for suppliers and OEMs

Product Solutions and trends for conventional vehicles, electric cars, autonomous driving with a focus on sustainable mobility

Image: Weride

for suppliers and OEMs

Product Solutions and trends for conventional vehicles, electric cars, autonomous driving with a focus on sustainable mobility

Image: Weride

Here you will find the latest developments and trends from the automotive industry Supplier industry for conventional automobiles, electric vehicles or autonomous driving for the R&D departments of Automotive industry like BMW, Volkswagen, Daimler, Ford, Porsche and many more. Find out about solutions and trends, especially in the field of passenger cars, for the sustainable mobility of automobiles.

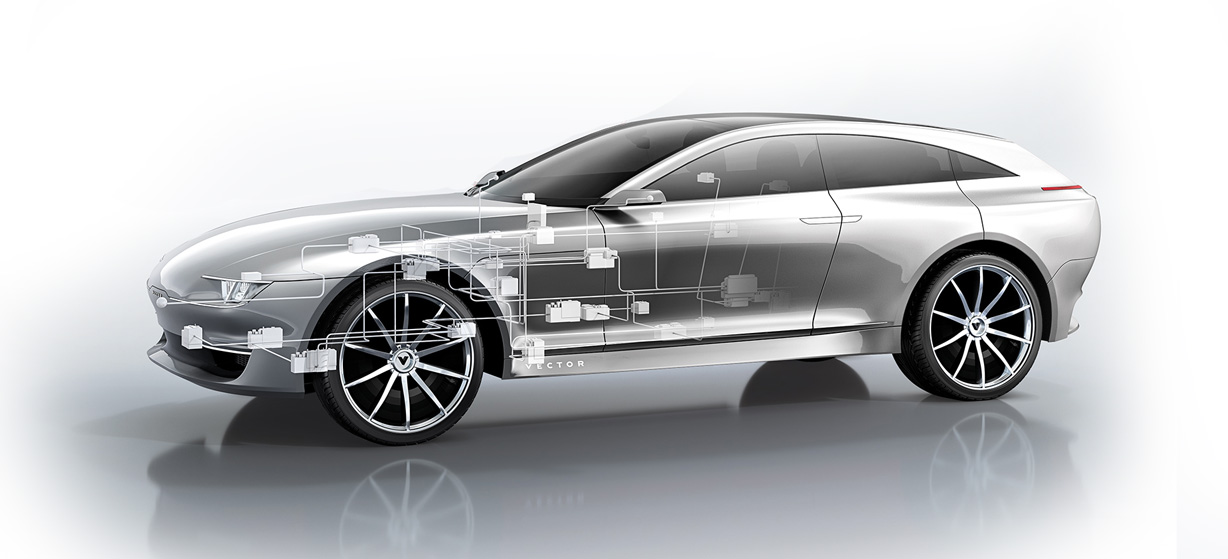

While dad used to lend a hand himself and quickly replace the spark plug, the move in has Electronics the automotive industry has since revolutionized. Automobile development has also changed fundamentally as a result. Almost nothing works without electronics and almost everything should be done electronically in the autonomous vehicle, including driving itself. It goes without saying that today's automobile engineers have a large amount of expertise in Digitalization, Communication, and have to bring electronics.

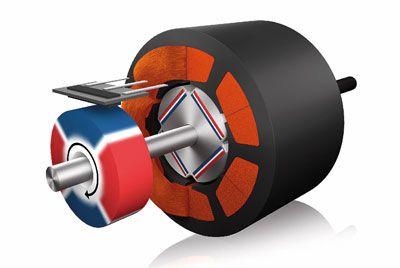

We report on supplier parts for the powertrain, drivetrain, chassis, body and interior, electronic components and groundbreaking innovations, including interfaces for communication, alternative drives, Materials and above all safety technology in cars.

