In the modern manufacturing engineering Measuring machines ensure that precision and efficiency in quality assurance and production monitoring are improved. We report here on innovative measurement technologies like this 3D coordinate measuring machine or Measuring machine for gear measurement and show how these technologies can improve your measurement results.

Contents

- Precise measuring and intuitive profile projector

- Analytical measuring machines for gears of all kinds

- Surface metrology with multi-sensor technology

- Automated optical 3D coordinate measuring machine

Precise measuring and intuitive profile projector

May 08.05.2019, XNUMX | Dr. Heinrich Schneider measurement technology introduces the PV 360 profile projector. The table version can compare or measure. The precise devices have a long service life. Regardless of whether it is a 2-axis digital display (Y-axis, Z-axis) or M2 measurement and measuring software, with or without an edge sensor: all variants are fully operational and intuitive to use without any additional accessories.

May 08.05.2019, XNUMX | Dr. Heinrich Schneider measurement technology introduces the PV 360 profile projector. The table version can compare or measure. The precise devices have a long service life. Regardless of whether it is a 2-axis digital display (Y-axis, Z-axis) or M2 measurement and measuring software, with or without an edge sensor: all variants are fully operational and intuitive to use without any additional accessories.

The vertical one is used Profile projector PV 360 when measuring plastic parts, seals, matrices, profiles, etc. While sharp workpiece contours make precise measurements easier, the robust construction ensures everyday operation. The PV 360 has a 360 mm projection screen with crosshairs, LED transmitted light illumination, stencil holder and the 360° rotatable protractor 'Nonius 1'.

There is an optional 3x nosepiece, digital angle display for the projection screen, measuring tables with a larger working area, quick adjustment for X and Y as well as telecentric lenses from 10x to 100x. The extensive accessories include a blackout device, rotary table, precision vice, pair of center supports or manual SK40 rotary axis, concentricity tester and precision jaw chuck with angle indicator.

Telecentric Lens | new developments

Telecentric Lens | new developments

A key feature is the high-performance LED incident illumination, which can easily be retrofitted to the manufacturer's measurement and profile projectors.

Analytical measuring machines for gears of all kinds

06.05.2019 | Kapp Niles Metrology presents the completely newly developed analytical measuring machines KNM 2X, KNM 5X and KNM 9X (picture above) for high-precision measurement of gears, gear cutting tools and rotationally symmetrical workpieces in the diameter range from 0 to 1250 mm. The manufacturer is thus expanding the product range to include a complete series for large-scale manufacturers and customers of frequently changing parts ranges.

All guides and the granite base plates are extremely long-term stable and have identical low expansion coefficients. Air bearings with emergency running properties guarantee perfect and wear-free guides without short-wave errors. Air suspension elements under the base plates safely shield shocks and vibrations, special foundations are not necessary. Ironless linear and torque motors of the rotary tables guarantee ultimate positional accuracy and track accuracy.

Despite the compact design, generous travel ranges ensure a tangential rolling movement to the base circle for each profile. Depending on the requirements, different scanning devices can be used Touch systems be used. The highlights of the KNM 2/5/9X include the “Smart” counterholders, which on the KNM 2X release an extended working area by motorized lowering into the base plate and on the KNM 5/9X machines move radially out of the center of the machine to enlarge the working area .

Rotary table systems for precise workpiece positioning

Rotary table systems for precise workpiece positioning

The use of the further developed Smart-Fastclamping system enables the conversion of workpiece holders, lower centers and calibration balls within a few seconds and significantly reduces non-productive times. The freely positionable control cabinets offer optimal installation options even in confined spaces. Comprehensive evaluation software packages that have been tried and tested worldwide are available for direct access via touch screens on the KNM 2/5/9X.

Surface metrology with multi-sensor technology

17.04.2019 | FRT presents the stand-alone metrology device “Microprof 200” in the third generation as an ultra-stable platform: The completely in-house control and analysis software and more than 20 years of expertise in surface measurement technology form the basis for this. The multiSensorconcept, combined with the hybrid measurement technology, supports production lines all over the world.

