Online magazine for design and development

Company News

Industry news for your design and development from the specialist areas

Sensors

New sensor class simplifies positioning tasks significantly

cables and wires

PTFE and PFAS free Chainflex cables

Drive Elements

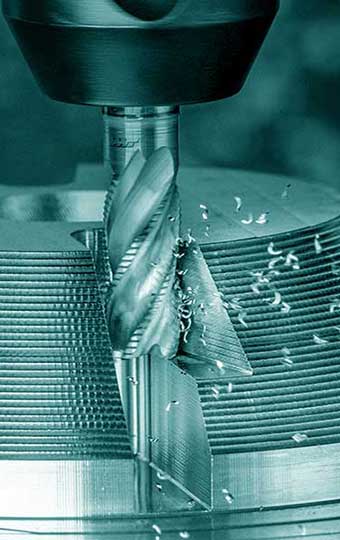

New manufacturing technologies improve crown gear production

IPC

Ex-protected tablet with augmented reality qualities

Industry news for your design and development from the branches

Mobile Machinery

Tailor-made brakes for autonomous forklifts

Mobile Machinery

Cylindrical roller bearings for heavy industrial gearboxes and construction machinery

Automobile

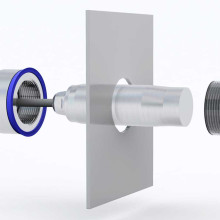

IO module secures hydrogen filling stations from Resato

food technology

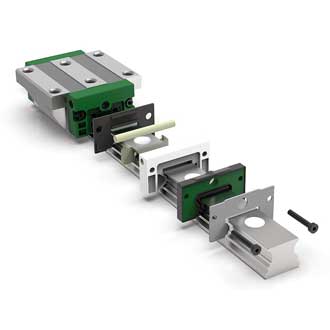

Lubrication and sealing-optimized linear guide

Industry fair news

Pressure sensors | Pressure measurement technology goes digital

- Details

- Hits: 17543

In industry, a wide range of pressure sensors are used to regulate the mechanical measurement of pressure and sometimes also temperature. Analogue and increasingly digital, they are suitable for Pneumatics, Hydraulic System or are electric. With IO Link, one qualifies Pressure sensor for Industry 4.0 applications, it is even more flexible in the dual channel principle. We present these and other new developments here.

Contents

- Pressure sensors 2024 – The most important things in brief

- Ultra-fast pressure transmitter with IO-Link interface

- World's smallest differential pressure sensor with high precision

- Dual channel principle for pressure sensor and conductivity sensor

- Pressure sensor with IO Link interface and analogue output

- Bidirectional differential pressure sensors for extremely low pressures

- Electronic pressure sensor series with IO-Link

- Absolute pressure sensors in a compact Soic housing

- I2C miniature pressure sensors for manifold mounting

- Pressure sensor with capacitive touchpads and iF Design Award

- Avoid printing accuracy errors

- Pressure measuring cell with integrated signal conditioning

- Universal pressure transmitter for 0 to 100 mbar

- Archive for pressure sensors news

- FAQ

Pressure sensors 2023 – The most important things in brief

Pressure sensors are becoming increasingly smaller and are following the trend miniaturization at improved capacity. Advances in Micro-Electro-Mechanical Systems (MEMS) technology are making it possible to produce smaller, cheaper, yet more precise pressure sensors. This miniaturization has opened up new applications, such as wearable medical devices that monitor blood pressure or small sensors for space travel.

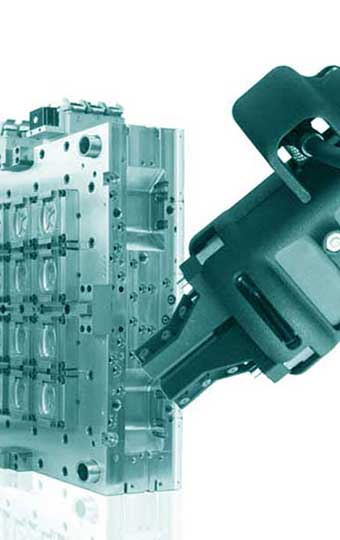

A significant area of application for pressure sensors is: Automotive industry. Here they make a significant contribution to the development of safety, comfort and entertainment. With the progressive development of autonomous and self-driving cars The prevalence of vehicle sensors is expected to continue to grow.