15.01.2024/XNUMX/XNUMX | With the Kitorq DS Kistler the first Torque measurement system developed for vehicle axle shafts with wireless data transmission. The transmitter is located above the strain gauge sensor and can be attached to the drive shaft using an adapter. This means the unit can be easily removed, for example if you B. the Batteries change or charge or attach the transmitter to another vehicle.

15.01.2024/XNUMX/XNUMX | With the Kitorq DS Kistler the first Torque measurement system developed for vehicle axle shafts with wireless data transmission. The transmitter is located above the strain gauge sensor and can be attached to the drive shaft using an adapter. This means the unit can be easily removed, for example if you B. the Batteries change or charge or attach the transmitter to another vehicle.

Quick adjustments to the latest developments are particularly necessary in the automotive industry in order to stay at the forefront. The integration of Real-time data generation and management in all vehicle and parts production processes helps to overcome market and supply chain challenges. More about this from Lucas Majewski from Mitsubishi Electric in the videocast.

Quick adjustments to the latest developments are particularly necessary in the automotive industry in order to stay at the forefront. The integration of Real-time data generation and management in all vehicle and parts production processes helps to overcome market and supply chain challenges. More about this from Lucas Majewski from Mitsubishi Electric in the videocast.

Due to the ever-growing demand in the private sector, Schukat focuses its range of relays on electric vehicles and their charging infrastructure. The AZEV116, AZEV132 and AZEV140 series single pole relays from note are specially designed for use in charging cables designed in accordance with IEC 62752 for charging electric vehicles in charging mode 2.

Due to the ever-growing demand in the private sector, Schukat focuses its range of relays on electric vehicles and their charging infrastructure. The AZEV116, AZEV132 and AZEV140 series single pole relays from note are specially designed for use in charging cables designed in accordance with IEC 62752 for charging electric vehicles in charging mode 2.

July 26.07.2023, XNUMX | The demand for lithium-ion batteries (LIBs) is increasing rapidly. Anyone who can quickly produce large quantities of high-quality batteries in a recyclable, sustainable and cost-efficient way is at the forefront. Explained in the videocast “Lithium-ion batteries”. Claus Petersen, how digital technologies can help the LIB industry to generate a competitive advantage with data.

July 26.07.2023, XNUMX | The demand for lithium-ion batteries (LIBs) is increasing rapidly. Anyone who can quickly produce large quantities of high-quality batteries in a recyclable, sustainable and cost-efficient way is at the forefront. Explained in the videocast “Lithium-ion batteries”. Claus Petersen, how digital technologies can help the LIB industry to generate a competitive advantage with data.

The production of multi-joint hinges for spoiler kinematics and top can be expensive. With a Igus bearings An economical and technically superior design is possible from tribologically optimized plastic. The new Iglidur F300 is even electrically conductive and can calibrate itself and prevent corrosion using the cathodic dip painting (KTL) process.

The production of multi-joint hinges for spoiler kinematics and top can be expensive. With a Igus bearings An economical and technically superior design is possible from tribologically optimized plastic. The new Iglidur F300 is even electrically conductive and can calibrate itself and prevent corrosion using the cathodic dip painting (KTL) process.

Schmersal represents a new one Magnetic track sensor box for the position detection of electric monorails in intralogistics and Automotive industry before. So far, wear-free magnetic switches have been used here, where they monitor the speed and position of moving machine parts. Such electric monorail systems transport body parts. a. to the assembly workstations. The SSB-R can now do that too.

Schmersal represents a new one Magnetic track sensor box for the position detection of electric monorails in intralogistics and Automotive industry before. So far, wear-free magnetic switches have been used here, where they monitor the speed and position of moving machine parts. Such electric monorail systems transport body parts. a. to the assembly workstations. The SSB-R can now do that too.

Sumika Polymer Compounds Europe (SPC Europe) and Hexagon Manufacturing Intelligence are working together to digitize the performance of new sustainable thermoplastics (PP) for the automotive industry. Based on the new multiscale technology for material modeling of thermoplastics, engineers can develop recyclable components and thus reduce the carbon footprint of future vehicles.

