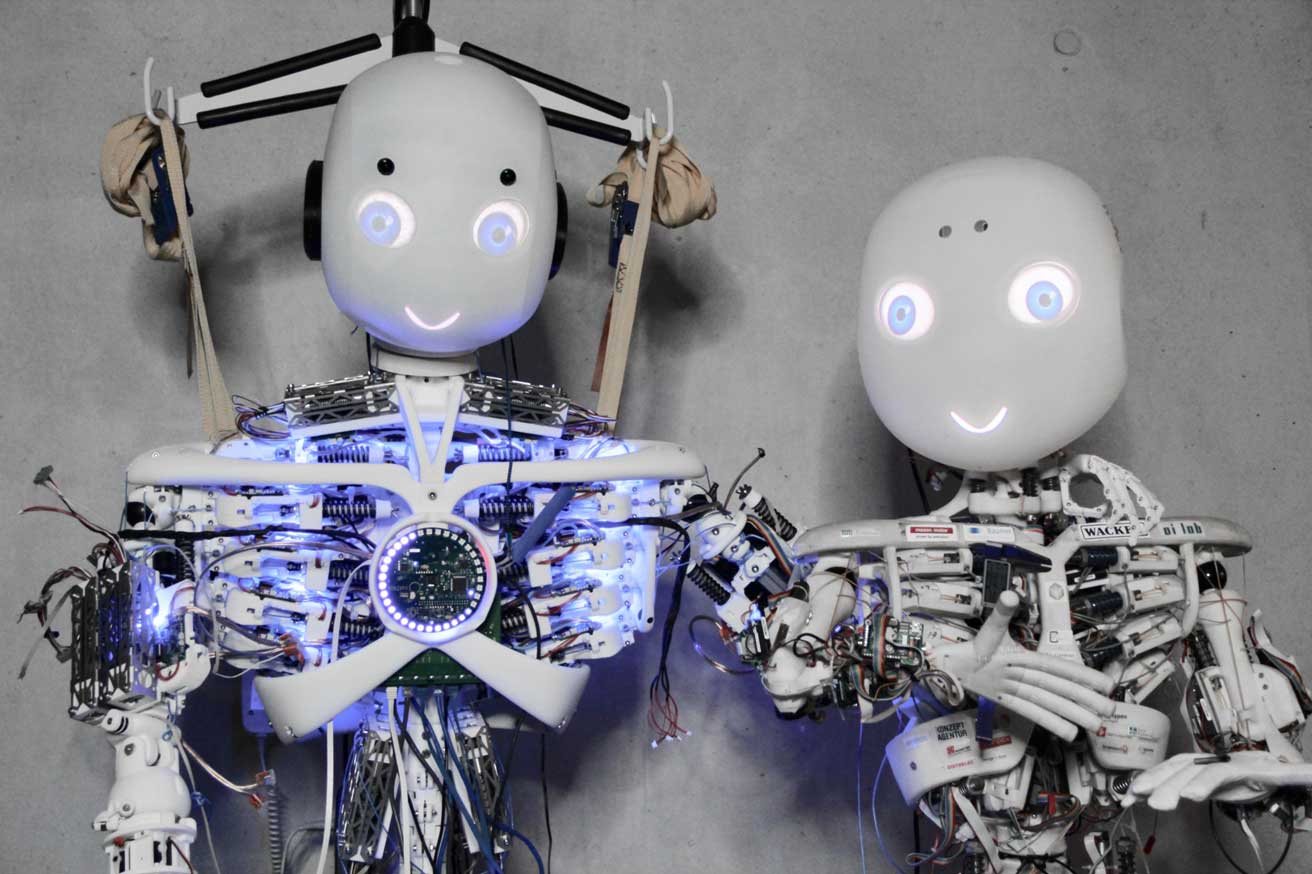

Of the highest achievements of human evolution Robot still far away at this point. A development team of the non-profit project Roboy from Munich, however, has set itself the goal of developing a robot that should come as close as possible to the human in its entire appearance. Roboy 2.0 was developed with the collaborative software "Fusion 360" by Autodesk

Contents

- Interdisciplinary teams develop complex models

- 3D printing for rapid development steps

- Future music with practical relevance in many areas

Interdisciplinary teams develop complex models

The human body is a masterpiece from a robot's perspective: agile, dynamic, flexible and yet strong. Wounds heal themselves and it is completely silent when used. A skeleton perfected over millions of years allows him to walk upright and the complex interaction of countless muscles, tendons and joints allows him to work skillfully and delicately with his hands.

The human body is a masterpiece from a robot's perspective: agile, dynamic, flexible and yet strong. Wounds heal themselves and it is completely silent when used. A skeleton perfected over millions of years allows him to walk upright and the complex interaction of countless muscles, tendons and joints allows him to work skillfully and delicately with his hands.

Roboy 2.0 (pronounced Roboy two-oh) is an interdisciplinary basic research project of gigantic proportions and a fairly ambitious development plan. “Our goal is to design a humanoid robot that is just as functional as the human body,” explains Rafael Hostettler, head of the Roboy project. “Not only should it be able to move like a human, but it should also be able to see, hear and interact like us.”

That's why the team brings together over 100 students, doctoral students and graduates Technical University of Munich Experts from a wide range of specialist areas. They have been working together with a network of scientists around the world on the development of the humanoid robot for years.

The Royal Institute of Technology in Stockholm (neuroprosthetics), the Chinese University of Hong Kong (algorithms for controlling the robot), Oxford University (loading artificial tendons during their growth) and of course the TUM (Robotic & real-time systems, product development methods) are, for example, permanent cooperation partners.