In mechanical engineering, pressure sensors play a crucial role Predictive Maintenanceby continuously monitoring the pressure in machines and systems in real time. This allows changes and anomalies to be detected early, such as blocked filters, leaks or other losses in efficiency in pressure systems. By analyzing the pressure data collected, maintenance teams can identify potential problems before they lead to serious failures.

Ultra-fast pressure transmitter with IO-Link interface

22.07.2022/XNUMX/XNUMX | The new pressure sensor Series KS-I from Gefran offers a digital IO Link 1.1 output and advanced diagnostic functions. The pressure sensors record the pressure and the temperature with a high scanning frequency of 1000 S/s. In this way, the pressure sensor can communicate with the IO-Link master at the maximum speed available for this communication of 230,4 kbaud or COM3.

“Our IO Link solutions digitize the data collected at the field level. This makes the transition to a data-driven company easier for our customers,” explains Torsten Fuchs, Managing Director of Gefran Germany. With their extended connectivity, the pressure transmitters allow the recording of a wide range of acyclic information, which is required for Predictive Maintenance are essential in the Industry 4.0 environment. In addition to pressure and Temperature Top values also include top values achieved and the number of working hours.

Torque measuring shaft determines four measured variables simultaneously

Torque measuring shaft determines four measured variables simultaneously

With regard to cyclic data, the switching logic signal channels SSC, which can be parameterized in detail, and two physical SIO outputs are of central importance. The pressure sensor series covers measuring ranges from 4 bars to 1000 bars with an accuracy better than ±0,5% FS, including hysteresis, non-linearity, repeatability, and span and zero offset. The extended process temperature range from -40° to +125 °C stabilizes the compensated range.

The measuring element of the pressure transmitter is protected by a steel membrane. This makes the sensors particularly resistant to vibrations and mechanical shocks. A pressure sensor from the KS-I series is also immune to electromagnetic interference. Based on Degree of protection IP67 the pressure sensors are suitable for many hydraulic and pneumatic applications.

"The Internet of Things (IoT) thrives on intelligent production processes. These require reliable sensors that minimize errors and optimize process performance through highly accurate measurements. Our pressure transmitters from the new KS-I series meet these requirements in terms of high measurement accuracy and integration into all levels of process automation,” comments Torsten Fuchs.

Gefran exhibits at the K 2022.

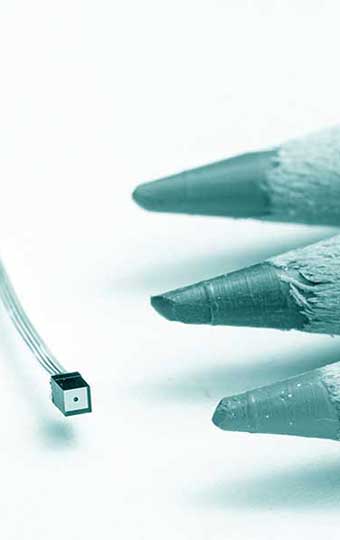

World's smallest differential pressure sensor with high precision

27.04.2021/XNUMX/XNUMX | The world's smallest Differential pressure sensor comes from Sensirion is called SDP3x. The Sensor measures only 5 x 8 x 5 mm. This makes the pressure sensor suitable for many new applications. Based on the next generation of CMOSens sensor chips, the sensor is the heart of the manufacturer's new sensor platform for measuring differential pressure and mass flow.

