Online magazine for design and development

Here you will find everything that the designer needs for his design and the development engineer for his new development, from the draft to quality assurance in production, such as new products, their applications, new technologies or research results. Company reports as well as topics on technological and megatrends in all industrial sectors complete our range of industry news. Let's start with the news.

Company News

IFM will increase sales to over EUR 2023 billion in 1,4

IFM Electronic was able to increase sales again in the 2023 financial year. The preliminary consolidated financial statements show a new sales record with sales of over 1,4 billion euros and growth of 3%.

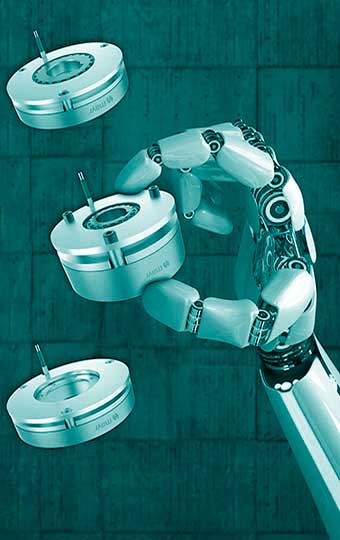

Jumo Campus for sensors and measurement technology

Jumo has designed further training courses with a view to the currently exciting topics being discussed in individual sectors and offers corresponding seminars as part of the Jumo Campus.

Schaeffler AG increases sales by 2023% in 5,8

Schaeffler AG's sales increased by 2023% to EUR 5,8 billion in 16,3. Currency-adjusted sales growth was 5,8 percent, which is within the forecast for the 2023 financial year.

New automotive production site in the USA

The Motion Technology Company Schaeffler will expand production in the USA with a new automotive production site. The new facility will be located in Dover, Ohio.

Ebm-Papst wants to sell industrial drive technology to Siemens

The Ebm-Papst Group has announced that it will sell its Industrial Drive Technology (IDT) division to Siemens AG. Both sides have signed a corresponding agreement.

Industry news for your design and development from the specialist areas

Drive Elements

New manufacturing technologies improve crown gear production

Welter Zahnrad has further developed its production processes for crown gears and can now produce them in quality 3967 according to DIN 5.

IPC

Ex-protected tablet with augmented reality qualities

Pepperl+Fuchs is expanding its Ecom “Tab-Ex” tablet series with a device based on the robust Samsung Galaxy Tabactive4 Pro.

Machine Elements

Door handle system displays machine statuses

Schmersal presents its new door handle system DHS. The door handle functions are combined with the display of machine states in the handles.

communication technology

Managed Bobcat Switch for rail vehicles

Belden's new Hirschmann BXP managed switch with speeds of up to 10 Gbit/s is compact, even more flexible and interoperable.

Industry news for your design and development from the branches

Mobile Machinery

Cylindrical roller bearings for heavy industrial gearboxes and construction machinery

Schaeffler is introducing new cylindrical roller bearings in which the service life has doubled and the load capacity has increased by 24%.

Automobile

IO module secures hydrogen filling stations from Resato

Resato Hydrogen Technology has implemented a modular and scalable concept for H2 filling stations with Turck and its IO modules.

food technology

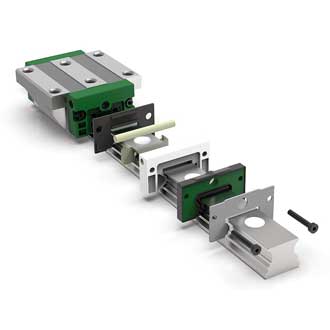

Lubrication and sealing-optimized linear guide

Schaeffler presents linear guides for food technology with optimized seals, wipers and long-term lubrication units.

Mobile Machinery

Flexible, customizable gateway for agricultural technology

IFM Electronic is presenting the Isobus Gateway at the Hannover Messe, which is designed for agricultural equipment and can be specifically adapted.

Industry fair news

Hannover Messe promotes energy for sustainable industry

As a networked industrial ecosystem, the exhibitors demonstrate how climate neutrality can be achieved through the use of electrification, digitalization and automation under the guiding theme of Energizing a sustainable Industry.

Control Fair 2024 | The industry is already looking forward to Stuttgart

Control 2024, the important international trade fair for quality assurance, will take place from April 23rd to 26th in Stuttgart. The trade fair places a particular focus on automation and digitalization.

SPS Nuremberg: Now in 16 halls!

The SPS – Smart Production Solutions from November 14th to 16.11th. 2023 will see significant growth in the trade fair compared to the previous year and is on the way to pre-Corona levels.

