Conducting hot gases and vapors safely at up to 850 ° C - for many manufacturers of components for process industry provides the austenitic stainless steel 1.4550 / 347H the solution. To meet the increasing demand, has Ugitech from the Schmolz + Bickenbach Group has expanded its broad stainless steel portfolio to include the UGI 4550, making it one of only three suppliers in Europe.

Steam lines, superheater tubes and exhaust systems in reciprocating pistonsmotors and gas turbines are classic areas of application for the UGI 4550. The steel grade refined with niobium is a requirement-based solution for temperature ranges between 425 ° and 850 ° C. Unlike most austenitic Materials the UGI 4550 is protected against structural precipitations in the form of chromium carbides and thus against intergranular corrosion.

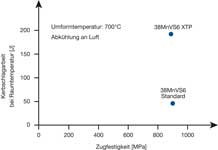

50 percent higher impact energy of high-alloy steel

50 percent higher impact energy of high-alloy steel

Stainless steel is ideal for components where post-welding treatment of the material is not possible, such as expansion joints and equipment for chemical processing at high temperatures. The UGI 4550 also offers a good formability at room temperature and is very easy to weld. A hot crack formation after welding is excluded. Furthermore, good creep resistance (resilience to temperature-dependent deformation) and resistance to atmospheric corrosion and oxidation at high temperatures increase process reliability.

Annealed or cold drawn austenitic steel

The wide range of dimensions ranges from Steel bars with a diameter of 130 mm up to ultrafine wires with a diameter of 16 µm. The steel product is offered annealed or cold drawn depending on the required mechanical properties. The minimum order quantity is only 1 t for drawn steel bars and even lower for drawn wires. Equipping the steelworks with 40 t melting furnaces enables fast delivery.