27.04.2021/XNUMX/XNUMX | The world's smallest Differential pressure sensor comes from Sensirion is called SDP3x. The Sensor measures only 5 x 8 x 5 mm. This makes the pressure sensor suitable for many new applications. Based on the next generation of CMOSens sensor chips, the sensor is the heart of the manufacturer's new sensor platform for measuring differential pressure and mass flow.

The differential pressure sensors of the SDP3x series are suitable for measuring mass flow in a Bypass configuration. The pressure sensors can be soldered reflow and offer a fast response time of 2 kHz with 16 bit resolution. They also offer a few extended functions such as multiple I2C addresses or for interruption.

Like all differential pressure sensors from Sensirion, the digital SDP3x is also very precise, long-term stable and free from zero point drift. All of this makes the differential pressure sensor SDP3x ideal for high-volume and cost-sensitive applications where size is crucial.

The digital, fully calibrated and process temperature compensated differential pressure sensors are available in several versions. The digital SDP31 and the analog SDP36 measure bidirectional differential pressure up to 500 Pa, the digital SDP32 and the analog SDP37 measure up to 125 Pa in the bidirectional flow range.

The digital, fully calibrated and process temperature compensated differential pressure sensors are available in several versions. The digital SDP31 and the analog SDP36 measure bidirectional differential pressure up to 500 Pa, the digital SDP32 and the analog SDP37 measure up to 125 Pa in the bidirectional flow range.

We are responsible for a simple and inexpensive evaluation and qualification of the sensor Evaluation kit to disposal. The SDP3x sensors are available in the following versions:

- SDP31 - digital version (I2C), measuring range: ± 500 Pa

- SDP32 - digital version (I2C), measuring range: ± 125 Pa

- SDP36 - analog version, measuring range: ± 500 Pa

- SDP37 - analog version, measuring range: ± 125 Pa

Areas of application of the sensor are for example Medical devices, Inhalers, lifestyle products and consumer goods, household appliances, drones or anemometers.

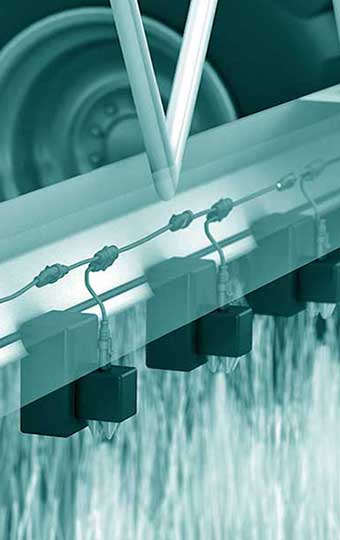

Pressure sensor with IO Link interface and analogue output

April 28.04.2020, 20 | A jury of experts from the food industry selected the pressure sensor type PPXNUMXH from Baumer at the Process Expo in Chicago with the Innovation Showcase Award in the area of dairy products. With the condensate-resistant silicon measuring cell, the outstanding accuracy over the entire temperature range and IO-Link, the pressure sensor prevailed among the 17 finalists.

April 28.04.2020, 20 | A jury of experts from the food industry selected the pressure sensor type PPXNUMXH from Baumer at the Process Expo in Chicago with the Innovation Showcase Award in the area of dairy products. With the condensate-resistant silicon measuring cell, the outstanding accuracy over the entire temperature range and IO-Link, the pressure sensor prevailed among the 17 finalists.

"The trend is towards IO-Link and we are taking this into account with the PP20H sensor," says Bashar Al Hammoud, Product manager for pressure sensors. True to Baumer's motto “Beyond the standard”, the pressure sensor offers another extra. The PP20H also has an analog output in addition to the digital IO-Link interface. “With this combination, the PP20H offers the user more flexibility than any other pressure sensor,” says Baschar Al Hammoud.

When commissioning the pressure sensors, the advantages of IO-Link can be used, which significantly simplify parameterization. And over the 4… 20 mA Analog process connection the pressure sensor can control the process. about IO-Link Further process data such as pressure of the measuring cell and temperature of the pressure sensor and microchip can also be read out in the processing unit.