17.04.2019 | FRT presents the stand-alone metrology device “Microprof 200” in the third generation as an ultra-stable platform: The completely in-house control and analysis software and more than 20 years of expertise in surface measurement technology form the basis for this. The multiSensorconcept, combined with the hybrid measurement technology, supports production lines all over the world.

The Microprof enables a wide range of measurement tasks to be carried out quickly, efficiently and intuitively. As an established standard measuring device in modern 3D surface measurement technology, it is used in semiconductor, Medicine- And Automotive industry. But also in the Mems/Nano/MST, sapphire, Photovoltaics, mechanical engineering, optics and packaging technology, the devices are used for non-contact measurement of topography, total thickness or layer thickness of samples.

The Microprof can be used due to the optical Multi-sensor technology be used universally. Various optical measurement methods have been combined into a universal device. Depending on the requirements, the device enables a quick overview measurement of the entire sample as well as high-resolution detailed measurements down to the sub-nanometer range. The open combinability creates particular flexibility optical sensors. If necessary, sensors can be retrofitted quickly and easily.

Automated optical 3D coordinate measuring machine

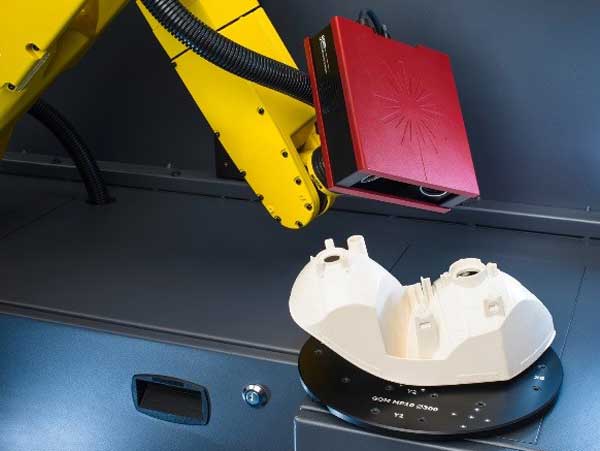

Oct 09.10.2016, XNUMX | In response to increased production and the resulting short measurement times, companies are increasingly using automated measurement and inspection solutions. GOM has developed the optical 3D coordinate measuring machine “Atos Scanbox 4105” for this purpose. The standardized plug-and-play measuring cell is suitable for small and medium-sized components with a maximum weight of 100 kg and a maximum component size of 500 mm.

Oct 09.10.2016, XNUMX | In response to increased production and the resulting short measurement times, companies are increasingly using automated measurement and inspection solutions. GOM has developed the optical 3D coordinate measuring machine “Atos Scanbox 4105” for this purpose. The standardized plug-and-play measuring cell is suitable for small and medium-sized components with a maximum weight of 100 kg and a maximum component size of 500 mm.

Like all measuring cells from the Atos Scanbox It is not tied to one location, but can be set up and put into operation within one or two days. All you need is a power connection. The core of the measuring cell is the robot-guided 3D scanner “Atos Core”, which is used to measure the components in a contactless and three-dimensional manner.

In the standard software solution Virtual measuring room (VMR) the real environment of the measuring cell is simulated so that the movement sequences during the measuring process are simulated virtually. This allows the robot to be controlled without a control panel. It is also possible to prepare the measurement process on CAD without a real component.

All models in the series are specifically designed for production-related applications Inspection and quality assurance has been developed and has already been used in numerous companies such as Daimler, VW, Rolls Royce, Bosch, Honeywell, Samsung, Automotive Lighting and ZF in use. The measuring cells of the 3D measuring machine achieve a higher throughput in industrial production because larger quantities can be analyzed in less time. They also enable greater reproducibility and thus process reliability, as the measurement and inspection processes are applied independently of the operator and at different locations.

Source: This article is based on information from the following companies: FRT, GOM, Kapp Niles Metrology, Schneider Messtechnik.

You might also be interested in...

CAQ Software | Intelligent measurement and testing technology

Universally applicable intelligent CAQ system

Measure solar radiation and determine UV Eruthem radiation

Learn everything about infrared camera measurement technology at Optris

Large wind turbine successfully tested on a system test bench