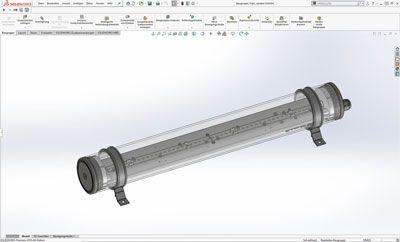

Alfred Pracht relies on CAD software Solidworks for luminaire development

- Details

- Hits: 7711

Good lighting in the right intensity, but also the right color is immensely important for an optimal working environment. Industrial lights also have to be robust and comply with many regulations. Alfred Pracht Lichttechnik also has high standards when it comes to design. When developing its products, the company relies on the CAD software "Solidworks". Dassault Systèmes, managed by the system house Coffee.

Alfred Pracht produced his first luminaire 1953 on the ground floor of his residential building. The first bestseller were the well-known roundish "basement lights" with a protective grid made of metal. Since 2011, Jonathan Pracht, the third generation of the founding family, has been represented on the management board of today's Alfred Pracht Lichttechnik GmbH, which employs around 140 employees.

Alfred Pracht produced his first luminaire 1953 on the ground floor of his residential building. The first bestseller were the well-known roundish "basement lights" with a protective grid made of metal. Since 2011, Jonathan Pracht, the third generation of the founding family, has been represented on the management board of today's Alfred Pracht Lichttechnik GmbH, which employs around 140 employees.

Luminaires in industrial environments are exposed to a wide variety of conditions and still have to function reliably. Often they are hung very high in halls, so that the maintenance of the bulbs is often relatively expensive. Such luminaires should perform their duties for many years without complaint. They often have to be extremely dust- and watertight - for example, so that they can be cleaned with the high-pressure cleaner.

Already Alfred Pracht was uncompromising in the quality of his products. Added to this was the innovation, which has always played a major role in the company's history, leading to the founding of the Pracht Institute of Technology in the year 2015. The development center is intended to strengthen research, development and the exchange between university development and the company.

Up to 95 percent of renewable resources

Sustainability also plays a very important role in the development of new luminaires; the proportion of renewable raw materials in the Pracht luminaires can be up to 95%. For this purpose, in cooperation with universities even special plastics from renewable raw materials, such as cornstarch, developed that still have to meet the high demands of the industry. Another common field of research is heat-conductive, but electrically insulating plastic materials, which would facilitate, among other things, the conversion of existing lighting series.

Sustainability also plays a very important role in the development of new luminaires; the proportion of renewable raw materials in the Pracht luminaires can be up to 95%. For this purpose, in cooperation with universities even special plastics from renewable raw materials, such as cornstarch, developed that still have to meet the high demands of the industry. Another common field of research is heat-conductive, but electrically insulating plastic materials, which would facilitate, among other things, the conversion of existing lighting series.

Customers can be found in a wide variety of industries, from transport companies to the food industry, such as Krombacher or Coppenrath + Wiese.

Intuitive operation even for the inexperienced

In 2013, the company launched Solidworks licenses from Dassault Systèmes. Henning Keitel, developer and designer at Pracht, describes his experiences: "Solidworks helps you get started right away. The operation is intuitive, even if you are not yet familiar with all functions - the commands are there, where you expect them. In product development, we have to make many small changes in the process, which is very good with this CAD solution. "

Expansion with PDM software

Since the luminaires must comply with EU directives - even with special shapes for individual customers - and all changes must be documented in accordance with these guidelines, Henning Keitel and his colleagues are currently considering the introduction of Solidworks PDM: "So far we are storing a lot of data in the SolidWorks properties.

Since the luminaires must comply with EU directives - even with special shapes for individual customers - and all changes must be documented in accordance with these guidelines, Henning Keitel and his colleagues are currently considering the introduction of Solidworks PDM: "So far we are storing a lot of data in the SolidWorks properties.

For the input, we worked with Coffee to develop a solution that allows a simple input via an attribute mask. So we have for each item and each module a property window in which we can store data such as product family, item number or angle of the optics. Of course, in a PDM system, that would be even more convenient, not to mention the other benefits that PDM offers, such as better collaboration, audit compliance, and so forth, "says Henning Keitel.