This leads to interesting conclusions, e.g. B. Whether there is an unusual temperature increase in a container, which indicates a defect or incorrect dosage of the ingredients in the tank. It is the basis for predictive maintenance in the Industry 4.0 environment because high temperatures can reduce the service life of the sensors or other components in the system.

Further IO-Link functions on pressure sensors are being planned

Parameterization is quick, regardless of whether it is before installation or during operation. A new pressure sensor simply learns the parameters of the old pressure sensors via the master and is ready after installation immediately ready for use. Baschar Al Hammoud sees this only as a first step: "We are planning further functions based on IO-Link."

The PP20H has an absolutely tight cell even with a relative pressure measurement. This prevents the penetration of warm, humid ambient air, which threatens to condense at low process temperatures. For example, this is a problem in milk or ice cream processing. Nevertheless, it has to be “open” to the environment to a certain extent because the sensor can also determine the difference to the ambient pressure.

The engineers placed one in the back of the housing barometric pressure sensorwhich measures the reference pressure in the environment via an opening. The actual silicon measuring cell seated in front can thus be hermetically sealed. The PP20H sensor is therefore suitable for pressure measurement in applications such as cleaning with SIP (sterilization in place) and CIP (clean in place) as well as for applications that are subject to sudden changes in process media.

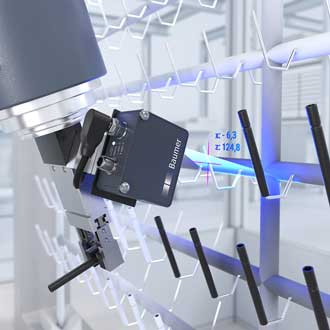

Dual channel principle for pressure sensor and conductivity sensor

February 26.02.2020, XNUMX | Sensors that deliver reliable and precise measured values can create real added value with IO-Link. Baumer provides for greater flexibility Dual channel sensors in front. The pressure sensor PP20H and the conductivity sensor Combilyz AFI from Baumer offer IO-Link Interface now even more interesting functions.

February 26.02.2020, XNUMX | Sensors that deliver reliable and precise measured values can create real added value with IO-Link. Baumer provides for greater flexibility Dual channel sensors in front. The pressure sensor PP20H and the conductivity sensor Combilyz AFI from Baumer offer IO-Link Interface now even more interesting functions.

For example, they can be parameterized quickly and easily - even during operation. Thanks to Dual Channel, the sensors can be operated analog, digital or via the respective channel at the same time.

Additional data such as the simultaneous output of several process data or diagnostic messages can now be communicated to the controller. If required, diagnostic messages can also be read from the sensor's memory. In addition to the digital interfaces, the sensors also have one or more conventional analog outputs.

The conductivity sensor Combilyz AFI and the Pressure sensor PP20H dual-channel principle can therefore be operated in classic control topologies and in a digital IO-Link control concept, depending on which channel is required. The analog interface is still useful for process automation if users want to connect the sensor to an existing controller.

When commissioning the sensor, the advantages of IO-Link come into play. Users can set parameters quickly and easily or use the additional data. For process control, the conductivity or pressure values can be read out in parallel via a 4… 20 mA analog output.

IO-Link to transfer data

By IO-Link valuable additional data for monitoring are transmitted. Process data include the temperature value of the sensor or, for the PP20H, the process temperature. Interesting conclusions can be drawn from this as to whether there is an unusual rise in temperature in a pipe or container. This enables, for example, monitoring for predictive maintenance.

Parameterization software for IO-Link sensors for the Moneo platform

Parameterization software for IO-Link sensors for the Moneo platform

In addition to the conductivity of the media, the conductivity sensor provides information about their concentration values. This makes it possible to precisely determine which medium is in the process and in which concentration. In addition to the process pressure, the ambient pressure can be determined with the pressure sensor. This means that the sensor can be used for absolute and gauge pressure measurements.

