Professor Wilhelm Hannibal and his students from the South Westphalia University of Applied Sciences have an ambitious goal: They want to optimize oil pumps so that they help reduce the fuel consumption of combustion engines. While they carried out numerous tests, a test stand caused unwanted vibrations. PLM air suspension elements from ACE shock absorbers ensured calm in several places.

The Automotive degree program of the University of Applied Sciences South Westphalia imparts a broad-based, application-related, technical education for the automotive industry at the Iserlohn location on a scientific basis. The curriculum is specifically geared to the automotive supply industry. How close the applications of the young academics are to the practice can be seen in the field of the development of energy-saving drive systems.

The Automotive degree program of the University of Applied Sciences South Westphalia imparts a broad-based, application-related, technical education for the automotive industry at the Iserlohn location on a scientific basis. The curriculum is specifically geared to the automotive supply industry. How close the applications of the young academics are to the practice can be seen in the field of the development of energy-saving drive systems.

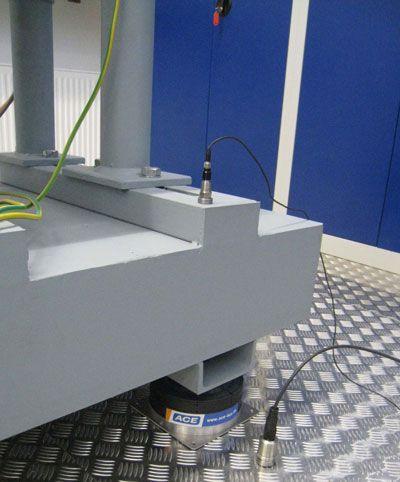

According to Sebastian Schütte, a member of the scientific staff of Prof. Hannibal, an important key in the engine oil pump is: "In the engine designs of earlier times, oil pumps always operated under full load, today they are regulated units. And if they can be used at a reduced flow rate, it is also possible to reduce their power consumption. "In order to approximate the optimum control state, it was necessary to record characteristic curves of the oil pumps and compare different control strategies. For this purpose, the team of the Automotive degree program built their own test bench. The overall design, with a length of 2500 mm and a width of 900 mm, came to a weight that equals that of a passenger car with 1500 kg.

Transmit vibrations in the room to another test station

One located on the test setup DC motor drives the pumps with 300 to 7000 min-1 on. "It was clear to us from the beginning that this speed spectrum was sufficient to make the design vibrate and that we had to take countermeasures to get reasonable measurement results," says Sebastian Schütte. Because besides the tests of hydraulic, volumetric and mechanical efficiencies for checking and optimizing flow behavior as well as for preventing leaks and reducing friction, the control technology is also under scrutiny and thus the question of which control technology works most effectively?

One located on the test setup DC motor drives the pumps with 300 to 7000 min-1 on. "It was clear to us from the beginning that this speed spectrum was sufficient to make the design vibrate and that we had to take countermeasures to get reasonable measurement results," says Sebastian Schütte. Because besides the tests of hydraulic, volumetric and mechanical efficiencies for checking and optimizing flow behavior as well as for preventing leaks and reducing friction, the control technology is also under scrutiny and thus the question of which control technology works most effectively?

For this reason, the test bench was placed on six rubber-metal insulators. These made for a reduction of the vibrations, but: "That had to go even better," Schütte sums it up. Especially since the vibrations were even sufficient to affect another test station in the same room also.

From theory directly to practice

The damping specialist is not only the world leader in the field of industrial and miniature shock absorbers, but has also earned an excellent reputation within a few years in vibration technology, including the elimination of unwanted vibrations. In addition, the company provides free corporate training over and over again and is also present at universities by being available to the technical faculties for demonstration and lectures from industry.

The damping specialist is not only the world leader in the field of industrial and miniature shock absorbers, but has also earned an excellent reputation within a few years in vibration technology, including the elimination of unwanted vibrations. In addition, the company provides free corporate training over and over again and is also present at universities by being available to the technical faculties for demonstration and lectures from industry.

It therefore made sense for Sebastian Schütte to contact the ACE employee responsible for lectures in the field of training, Jörg Brinkmann: “We heard from him about the 'Aceolator' series. Behind the name Aceolator there are a wide variety of products that are recommended as a solution to a wide variety of problems in reducing noise or eliminating disruptive vibrations. In addition to rubber-metal isolators, vibration isolating plates and low-frequency air suspension elements are also part of the Langenfelder portfolio.

DC motor as an all-round talent for countless applications

DC motor as an all-round talent for countless applications

The latter were to replace the solutions previously used at the Fachhochschule Südwestfalen. But before that happened, Jörg Brinkmann, together with his colleague Dieter Wohlschlegel, Engineering Manager at ACE, and the technical consultant Gregor Jandt, paid a visit to the academic team in Iserlohn to make an actual survey. For this the three drew a company-own measuring case and an external measuring sensor, which was connected to a Tablet PC. Based on the determined values, Dieter Wohlschlegel then made a design for so-called PLM air spring elements in a next step.

Comprehensive portfolio for vibration and vibration isolation

Like all air spring elements, the PLM1 pneumatic air spring elements used from the Aceolator series are located in the low-frequency range and are used when high-performance machines, measuring tables or test equipment have to be perfectly isolated.

Like all air spring elements, the PLM1 pneumatic air spring elements used from the Aceolator series are located in the low-frequency range and are used when high-performance machines, measuring tables or test equipment have to be perfectly isolated.

Depending on the degree of vibration and the environment, there are three different product series available, consisting of low-frequency air spring elements, rubber-metal isolators and vibration-isolating plates. Designers can use it to master almost all challenges in the field of vibration technology and vibration isolation. According to the manufacturer, this also applies to machines that are to be protected later.

Due to their internal air chamber, these low-frequency elements offer a significant insulating effect from a frequency of 5 Hz upwards. The natural frequency is 3 Hz in an optimally loaded state. This is achieved when the maximum load on the individual air spring elements is exhausted as much as possible. For applications such as that at the South Westphalia University of Applied Sciences, ACE has pneumatic air suspension elements with automatic level control valves for height control.

In these cases, each main isolator has an attached control valve that acts as a load feeler and position sensor. Any number of parallel air springs can be added to increase the load capacity of the overall system. This enables the manufacturer to expand the use cases even further. In addition to use on test benches, the air springs are particularly suitable for ensuring very good decoupling of disruptive vibrations under structures with measuring systems. They also insulate, for example, high-speed presses or all types of production systems from vibrations.

Both test tables are working properly now

The PLM are equipped with a vulcanized threaded insert, which means that the air springs can be pressurized with compressed air either via a standard tire valve or a pneumatic screw connection. Special connections are not necessary with these easy-to-level, innovative elements. In the event that level control valves are not used, a regulator control unit can also be provided to regulate the pressure and height of the interconnected air springs.

Small maintenance-free plain bearings made of plastic travel around the world

Small maintenance-free plain bearings made of plastic travel around the world

However, this was not necessary in Iserlohn to achieve the desired result. “Both test tables are now working perfectly. This means that we can now continue our work even better than before,” states Sebastian Schütte with satisfaction. An important step on the way to even more energy-efficient motors has thus been taken for Professor Wilhelm Hannibal's team at the South Westphalia University of Applied Sciences.