epoxy resin adhesive, also epoxy glue, is called construction adhesive used, which is particularly strong and resistant even at high temperatures. The connections of the 1K or 2K adhesives are vibration-resistant, vibration-resistant and impact-resistant. the constructor is very flexible with an epoxy resin adhesive and can also be different Materials glue together. Here we present the new epoxy resin adhesives:

Contents

- Epoxy adhesive for high temperature applications

- Structural adhesive with quadruple temperature resistance

- Structural epoxy resin adhesive in a material mix

- Fast structural adhesive for lightweight construction in aircraft interiors

- Thin epoxy resin adhesive for bonding and potting

Epoxy adhesive for high temperature applications

17.01.2023/XNUMX/XNUMX | Designed for use in Electrical Engineering, heating technology and Metal Processing are the two-component casting compounds and adhesives from Kager. Epoxy Adhesive Type 4439 is an amber-colored, two-component (2K) epoxy resin adhesive suitable for bonding up to 150°C and potting up to 250°C. After mixing, the epoxy adhesive has a viscosity of 1500 mPas.

17.01.2023/XNUMX/XNUMX | Designed for use in Electrical Engineering, heating technology and Metal Processing are the two-component casting compounds and adhesives from Kager. Epoxy Adhesive Type 4439 is an amber-colored, two-component (2K) epoxy resin adhesive suitable for bonding up to 150°C and potting up to 250°C. After mixing, the epoxy adhesive has a viscosity of 1500 mPas.

After application and drying, the compound has a high mechanical strength. The epoxy resin adhesive is typically used for bonding and potting metal and Glass as well as technical Plastic and ceramics. After curing, the Epoxy Type 4439 proves to be resistant to diesel oil, motor oil, hydraulic oil and fuel oil as well as petrol, acetone, ammonia, glycerine, glycol, xylene and toluene. The epoxy resin adhesive is also resistant to diluted acids and alkalis.

Due to these properties and its compatibility with technical ceramics, this epoxy resin adhesive is often used in combination with the Casting compounds Kager Ceramacast 586 and Ceramacast 645N are used. Adhesives and potting compounds are also available in small quantities.