Direct combination of sensor data

Via IO-Link and the controller, the sensors Communicate with each other bidirectionally. Measured values from one sensor can thus be used in another sensor. This enables complex measurement tasks to be solved and processes to be optimized. The conductivity sensor can be based on the measured values of a Temperature sensor in the machine, which shortens the response time of the temperature measurement for temperature compensation of 15 s or can be avoided completely.

Within the level measurement In closed tanks, the filling level status can be shown directly on the DFON display by combining the measured values of two pressure sensors. For this purpose, the status of the pressure sensor for head pressure measurement transmitted via IO-Link is transmitted to the sensor on the bottom of the tank in order to adjust its zero point. This enables the pressure in the tank to be determined.

With the integration of the digital Communications interfaces at Combilyz AFI and PP20H, Baumer continues to expand its portfolio of process sensors with IO-Link. In addition, solutions for flow and level measurement with the digital communication standard are available.

Bidirectional differential pressure sensors for extremely low pressures

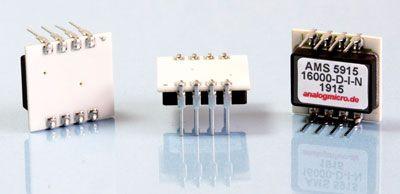

19.11.2019 | Analog Microelectronics presents a new bidirectional differential pressure sensor for the ultra-low pressure range and thus expands its digital board-level pressure sensor series AMS 5915 with I2C output. The AMS 5915-0002-DB enables the precise measurement of extremely low differential pressures in the range from -250 Pa (-2,5 mbar) negative pressure to 250 Pa (2,5 mbar) positive pressure.

19.11.2019 | Analog Microelectronics presents a new bidirectional differential pressure sensor for the ultra-low pressure range and thus expands its digital board-level pressure sensor series AMS 5915 with I2C output. The AMS 5915-0002-DB enables the precise measurement of extremely low differential pressures in the range from -250 Pa (-2,5 mbar) negative pressure to 250 Pa (2,5 mbar) positive pressure.

The membrane basede differential pressure sensor has a bursting pressure of 200 mbar, is completely gas-tight and is particularly suitable for ultra-low-pressure applications in industry, air conditioning technology (HVAC) and medical technology. The PCB-mountable AMS 5915-0002-DB is digitally calibrated, linearized and extensively temperature-compensated over a wide operating temperature range from -25° to +85 °C. It has a resolution of 14 bits and is suitable for system integration with a supply voltage of 3,3 V and the I2C interface. The sensor achieves an overall error of TEB < 2% FSO over the entire operating temperature range without additional zero point adjustment at the system level.

Temperature Transmitter | Industry novelties and applications

Temperature Transmitter | Industry novelties and applications

The combination of a high quality MEMS elements with a modern mixed-signal ASIC on a Ceramicssubstrate also guarantees excellent long-term stability. With a response time of typically only 0,5 ms, the sensor is also very suitable for fast measurements. Two housing variants are available: ceramic DIL package with vertical pressure connections for hose assembly or without hose connections for the seal with O-rings. Analog Microelectronics offers a USB starter kit for easy evaluation of the AMS 5915-0002-DB.

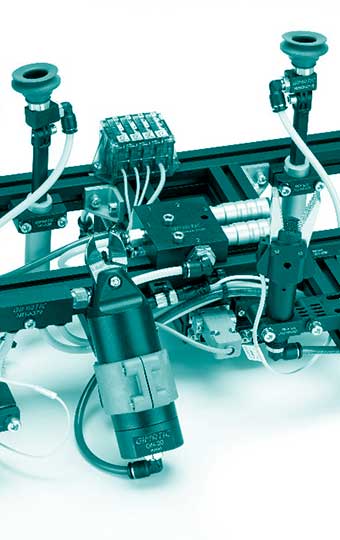

Electronic pressure sensor series with IO-Link

11.11.2019 | IMI Precision Engineering has expanded its range of pressure measurement technology solutions with two new electronic pressure sensors with IO-Link connectivity. The electronic Norgren sensors 34D and 54D are suitable for automatic monitoring of the pressure level in pneumatic systems or for more complex monitoring functions in applications with water, hydraulics or other media.