At the current stage of development, Roboy can already ride on a bike pedal, recognize people and have simple conversations. He should be able to play the xylophone as early as fall - a particularly complex task for robots due to the dynamics required - and be able to sell ice cream next year. By 2020 it should be able to carry out basic medical diagnostics. All research is open source and creates foundations in robotics, artificial intelligence and audiovisual data processing.

A few grams less hand for a lighter hip

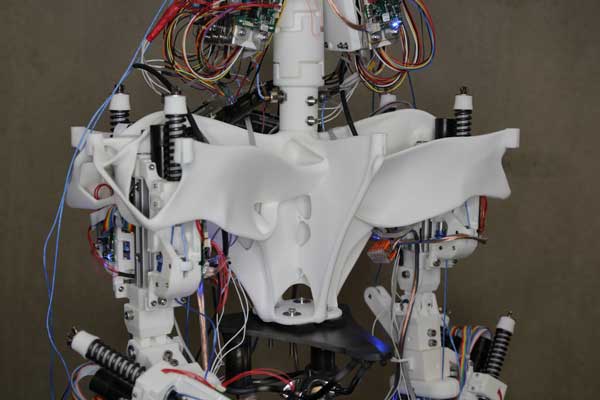

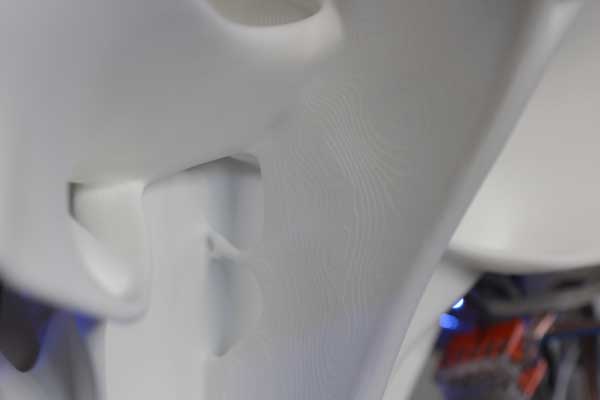

The structure, weight and nature of the bone-like components also play an important role in this context. Imaging the human body mechanically is very difficult. This is how the engineers use methods like 3D Print, generative design and other state-of-the-art technological processes to create bones, muscles and tendons instead of simply replacing joints with motors, as is usually the case in robot construction.

The structure, weight and nature of the bone-like components also play an important role in this context. Imaging the human body mechanically is very difficult. This is how the engineers use methods like 3D Print, generative design and other state-of-the-art technological processes to create bones, muscles and tendons instead of simply replacing joints with motors, as is usually the case in robot construction.

The team uses it to develop Roboy 2.0 Autodesk Fusion 360 with generative design. In the so-called generative design process, this allows the scientists to significantly reduce the weight of important components of the robot while maintaining stability at the same time.

“If we save a few grams of weight in the hand, the forces that the hip has to withstand are reduced and we can make it lighter accordingly,” says Hostettler. “This means we can save weight on all other components, which makes Roboy even more agile.” Not an end in itself, because Roboy is intended to be long-term running independently learn. For the first steps, a light yet stable footing is mandatory.

“If we save a few grams of weight in the hand, the forces that the hip has to withstand are reduced and we can make it lighter accordingly,” says Hostettler. “This means we can save weight on all other components, which makes Roboy even more agile.” Not an end in itself, because Roboy is intended to be long-term running independently learn. For the first steps, a light yet stable footing is mandatory.

At Roboy 2.0. Generative design is currently in use Hip applied. Thanks to calculations in the cloud, the team only needed three days to develop the first prototype version. The next parts to be reworked are the head shell and the motor housings. In the medium term, even the spine with the moving elements of the robot should be optimized.

Agile collaboration as the key to success

Autodesk Fusion 360 not only serves as a design and working platform for researchers, but also enables them to collaborate across locations and national borders. The tool was created as a agile working environment developed that allows researchers to work in extremely short development cycles, so-called sprints. Old versions can be restored quickly or two options can be checked in parallel. Agile methods help by establishing hierarchy-free communication and allowing quick interaction with prototypes. The individual project groups can react very quickly to changes.

Adaptive exoskeleton for the stroke patient

Adaptive exoskeleton for the stroke patient

3D printing for rapid development steps

Another advantage of using Autodesk Fusion 360 is the direct suitability of the designs created in it for 3D printing processes. Files created in Fusion do not have to undergo lengthy preparation for printing; instead, they can be converted directly into 3D printed objects without any compilation effort. At Roboy 2.0 are almost all parts laser sintered, i.e. 3D printed in plastic-like materials.

Another advantage of using Autodesk Fusion 360 is the direct suitability of the designs created in it for 3D printing processes. Files created in Fusion do not have to undergo lengthy preparation for printing; instead, they can be converted directly into 3D printed objects without any compilation effort. At Roboy 2.0 are almost all parts laser sintered, i.e. 3D printed in plastic-like materials.

“Classic milled parts require a delivery time of around 6 to 8 weeks, an eternity in agile product development,” explained Hostettler. “During this period, we have already developed 3 to 4 new product variants.” Another advantage: The geometric freedom of 3D printing allows the team to design components as they should be, not as they have to be created due to manufacturing obstacles. The tool-free production also saves time and costs.

Future music with practical relevance in many areas

Roboy 2.0 is a fascinating example of human evolutionary spirit. Even if the robot itself today is primarily used for basic research, the knowledge gained during development is already having an impact on numerous other areas. The project has application in human-robot collaboration. The project is also invaluable for the development of innovative prostheses or exoskeletons. With the help of the findings gained in the Roboy 2.0 project, neuroscientists understand better how the human body interacts with... 600 muscles coordinated.