Structural adhesive with quadruple temperature resistance

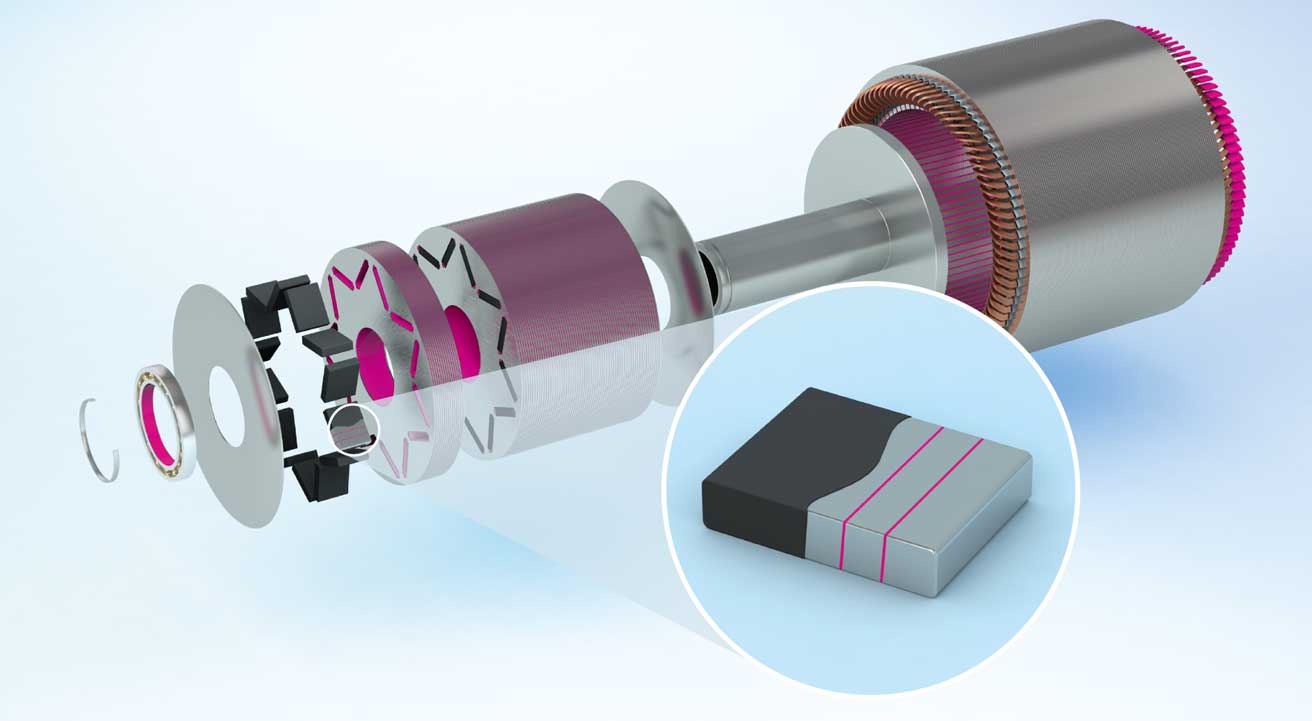

12.04.2021 | Delo introduces an adhesive with exceptionally high temperature resistance. The "Monopox HT2999" achieves strengths of 180 MPa at temperatures of 20 °C. That is four times as much as the previous adhesive was able to do. The epoxy adhesive was developed especially for mechanical engineering and the Automotive industry. High-temperature-resistant adhesives are mainly used for connections in the power Electronics and in electric motors asked. However, many adhesives show a significant drop in performance at temperatures above 150 °C. The structural adhesive Monopox HT2999 was therefore designed for this temperature range.

The adhesive is particularly optimized for the Bonding of magnets in electric motors. The compressive shear strength of magnetic material (NdFeB) bonds is 180 MPa at 10.000 °C even after 20 hours of storage. The connection is thermally stable over the long term. The maximum operating temperature for electric motors is often 180 °C because the powerful rare earth magnets demagnetize at higher temperatures. If the application requires resistance to even higher temperatures, the structural adhesive can even be used up to 220 °C.

Another important property of the adhesive is that electrical insulation. It minimizes eddy currents in electric motors, thus reducing heat generation and enabling higher motor performance. The epoxy resin-based adhesive is also equipped with integrated spacers. They automatically ensure a uniform and very thin adhesive gap of 50 µm for segmented magnets. This allows more magnet material to be used, which contributes to motor efficiency.

The epoxy is one-component, gray and pasty. Curing at 150 °C in a convection oven only takes 10 minutes. Compared to previous high-temperature adhesives with a curing time of 30 to 40 minutes at 150 °C, the adhesive saves time and energy.

Structural epoxy resin adhesive in a material mix

18.08.2020 | 3M has expanded its range of Scotch-Weld 2K epoxy-based structural adhesives with two adhesives, DP 100 Plus and DP 420 NS. Both are very suitable for joining different materials. Their connections offer high structural strength and are very resilient. The epoxy adhesives easily join different materials such as metal, plastic, glass, ceramics and wood. The connections are shear resistant, peel resistant and impact resistant.

18.08.2020 | 3M has expanded its range of Scotch-Weld 2K epoxy-based structural adhesives with two adhesives, DP 100 Plus and DP 420 NS. Both are very suitable for joining different materials. Their connections offer high structural strength and are very resilient. The epoxy adhesives easily join different materials such as metal, plastic, glass, ceramics and wood. The connections are shear resistant, peel resistant and impact resistant.

The 3M Scotch Weld 2K construction adhesive epoxy based DP 100 Plus is flexible. Thanks to the very short processing time of just 3 minutes at room temperature, the adhesive is suitable for fast processes. After only 20 minutes it reaches hand strength. When hardened, it is flexible and can be exposed to strong dynamic loads and vibrations. The transparent adhesive also has good thermal properties and is suitable for use in the automotive industry and special vehicle construction, metalworking and sporting goods production or jewelry production.

The 2K construction adhesive 3M Scotch-Weld DP 420 NS is impact-resistant and also based on epoxy resin. The processing time at room temperature is 15 to 20 minutes, which is enough time to position the parts to be joined exactly. After a further 40 minutes the adhesive reaches handling strength. Even under challenging conditions, the connections are as strong as possible, have good resistance to aging, weather and fatigue. The DP 420 NS is suitable for joining heavy loads in metallurgy such as for the joint assembly. It meets the requirements of UL 94 HB. It is available in cartridges and in barrels.