11.11.2019 | IMI Precision Engineering has expanded its range of pressure measurement technology solutions with two new electronic pressure sensors with IO-Link connectivity. The electronic Norgren sensors 34D and 54D are suitable for automatic monitoring of the pressure level in pneumatic systems or for more complex monitoring functions in applications with water, hydraulics or other media.

The user-friendly pressure sensors are easy to install, can be quickly set up via buttons or remote access via IO-Link set up and provide accurate collection of application performance data.

The compact and lightweight 54D is suitable for monitoring general vacuum and compressed air applications 16 up bar. It offers an optional differential pressure measurement, with which e.g. B. the pressure difference between the inlet and outlet of a filter can be monitored in order to proactively draw attention to an upcoming maintenance requirement.

With nine different pressure levels from vacuum up to 600 bar, the 34D is housed in a robust stainless steel housing, making it the ideal solution for operating in harsh and aggressive process control environments. With its 18 design variants and standard IO-Link connectivity, it is predestined for machine builders looking for a flexible, data-driven alternative.

Absolute pressure sensors in a compact Soic housing

12.06.2019/1131/XNUMX | With the new "Barometric Air Pressure" (BAP) sensor SMXNUMX Amsys a high-precision absolute pressure sensor in a compact SOIC-8 housing for SMD assembly for medical technology, among other things. The compact OEM sensors for measuring barometric air pressure in the range from 150 to 1800 mbar offer 16-bit signal processing and an accuracy of 1 mbar in the temperature range from 0 to 80 °C.

12.06.2019/1131/XNUMX | With the new "Barometric Air Pressure" (BAP) sensor SMXNUMX Amsys a high-precision absolute pressure sensor in a compact SOIC-8 housing for SMD assembly for medical technology, among other things. The compact OEM sensors for measuring barometric air pressure in the range from 150 to 1800 mbar offer 16-bit signal processing and an accuracy of 1 mbar in the temperature range from 0 to 80 °C.

The entire working temperature range is with -40° to 125°C very broad and enables versatile use with a still very good accuracy of 2 mbar.

The output of the pressure and temperature-proportional information takes place via I²C interface. Alternatively, a ratiometric analog output (SM1111) or a version with a digital SPI output (SM1171) are available. The integrated ASIC enables calibration and temperature compensation during manufacture. The fully matched SM1131 are offered in a standardized Soic8 package for automated SMD assembly. The Soic pressure sensors are self-sufficient and do not require any additional circuitry.

The pressure sensors are suitable for Applications, where the barometric air pressure or low relative pressures in price-sensitive areas must be determined by consecutive measurements, such as in medical technology, blood pressure measurement, negative pressure wound therapy or weather observation.

I2C miniature pressure sensors for manifold mounting

04.06.2019 | Analog microelectronics is expanding its digital board level Miniature pressure sensors AMS 5915 with I2C output with special variants for pneumatic applications. This PCB mountable sensor in the ceramic DIP-08 housing is designed for manifold mounting on flanges with O-ring seals. They are only about 4 mm high. The pressure range of the sensors includes both relative pressure and differential pressure measurements up to 16 bar with an overpressure resistance of 30 bar.

The force sensors AMS 5915 are suitable for both relative pressure measurement and differential pressure measurement up to 16 bar with an overpressure resistance of 30 bar. Due to their special structure, the sensors are one-sidedly compatible with liquids, i.e. H. During relative pressure measurements, non-corrosive liquids can also be measured in addition to gaseous media thanks to the pressurization on the back.