"The associativity between components, assemblies and drawings is very practical," says the development engineer. "It often happens that we make minor changes to a customer, for example, the suspension of the luminaires. This is very easy to implement thanks to associativity. If you change the component, the assembly and especially the drawings adapt automatically and you can quickly pass on the drawings to the supplier to make the new parts. "

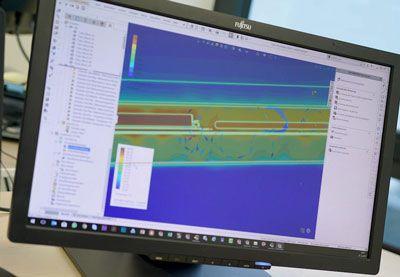

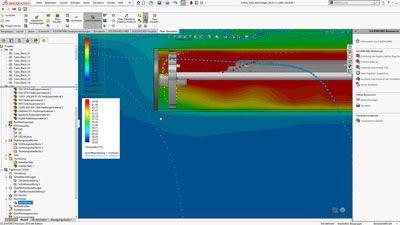

Flow and heat simulation for LED development

For the luminaire manufacturer, the flow and heat simulation integrated in Solidworks has gained greatly in importance with the triumph of the LED. While efficient, they also generate a lot of light over a very small area. This leads to a very selective heat development, which must be reliably dissipated. Thus, housing and heat sink design are becoming increasingly important. An important simulation component is the heat radiation behavior of the luminaires when dust is lying on them.

“We can save a lot of time and money with Solidworks Flow Simulation,” explains Henning Keitel, “because we can replace real measurements on prototypes that are difficult to produce with numerical simulation. We have a VDE-certified temperature laboratory, which is however very busy. Every measurement that we can save relieves the burden on the laboratory. We carried out series of measurements and it turned out that the simulation depicts reality very well. ”

Thermal simulation defuses hotspots

LED technology also requires changes to existing series because many of these series, which have often been sold for many years, are now being converted to the new technology. Again, thermal simulation is used because it shows exactly where changes are needed to defuse hotspots. "In addition, the LEDs have a different radiation behavior and we have to check the lighting," says the designer.

LED technology also requires changes to existing series because many of these series, which have often been sold for many years, are now being converted to the new technology. Again, thermal simulation is used because it shows exactly where changes are needed to defuse hotspots. "In addition, the LEDs have a different radiation behavior and we have to check the lighting," says the designer.

The Pracht designers use Solidworks Composer to create visualizations and animations for the documentation. "Our experience is very positive," says Raphael Eisenberg, who is responsible for marketing at Pracht. "We can quickly and easily create illustrations from the CAD data for operating and assembly instructions, as well as manufacturing instructions. In discussing with suppliers, we use Composer representations to easily explain a new solution. So the other person understands faster what we want. On the other hand, we can make better use of supplier know-how to optimize our products. The Composer enables us, among other things in internal meetings, to present new designs better. "

Visualization tool saves money

But in terms of visualization Raphael Eisenberg continues: "A product photography for marketing purposes, if you need several experiments, quickly costs 1500 Euro for a single image - that saves us the visualization with Solidworks Visualize a lot of money and time. Scribbles in brochures to show specific product features quickly cost 800 to 1000 Euro, which we create today with Visualize and Composer. "

The new visualization module, which is included in all Solidworks licenses, offers very good results with simple operation. The developers are currently testing the professional version of the renderer, which enables you to define your own light sources. This in turn allows the calculation of the real light emission from a luminaire. This enables the developers to recognize unwanted reflections and to eliminate any technical impairments, such as those that often arise when converting to LEDs, even before the first prototypes are built.

Good care by system house

With Coffee as a system house, the lighting manufacturer has been working together ever since Solidworks came into the house. Henning Keitel is very satisfied with the collaboration: "The system house's hotline answered all our questions within minutes. We especially appreciate the pragmatic and solution-oriented approach of Coffee, so recently there was a problem with our license server; The coffee specialists came together with our IT department and found a solution. "The experience of the course participants was also positive when introducing the Composer, as the developer says:" The training quickly showed us the composer's extensive capabilities , That made our training much easier. "

With Coffee as a system house, the lighting manufacturer has been working together ever since Solidworks came into the house. Henning Keitel is very satisfied with the collaboration: "The system house's hotline answered all our questions within minutes. We especially appreciate the pragmatic and solution-oriented approach of Coffee, so recently there was a problem with our license server; The coffee specialists came together with our IT department and found a solution. "The experience of the course participants was also positive when introducing the Composer, as the developer says:" The training quickly showed us the composer's extensive capabilities , That made our training much easier. "

"We are a design-oriented company," concludes Raphael Eisenberg: "That's why shape and its visualization are very important to us. In addition, the quality is in the center, to which the heat simulation makes a very important contribution. Solidworks helps us to turn our principles 'Made for Industry' and 'Dedicated to the Future' into reality and to continue to be successful as a leading German lighting manufacturer. Coffee, in turn, makes sure that this tool runs smoothly and we can use it efficiently. We are very pleased with Dassault Systèmes' Solidworks and Coffee. "

The author Ralf Steck is a freelance journalist for CAD / CAM, mechanical engineering and IT in Friedrichshafen.

You might also be interested in...

3Dexperience World and Conference

Solidworks 2024 | CAD software by and for users

Dassault Systems | The 3DExperience Company

CAD automation creates freedom for the designer

Spacemouse compatibility with Solidworks Xdesign