11.05.2022/XNUMX/XNUMX | With the Ultramid A3U44G6 DC OR (PA66 - GF30 FR) extended BASF the portfolio of flame-retardant engineering plastics in the manufacture of electric vehicles. The high technical requirements in electromobility require innovative solutions based on PA66. With the tried and tested Ultradur (PBT), the color stability can be largely guaranteed, especially in orange (RAL 2003), which is in high demand throughout the industry.

11.05.2022/XNUMX/XNUMX | With the Ultramid A3U44G6 DC OR (PA66 - GF30 FR) extended BASF the portfolio of flame-retardant engineering plastics in the manufacture of electric vehicles. The high technical requirements in electromobility require innovative solutions based on PA66. With the tried and tested Ultradur (PBT), the color stability can be largely guaranteed, especially in orange (RAL 2003), which is in high demand throughout the industry. 01.09.2021 | The thermoplastic Polyimide Aurum is a highly heat-resistant super-engineering plastic with high production efficiency in the injection molding sector. The thermoplastic challenges the conventional wisdom that polyimide performs very well but is difficult to process. flexible presents the PI portfolio as a distributor for PI Meldin from Saint-Gobain.

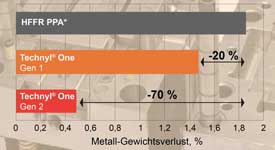

01.09.2021 | The thermoplastic Polyimide Aurum is a highly heat-resistant super-engineering plastic with high production efficiency in the injection molding sector. The thermoplastic challenges the conventional wisdom that polyimide performs very well but is difficult to process. flexible presents the PI portfolio as a distributor for PI Meldin from Saint-Gobain. 15.06.2020/XNUMX/XNUMX | The halogen-free, flame-retardant (HFFR) Technyl One Polyamide from Domo (Distribution: Ultrapolymers) enable very long tool life in the second generation. The corrosiveness of the polyamides is considerably lower than that of comparable types. The HFFR polyamides enable particularly long service lives

15.06.2020/XNUMX/XNUMX | The halogen-free, flame-retardant (HFFR) Technyl One Polyamide from Domo (Distribution: Ultrapolymers) enable very long tool life in the second generation. The corrosiveness of the polyamides is considerably lower than that of comparable types. The HFFR polyamides enable particularly long service lives  25.09.2019/1810/XNUMX | "Bruggolen TP-PXNUMX" by Bruggemann allows for the first time a significant improvement of the often critical Flow properties of polyphthalamides (PPA, such as PA6T, PA6T/6I, PA6T/6.6 etc.) while maintaining the mechanical property profile. Compounders and injection molders can thus significantly expand the processing window and combine high cost efficiency with application-specific optimization.

25.09.2019/1810/XNUMX | "Bruggolen TP-PXNUMX" by Bruggemann allows for the first time a significant improvement of the often critical Flow properties of polyphthalamides (PPA, such as PA6T, PA6T/6I, PA6T/6.6 etc.) while maintaining the mechanical property profile. Compounders and injection molders can thus significantly expand the processing window and combine high cost efficiency with application-specific optimization. 12.03.2019/XNUMX/XNUMX | In close cooperation with Joma Polytec and the Daimler AG subsidiary Mercedes Benz Fuel Cell has succeeded in making some components of the fuel cell system from the technical plastic "Ultramid" from BASF to manufacture. It is used as standard in the new "Mercedes GLC F-Cell", which is equipped with a combination of fuel cell and rechargeable

12.03.2019/XNUMX/XNUMX | In close cooperation with Joma Polytec and the Daimler AG subsidiary Mercedes Benz Fuel Cell has succeeded in making some components of the fuel cell system from the technical plastic "Ultramid" from BASF to manufacture. It is used as standard in the new "Mercedes GLC F-Cell", which is equipped with a combination of fuel cell and rechargeable  19.09.2016/XNUMX/XNUMX | The use of

19.09.2016/XNUMX/XNUMX | The use of  12.10.2016/XNUMX/XNUMX | the BASF responds to this Further development of engine concepts with a coordinated portfolio of polyamide PA6 and PA66 types that meet the increased demands on the materials used, their mechanical properties and temperature resistance. Depending on the base polymer and stabilization system, the thermoplastics are resistant to heat aging up to 220°C and have excellent burst pressure and

12.10.2016/XNUMX/XNUMX | the BASF responds to this Further development of engine concepts with a coordinated portfolio of polyamide PA6 and PA66 types that meet the increased demands on the materials used, their mechanical properties and temperature resistance. Depending on the base polymer and stabilization system, the thermoplastics are resistant to heat aging up to 220°C and have excellent burst pressure and  14.01.2014 | with PP (polypropylene) closes German Rep now fills an important gap in the supply of 3D printer consumables. This means that plates, cups or other containers for

14.01.2014 | with PP (polypropylene) closes German Rep now fills an important gap in the supply of 3D printer consumables. This means that plates, cups or other containers for