The high-precision, digital miniature pressure sensors have a resolution of 14 bits and are suitable with their I2C interface and a supply voltage of 3,3 V ideal for microcontrollers. They are digitally calibrated, linearized and temperature-compensated in a wide operating temperature range from -25° to +85 °C, which results in a low overall error of TEB < 0.5% FSO in the entire operating temperature measuring range. The combination of a high quality MEMS element with a modern mixed signal IC on a ceramic substrate guarantees high long-term stability. With a response time of typically just 0,5 ms, the sensors are also suitable for fast measurements.

Pressure sensor with capacitive touchpads and iF Design Award

08.04.2019 | The robust pressure sensors of the newly developed "PS+" series from Turck are the first products in a modular fluid sensor family that provide customers with reliable and intuitively operated measuring instruments. The sensor was already awarded the iF Design Award at the product launch.

08.04.2019 | The robust pressure sensors of the newly developed "PS+" series from Turck are the first products in a modular fluid sensor family that provide customers with reliable and intuitively operated measuring instruments. The sensor was already awarded the iF Design Award at the product launch.

The PS+ pressure sensors are particularly easy to put into operation. Overhead mounting is possible, as is rotation of the sensor head within a range of 340°. After connection, the sensor automatically registers whether the control or the bus module requires a PNP or NPN, or current or voltage signal. A compatibility mode is also available for integration into IO-Link systems. The user interface with capacitive touchpads and a bi-color display allows quick settings in the plain text menu (according to Turck or VDMA standards) and is protected from accidental incorrect operation by a locking mechanism.

The side effect of the hermetically sealed control unit is greater resistance to dirt and liquids, which is why the sensors have the ISODegrees of protection Meet IP6K7K, IP6K7 and protection class IP 6K9K. The PS+ series is designed for pressure ranges up to 600 bar and is available with ceramic measuring cells (PS310) and metal measuring cells (PS510). The latter have an overpressure resistance of up to seven times the nominal pressure. The sensors can optionally be equipped with pressure peak apertures.

Turck will be his new one fluid sensors-Expand portfolio over the course of the year to include products for temperature and flow measurement. Since all sensors are based on the same platform, they will be very similar in appearance and operation.

Avoid printing accuracy errors

The Calibration of pressure sensors is determined by factors such as zero point error, span error and non-linearity. The video from Wika explains, among other things, what accuracy actually means in pressure sensors and how inaccuracies, i.e. deviations from the desired measurement result, come about.

Pressure measuring cell with integrated signal conditioning

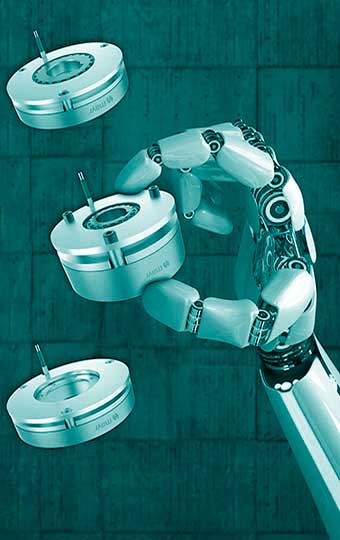

01.07.2018 | With the Ceros S01 M from Jumo digitization has arrived in pressure measurement technology. The pressure sensor with integrated signal conditioning is an active component that provides a temperature-compensated and calibrated digital/analogue output signal for measuring pressure and temperature values. The compact design makes it particularly suitable for critical installation situations.

01.07.2018 | With the Ceros S01 M from Jumo digitization has arrived in pressure measurement technology. The pressure sensor with integrated signal conditioning is an active component that provides a temperature-compensated and calibrated digital/analogue output signal for measuring pressure and temperature values. The compact design makes it particularly suitable for critical installation situations.

The pressure measuring cell works with a piezoresistive measuring system and is available in measuring ranges from 100 mbar to 100 bar relative and from 1 to 100 bar absolute. The operating temperature is between -40° and +125 °C. Customer-specific measuring ranges, compensation temperatures and designs are also possible.

