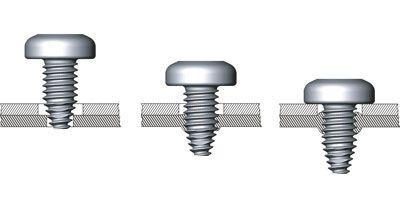

Years ago, commercially available self-tapping screws were often used for sheet metal thicknesses of 1 mm and more, but this is no longer possible today with increasing reduction in sheet metal thickness due to the exhaustion of potential cost savings. In particular, the process-reliable assembly of pre-perforated, thin sheet metal turns out to be by no means trivial in the area of self-tapping screw connections. Ejot knows how to do it and presents the "Sheettracs" as the solution.

Since tapping screws compounds of the thickness of the components to be connected at least equal to the slope of the tapping screw used, it must sheet thickness reduction in the modification in many areas quickly reach their limits. In reality, therefore a multiple repeated assembly is virtually impossible, since in some cases only one thread is in Einschraubblech engaged. Therefore, the thin sheet metal screws so-called have prevailed in the market in recent years. These screws are threaded ° and are usually carried out with a conical tip a metric 60. The advantage of the metric thread is the smaller thread pitch compared with self-tapping screws, allowing more screw thread is for engagement.

Efficient from direct screwing to screw drive

Efficient from direct screwing to screw drive

Weakness nut thread

Mostly, however, represents the shaped nut thread - represent the actual weak point of connection The potential of this approach point have recognized the connection technology experts early on and developed a special thin-tapping screw for controlled assembly in pre-holed thin-sheet - and not screw.. The "SHEETtracs" screw has a 45 ° (30 ° / 15 °) asymmetrical flank angle to it - due to the smaller displacement of material - to produce a more stable nut thread in Einschraubblech. This allows the torque level of the screw is increased and multiple repeated assembly allows.

Mostly, however, represents the shaped nut thread - represent the actual weak point of connection The potential of this approach point have recognized the connection technology experts early on and developed a special thin-tapping screw for controlled assembly in pre-holed thin-sheet - and not screw.. The "SHEETtracs" screw has a 45 ° (30 ° / 15 °) asymmetrical flank angle to it - due to the smaller displacement of material - to produce a more stable nut thread in Einschraubblech. This allows the torque level of the screw is increased and multiple repeated assembly allows.

In the lower conical portion of the screw, the flank angle rotates, thereby the resulting passage forms in the screwing. The non-circular thread forming zone provides a simple centered attaching the increased thread areas allow safe penetration into the sheet metal material. In contrast to non-circular thread geometry of the circular cross-section achieves a higher flank coverage in the upper, load-bearing thread. The metric slope of Sheetracs ensures interchangeability with metric screws, for example, in case of repairs.

lightweight included

This connecting element also supports the implementation of individual lightweight construction strategies, not only in the automotive sector. Thus, when using these screws, such as household products of "white goods", the sheet thickness of the housing walls are reduced - a not insignificant factor for the weight, but also for cost optimization in this product category.

You might also be interested in...

screw connection | Well connected!

Cochlear Implant | I hear you well!