Sumika Polymer Compounds Europe (SPC Europe) and Hexagon Manufacturing Intelligence are working together to digitize the performance of new sustainable thermoplastics (PP) for the automotive industry. Based on the new multiscale technology for material modeling of thermoplastics, engineers can develop recyclable components and thus reduce the carbon footprint of future vehicles.

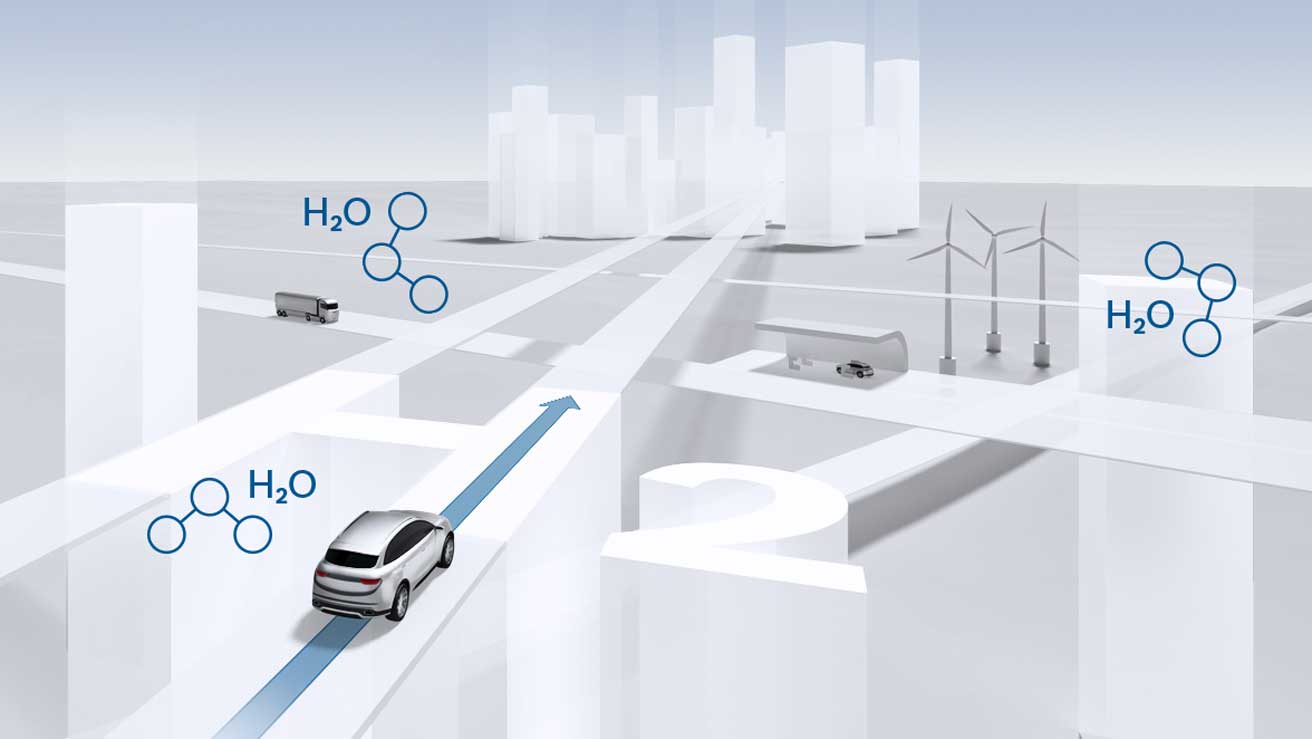

As the market for hydrogen mobility grows, with H2 as a promising energy source, the infrastructure for its provision is increasingly coming into focus. Resato Hydrogen Technology has along with Turck implemented an innovative concept for the locations of hydrogen stations: modular Hydrogen filling stations guarantee equipped with IP67-AtexI/O modules quick commissioning and high scalability.