The pressure measuring cell offers high accuracy and a fast response time. The improved temperature stability increases the reliability of the sensor. Since the Ceros S01 M is delivered completely calibrated and adjusted, additional devices such as climate cabinets, pressure controllers or calibration systems are not required. This saves installation time and, of course, reduces costs.

To minimize welding or installation errors, a Subsequent zero point adjustment possible. The overvoltage, reverse polarity and high ESD protection also simplify the application. Due to the low energy requirement, the Ceros S01 can also be operated with batteries. It is used, for example, in level probes, data loggers or digital manometers. Due to the low surface roughness, it can also be used in hygienic areas.

Universal pressure transmitter for 0 to 100 mbar

19.02.2018/XNUMX/XNUMX | The applications for analog pressure transmitters are diverse. However, the place of use determines the maximum size and the choice of materials for the diaphragm and housing. It is therefore ideal if analogue pressure sensors can be individually adapted to their areas of application. Beck pressure control technology has therefore now expanded its wide range of compact pressure switches with the analog pressure transmitter 981.

Stand for a variety of different applications tried and tested membranes as well as a huge selection of screw, flange and plug-in connections made of a wide variety of materials. The sensor is very compact with only 45 mm diameter at 59 mm height (including 15 mm connecting piece) and can be easily integrated everywhere. With an extensive range of mounting brackets, it is also quickly mounted in an individual installation position.

Most compact Atex pressure switch in its class for hydraulics

Most compact Atex pressure switch in its class for hydraulics

The pressure sensor offers a selectable measuring range between 0 and 100 mbar with a linearity of less than ±1% FSO BFSL @ 20 °C. This pressure measuring range required by the customer is already set individually upon delivery, so that the pressure sensor can be installed in the application by the end customer immediately.

The supply voltage of 24 VDC, with a current consumption of < 20 mA and the output signal (load min. 10 kOhm) are transmitted via a four-pole standard M12 flange connector. The response time is 500 ms. The sensor can optionally provide a three-wire output signal with 0-10 VDC or a two-wire output signal with 4 ... 20 mA. For the Monitoring of over and under pressure diaphragms made of different materials are available for liquid or gaseous, also aggressive, media in the range from -20° to +85 °C.

FAQ

What does a pressure sensor do?

A pressure sensor is a device that measures the pressure in a liquid or gas and converts this information into an electrical signal. These sensors are used in a variety of applications where they monitor and regulate pressure.

Which sensor reacts to pressure?

These are different types of pressure sensors including piezoresistive, capacitive, piezoelectric and optical sensor. The physical quantity pressure measuring sensors each have specific properties and suitability for different areas of application.

Where are pressure sensors used?

Pressure sensors are used in many areas. Some typical areas of application are:

- Automobileindustry for monitoring tire pressure, oil pressure in the engine, fuel pressure and air pressure in the brake systems.

- Medicineical devices for monitoring blood pressure, respiratory pressure in ventilators and other critical medical monitoring devices.

- Industrial Process control in monitoring and controlling processes in the chemical, petrochemical, food and beverage industries as well as in water treatment plants.

- Aerospace for monitoring cabin pressure in aircraft and spacecraft as well as in fuel systems.

- Heating, Ventilation, and Air Conditioning (HVACsystems) for monitoring air pressure in heating, ventilation and air conditioning systems.

- Weather stations for measuring atmospheric pressure for weather forecasting.

Source: This article is based on information from the following companies: Amsys, Analog Microelectronics, Baumer, Beck-Druckkontrolletechnik, Gefran, IMI Precision, Jumo, Sensirion, Turck, Wika.

You might also be interested in...

Control Fair 2024 | The industry is already looking forward to Stuttgart

Transducer | Transmitters for pressure, temperature and more

Level sensor | Level switch for simple to IIoT use

encoders | Industrial Ethernet and Industry 4.0 encoders

Ultrasonic sensor | For distance, distance and level

PLC | The programmable logic controller

Angela Struck is editor-in-chief of the development scout and freelance journalist as well as managing director of Presse Service Büro GbR in Ried.