Since the beginning of 2017, the two PCB manufacturers from Baden-Württemberg, Würth Elektronik and Fela, have been researching the digitization of circuit board technology. The prototypes in July were already promising - in October both partners successfully delivered the first series orders in the respective pilot projects.

Since the beginning of 2017, the two PCB manufacturers from Baden-Württemberg, Würth Elektronik and Fela, have been researching the digitization of circuit board technology. The prototypes in July were already promising - in October both partners successfully delivered the first series orders in the respective pilot projects.

The company's "S.mask" technology pursues a paint and machinery-independent approach to applying a defined, functional surface via 3D printing. From the point of view of the two companies, this is the best starting point for gradually digitizing printed circuit board production and its processes.

The first material tests and investigations confirm an enormously improved precision and various possibilities for the user-specific definition of the mask. Both offset and the general tolerances can be significantly reduced.

Individual design of the surface

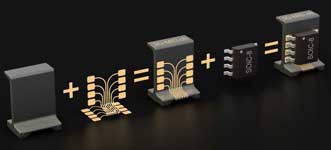

In particular, the individual design of the surface allows customer requests and special requirements with regard to z. B. to consider the dielectric strength. The S.mask system is the first and only technology in the industry to offer the possibility of applying not just one but several layers of a dielectric in a defined and targeted manner.

A special performance was observed in the first series of experiments on soldering processes. Thus, a significant improvement could be achieved in most previously known soldering and assembly problems. If these observations are confirmed in the early 2018 trials, this would bring enormous benefits. Concrete statements, the two partners already expect mid-2018.

3D MID component carrier protects point of sale terminals

3D MID component carrier protects point of sale terminals

Norbert Krütt, Managing Director of Fela in Villingen-Schwenningen, is very satisfied with the results achieved so far: "The digitization of printed circuit board technology represents a technological quantum leap. Functional surfaces or dielectrics are no longer distributed as generously as with a watering can, but used purposefully to realize advantages in the following processes, both in printed circuit board manufacturing and later in our customers. "

First pilot projects

In addition to advantages in precision and performance, the first pilot projects also show improvements in the area of protection (protection) of the printed circuit board. This is achieved on the one hand by the gentle application of the functional surface, on the other hand by a reduction in the amount and type of chemicals used.

The cooperation takes place on all levels: from the management to the research departments to joint communication. Andreas Gimmer, Managing Director of Würth Elektronik CBT in Schopfheim, comments: "Since the beginning of our partnership cooperation, it has been shown that the cooperation of our companies achieves manifold synergy effects. We expect economic success, but also realize that collaborative research and development is simply a pleasure. "