Contents

Do companies invest in hydrogenInfrastructure, they attach great importance to scalability for future market requirements. That's why the Dutch hydrogen filling station manufacturer Resato Hydrogen Technology BV from Assen in the Netherlands relies on the decentralized concept of Turck's IP67 I/O module. It is the only one on the market that offers a comprehensive solution for modular systems for all signal types including safety, even in hazardous areas.

Do companies invest in hydrogenInfrastructure, they attach great importance to scalability for future market requirements. That's why the Dutch hydrogen filling station manufacturer Resato Hydrogen Technology BV from Assen in the Netherlands relies on the decentralized concept of Turck's IP67 I/O module. It is the only one on the market that offers a comprehensive solution for modular systems for all signal types including safety, even in hazardous areas.

Hydrogen is used as Energy sources in the future play an important role. In particular, trucks and buses will increasingly switch to H2 mobility. Hydrogen also seems to be establishing itself as an energy source for cars in the long term. Resato is one of the companies that is benefiting from this trend with its hydrogen filling stations.

The company's innovation lies in the High pressure technology. Resato has established itself in the waterjet cutting niche market since the early 90s. The engineers have also been using the know-how generated here in the development and construction of hydrogen filling stations since 2018. The company has already produced and put more than 45 hydrogen filling stations into operation across Europe - 9 of them in the Netherlands.

Hydrogen filling stations can obtain their fuel in two different ways:

Hydrogen filling stations can obtain their fuel in two different ways:

A hydrogen filling station is therefore much more complex than a carbon-based fuel filling station. The hydrogen filling station system must deliver the hydrogen in a series of cooling and compression steps necessary pressure bring. Bigger pressure in turn leads to increased temperatures. That's why the hydrogen has to be cooled down again and again.

The complexity of hydrogen filling stations lies in the steering. Resato has developed a patented algorithm for this that allows the fastest possible refueling depending on temperature and pressure. At the I/O level, the explosive H2 poses a particular challenge to the automation concept. The hydrogen requires an explosion protection concept and the installed components must have appropriate approvals.

In addition, the hydrogen filling station must be maximum maintenance because there are no staff on site who can make settings. Mainly temperature and pressure signals as well as switching signals from control valves are to be processed here. There are also safety-related signals from valves, emergency stop buttons and other safety sensors.

Hydrogen + fuel cell: components for energy generation

Hydrogen + fuel cell: components for energy generation

In the first H2 gas station version, Resator still has passive refueling systems I/O technology wired. Sensor and actuator signals were placed on passive distributors at the buffer storage and from there via multicoreLines led to the control. This reliably functioning solution was not very flexible as soon as the system was to be expanded to include additional buffer storage.

“It was electrically very complex to add a unit. We also had to completely redesign the software. So we decided to divide the whole system into modules so that we can control each module individually,” explains Remco Lagendijk, Electrical and Instrumentation Engineer at Resato, the beginning of the modular gas station concept.

The second generation of Resato hydrogen filling stations has a modular design. Buffer storage, cooling units and compressors can now be flexibly added and combined. To make it easier to supplement the aggregates, all signals on each aggregate must be in one data line converge.

The second generation of Resato hydrogen filling stations has a modular design. Buffer storage, cooling units and compressors can now be flexibly added and combined. To make it easier to supplement the aggregates, all signals on each aggregate must be in one data line converge.

The buffer storage requires an I/O solution for this Industrial Ethernet in the form of Profinet. Resato wanted that housing and save mechanical effort. That's why the developers looked IP67 I/O modules, which are temperature-resistant and suitable for outdoor use. However, the modules should also have approval for Atex Zone 2 and be suitable for connecting intrinsically safe signals from Zones 1 and 0. This requirement causes the automation engineer to sweat.

Looking for an automation partner who also supports this decentralized concept hazardous area can support, the Resato team has come to the Hannover Messe Gathered information and found it. The engineers saw many IP67 IO solutions at the exhibition stands.

