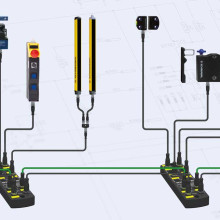

Safe field box with reduced wiring effort

RFID and Barcodes | Industrial identification

Light barrier, light grid, light curtain for safety

3D Camera | Industrial image processing