The two construction adhesives are dosed, mixed and applied in just one operation. The static mixing nozzle guarantees perfect mixing and thus adhesive bonds consistently high quality.

Fast structural adhesive for lightweight construction in aircraft interiors

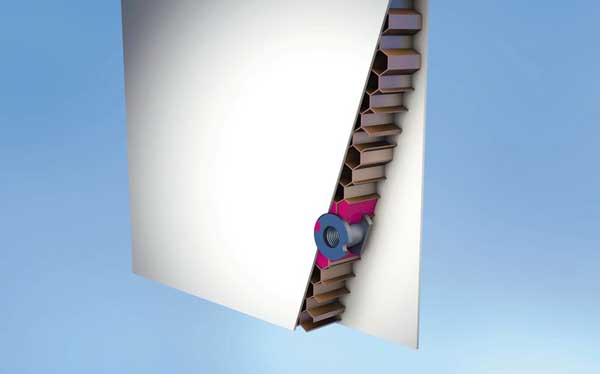

18.12.2018 | With the new flame-retardant structural adhesive "Duopox AB8162". Delo for faster processes in the production of commercial aircraft. The two-component epoxy resin adhesive was specially developed for lightweight structural connections in aircraft interiors. Attention was paid to a rapid build-up of strength.

18.12.2018 | With the new flame-retardant structural adhesive "Duopox AB8162". Delo for faster processes in the production of commercial aircraft. The two-component epoxy resin adhesive was specially developed for lightweight structural connections in aircraft interiors. Attention was paid to a rapid build-up of strength.

Duopox AB8162 cures at room temperature but is for temperature accelerated curing optimized. At a temperature of 60 °C, a curing time of only 15 minutes is required to achieve functional strength of ≥10 MPa. This means that further processing of the components is already possible after this short time.

The adhesive is used universally and is used, among other things, as a coating or when gluing inserts Fasteners Use. With its beige-yellowish color, it is optically adapted to honeycomb sandwich panels, which are often used in the production of aircraft.

The adhesive offers consistently high strength under the influence of temperature and after aging as well as a very good media resistance as compared to Skydrol. The flame-retardant product meets the requirements of FST tests according to CS/FAR Part 25 §25.853 (a)(1)(ii) and the Airbus standard ABD0031. In addition, it is a CMR-free product.

Thin epoxy resin adhesive for bonding and potting

26.09.2016/4439/XNUMX | With the epoxy resin adhesive type XNUMX Kager a two-component system in the range that can be used in an extremely versatile way for connection and potting tasks. In practical use it is initially very flowable, after a few hours it hardens to a shore hardness of D80. In addition, the adhesive is suitable for numerous different material combinations.

26.09.2016/4439/XNUMX | With the epoxy resin adhesive type XNUMX Kager a two-component system in the range that can be used in an extremely versatile way for connection and potting tasks. In practical use it is initially very flowable, after a few hours it hardens to a shore hardness of D80. In addition, the adhesive is suitable for numerous different material combinations.

Due to its chemical and physical properties, the two-component reactive adhesive Epoxy 4439 covers a very wide range of applications. In a wide temperature range from -40° to +250 °C it can be used both as an adhesive and as a casting compound. Since it has a very low viscosity - i.e. high flowability - of 1500 mPas after mixing its two solvent-free components A and B, it easily penetrates into thin gaps and fine cracks during application.

In this capacity, the Epoxy 4439 can be used as a highly effective bonding agent for tasks in the Module assembly or serve in maintenance. Since it is also suitable for numerous material combinations of metals, technical glasses, technical ceramics as well as many duromers and thermoplastics, it is currently being used by users in the automotive and industrial sectors, among others wind power technology employed.

As a casting compound, Epoxy 4439 is particularly suitable for applications in electronics and electrical engineering. The low viscosity of the yellowish transparent resin hardener mixture ensures that even tight gaps are filled tightly. During casting, the adhesive hardens to a Shore hardness of D80. It offers electronic and electrotechnical assemblies a protective and mechanically resilient casing.

It can be used practically Glue easily at room temperature, whereby its two components, resin and hardener, can be mixed well. This is best done with a mixer. When gluing, the mix is applied evenly to the surfaces to be glued and then hardens with almost no shrinkage.

You might also be interested in...