But when it comes to the question of IP67 Atex approval Many providers had to adapt. “Except for Turck. They were able to offer us different solutions for IP67 in Atex zones. We understood that Turck is familiar with this and already has corresponding components on the market,” reports Mr. Lagendijk.

Resato and Turck then have one decentralized I/O concept developed for the buffer storage. “The support was really good. "They didn't just give us a few products and say, 'Good luck with that,' but we discussed the products intensively and thought through different options," explains Niels de Jong, engineer for research and development. "Turck even gave us the exact ones Cablestypes with the appropriate lengths recommended. Resato aims to be the global technology leader in the field of hydrogen filling stations. We need partners like Turck for this.”

Resato and Turck then have one decentralized I/O concept developed for the buffer storage. “The support was really good. "They didn't just give us a few products and say, 'Good luck with that,' but we discussed the products intensively and thought through different options," explains Niels de Jong, engineer for research and development. "Turck even gave us the exact ones Cablestypes with the appropriate lengths recommended. Resato aims to be the global technology leader in the field of hydrogen filling stations. We need partners like Turck for this.”

The I/O concept was designed to be completely decentralized – including the intrinsically safe ones Sensorsignals from Atex zones 0 and 1. With the IMC family, Turck has special Interface-Building blocks in IP67 in the portfolio. They are connected between the I/O device and the Ex sensor or actuator. They safely separate the circuits and transform the signal currents. Even the safety-related signals are distributed decentrally to the IP67 I/O module TBPN, which communicates with the safety controller via the Profisafe protocol.

“One of the advantages why we chose the Turck solution is the possibilities Offline testingsays Remcoo Lagendijk. “We used to have to test in production, then we dismantled everything and rewired everything on site at the customer’s site. Then of course we had to test again whether all inputs and outputs were connected correctly. Today we are testing our systems and letting everyone Plug connected to the remote I/O modules. We then only have to connect the power and data cables to the customer. This saves us a few days of commissioning time for the electrical work, which means we can work with fewer electrical engineers.”

Measurement technology ensures quality in hydrogen production

Measurement technology ensures quality in hydrogen production

He emphasizes this advantage modular concept: “Commissioning is a very critical phase. When errors occur here, it usually takes much longer to fix them than in production. Because in our own production, all the experts, the right tools and the necessary spare parts are immediately at hand, but not at the customer’s site.”

Resato thought the modular concept through to the end and also set up the control software in a modular manner. There is a module in the control software expandable, without having to rewrite the entire code. “It’s almost like copy-and-paste,” says Mr. Lagendijk.

Resato thought the modular concept through to the end and also set up the control software in a modular manner. There is a module in the control software expandable, without having to rewrite the entire code. “It’s almost like copy-and-paste,” says Mr. Lagendijk.

Based on the modular concept, Resato's hydrogen filling stations are very easy to set up scale. “If the customer wants to expand their storage and needs more buffer storage, then that’s not a problem for us – it’s very easy, especially from the electrical engineering side and the control,” adds Niels de Jong.

The demand for H2 filling stations is continuously increasing. Resato therefore expects production to be gradually transferred from the project organization to the Serial Production can be changed. The company is prepared for this with the modular H2 gas station concept and the modular I/O architecture. Because the concept enables entry into series production at any time. Individual modules such as buffer storage or compressors can be pre-produced in stock and then put together to suit the customer's specific needs. These economies of scale will reduce the costs and time-to-market of hydrogen filling stations.

In Germany there are currently over 80 public hydrogen filling stations, which are operated by H2 Mobility Germany. These stations supply 700 bar fuel cell vehicles, including cars and small commercial vehicles as well as waste collection vehicles. In addition, four further filling stations are being planned, constructed or commissioned. There are 350 hydrogen stations for buses and trucks that are refueled at 24 bar. A further 18 refueling options for 350 bar are currently being implemented.

For current and detailed information about the availability and locations of hydrogen filling stations in Germany, the H2.Live platform offers real-time data as well as an overview of all public hydrogen filling stations in Germany and Europe

The limited number of hydrogen filling stations is mainly due to the high investment and operating costs as well as the complex technological requirements. Building a dense, comprehensive network requires significant upfront investment in infrastructure, including the production, storage and distribution of hydrogen under high pressures.

In addition, the technical challenges, such as ensuring the safety and efficiency of the hydrogen supply, should not be underestimated. Since the demand for hydrogen vehicles is still low compared to conventional fuels or electric cars, investors are hesitant to invest in such a capital-intensive and technologically demanding network without having a clear idea of future market development and customer popularity. That's why the expansion of the nationwide hydrogen filling station network is so slow.

Bosch relies on the Hydrogen power. Electric Cars are important to the CO2emissions lower in traffic. But the question arises whether it is also economical, difficult Commercial Vehicles with a payload of 40 t over long distances using battery power? Find out below why Bosch is developing the technology further and which portfolio the global player offers for this:

To dem Hydrogen (H2) as an alternative fuel to achieve a breakthrough, we need attractive hydrogen cars and high-performance commercial vehicles that can be refueled in a nationwide filling station infrastructure. The structure of the corresponding hydrogen gas stations requires a lot Measurement Technology, so that safety when refueling with hydrogen is guaranteed. Wika offers the complex instrumentation for this, such as valves, temperature or pressure sensors.

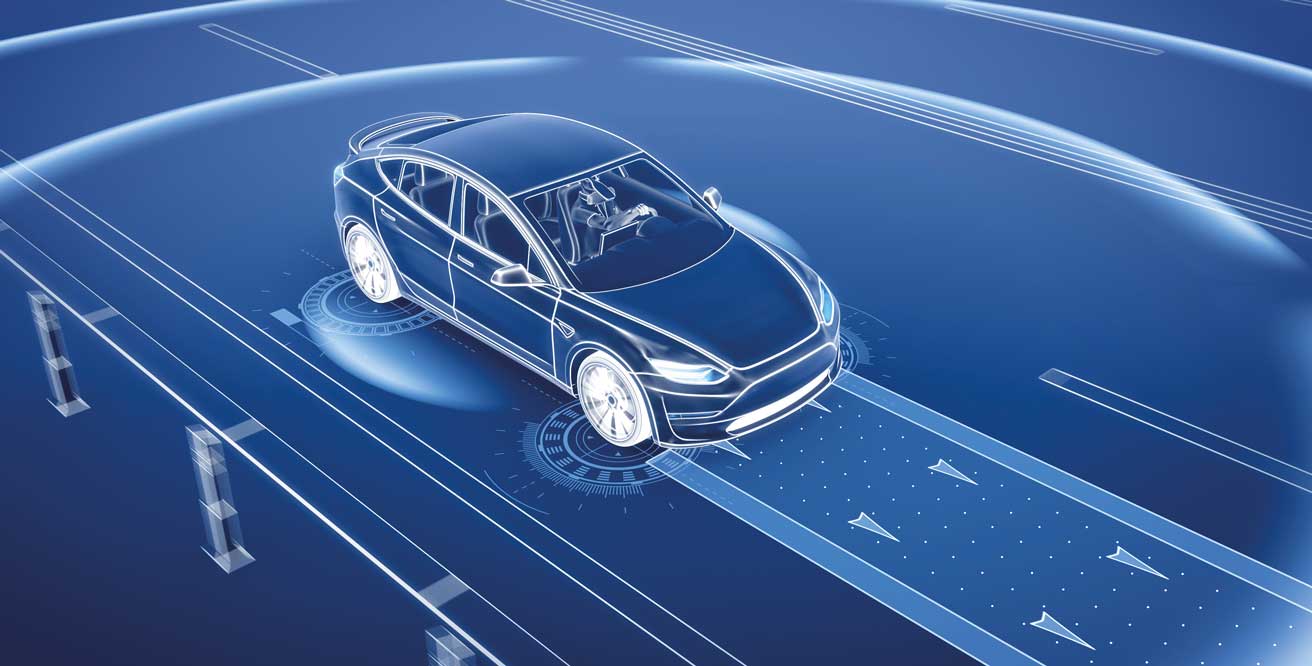

Modern Driving assistance systems use radar technology. There are many systems for adaptive speed control, support for changing lanes, avoiding collisions and recognizing pedestrians and cyclists. All pave the way to self-driving car. The Fraunhofer FEP now has one radar sensor developed in the Car headlights can be integrated.

BMI Test + Measurement extends its Cansasflex series for new highly insulated Measuring modules and Junction boxes for safe measurements in HV environments, especially to Electric Cars and Hybrid vehicles. The new four-channel measuring module "Hiso-HV4" is suitable for measuring high differential voltages up to 800 V. This enables, for example, HV voltages along the electrical line Powertrain capture as on Battery, charging converters, aggregates and distributors.

The pedal car Cit Kar by Johannes Kremer and Time is a revolutionary electric kettcar and fascinates the industry with an impressive range of 200 km. With a loading volume of up to 420 l and a payload of 300 kg, modern requirements for electric mobility are impressively met, especially in Germany. With the Cit-Kar, adults experience the joy of driving in a new and sustainable way.

Volkswagen sets new standards in the automotive industry. With a world Premiere The car manufacturer entered the race for the most fascinating new technical developments from car manufacturers at the CES 2024 electronics trade fair in Las Vegas: Volkswagen will be integrating from now on Chat GPT in current models. This pulls it Artificial intelligence into the automobile. These and more in the future VW news can be found in this article.

Which one E-car-Owner doesn't always want to have an efficient, fast, reliable and available way to charge their electric car? And because there are always new developments Charging plug and Charging cables for electric cars, we would like to introduce them to you here. Here you will find type 1 plugs, type 2 plugs, CCS plugs, the associated charging cables and one that is entered in the Guinness book, as well as other applications.

MS-Schramberg's magnetic sensors are used in various applications, particularly in the automotive industry. Here, magnetic field sensors ensure the smooth functioning of airbags, engine controls or anti-lock braking systems, for example. For the steering areaangle sensorThe company is also presenting measuring gears with integrated magnets for backlash-free gearing.

MS-Schramberg's magnetic sensors are used in various applications, particularly in the automotive industry. Here, magnetic field sensors ensure the smooth functioning of airbags, engine controls or anti-lock braking systems, for example. For the steering areaangle sensorThe company is also presenting measuring gears with integrated magnets for backlash-free gearing.

The GPS-supported "Adma" gyro system from Genesys was specially developed and built for vehicle dynamics and driver assistance measurements in the automotive sector. With the Automotive Dynamic Motion Analyzer (Adma), all movement states such as acceleration, speed, position, rotational speed, position and float angle of the vehicle can be recorded with high precision while moving.

The GPS-supported "Adma" gyro system from Genesys was specially developed and built for vehicle dynamics and driver assistance measurements in the automotive sector. With the Automotive Dynamic Motion Analyzer (Adma), all movement states such as acceleration, speed, position, rotational speed, position and float angle of the vehicle can be recorded with high precision while moving.

Mitsubishi Electrics Information Technology R&D Center in Japan has a new one sensor technology developed, which enables a highly precise recording of vehicle parameters even in thick fog or heavy rain. The technology is said to be a robust function of autonomous and assisted driving systems even in harsh weather conditions, under which the detection accuracy of conventional sensors decreases.

Mitsubishi Electrics Information Technology R&D Center in Japan has a new one sensor technology developed, which enables a highly precise recording of vehicle parameters even in thick fog or heavy rain. The technology is said to be a robust function of autonomous and assisted driving systems even in harsh weather conditions, under which the detection accuracy of conventional sensors decreases.