How does a Tension spring produced, what influence do tension spring designs, eyelet shapes, spring characteristics and spring materials have and what do technical terms such as preload, relaxation, yield strength and dynamic load mean in a tension spring? This specialist article by Gutekunst Federn answers all of these questions with basic knowledge for the next spring design.

How does a Tension spring produced, what influence do tension spring designs, eyelet shapes, spring characteristics and spring materials have and what do technical terms such as preload, relaxation, yield strength and dynamic load mean in a tension spring? This specialist article by Gutekunst Federn answers all of these questions with basic knowledge for the next spring design.

Tension springs are used as return springs in vehicle construction, for example, as well as in garage doors, locks, bed drawers and in Relais in plant and equipment construction. Sometimes tension spring systems with several tension springs are also used. The most common application examples are garage door spring assemblies or folding mechanisms for bed boxes in parallel connection, where components with a larger mass are held in position with constant forces and spring moments.

Production and material

Tension springs are produced from round or oval spring steel wires. The spring steel wire is placed generally in the cold forming process into any desired shape, either by winding with a finger system around a mandrel or - in fully automatic spring coiling machines - with the help of a plurality of wire guide pins in the two-finger or three-finger system. The eyelets are formed either directly at the winches, or is placed in a downstream operation. Tension springs are usually manufactured cylindrically German with one 1 / 1 eyelet on the sides according to the standard EN-13906 2. Thus, the preparation of a metal spring runs:

Spring designs and Ösenformen

In addition to the cylindrical Zugfederbauform with a linear spring characteristic also conical or barrel-shaped springs are often produced. In this case, a longer life is with the tapered spring ends, in addition to a progressive spring characteristic, is achieved. A degressive force profile can not be created on the Zugfederbauform. For this, a spring-lever mechanism is necessary, as in a bed frame.

In addition to the cylindrical Zugfederbauform with a linear spring characteristic also conical or barrel-shaped springs are often produced. In this case, a longer life is with the tapered spring ends, in addition to a progressive spring characteristic, is achieved. A degressive force profile can not be created on the Zugfederbauform. For this, a spring-lever mechanism is necessary, as in a bed frame.

Depending on the application, different Ösenformen used. In addition to classic Ösenformen as the 1 / 1 German eyelet or hook eye also more resilient spring ends as the rolled threaded bolts or threaded plug einschraubte whereby a higher life time are offered. In general, due to the tension springs eyelets are not suitable for continuous hard use since the Ösenanbindung is a major flaw in the transition curve.

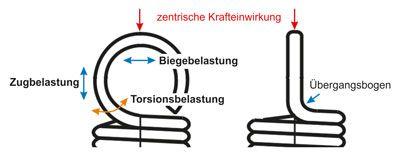

In Zugfederösen three forces occur: tensile, torsional and bending loads. Thus, one should also be taken to ensure that the force is applied centrally on the eye, otherwise increases the risk of Ösenbruchs with tension springs. In addition, the transition radius (r) of the spring body to the spring eye must generally be greater than the wire thickness (d).

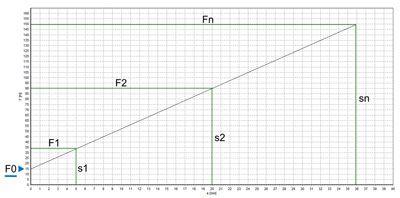

Most desired bias

When the tension spring during manufacture by a spin against the next turn a bias voltage is produced. This bias is mostly desired, because thereby the required operating length of the spring is minimized. the production cost, the higher the bias voltage, the higher: However applies when Zugfederherstellung. The bias is also the winding ratio "w = D / d" (D = mean coil diameter, d = wire size) dependent. It decreases with increasing winding ratio.

When the tension spring during manufacture by a spin against the next turn a bias voltage is produced. This bias is mostly desired, because thereby the required operating length of the spring is minimized. the production cost, the higher the bias voltage, the higher: However applies when Zugfederherstellung. The bias is also the winding ratio "w = D / d" (D = mean coil diameter, d = wire size) dependent. It decreases with increasing winding ratio.

at a tension spring if no bias is desired, such as at a measuring spring, this can be removed by a higher tempering temperature and longer annealing time later almost completely. Also thermoformed springs contain no bias. In order to guarantee the required spring characteristics, such as dimensions or strength characteristics after manufacture, the bias voltage (F0) or the average coil diameter (D) is tolerated as production compensation normally.

Relaxation, shear stress and spring forces

Is the mainspring charged over a longer period at higher temperatures, is - as with all metal springs - lost a certain percentage of the spring force. This power loss is called relaxation. It increases with increasing temperature and voltage. Since the relaxation can mean a loss of power of up to 20% depending on material and temperature, the greatest travel should not exceed 80% of the allowable voltage.

Is the mainspring charged over a longer period at higher temperatures, is - as with all metal springs - lost a certain percentage of the spring force. This power loss is called relaxation. It increases with increasing temperature and voltage. Since the relaxation can mean a loss of power of up to 20% depending on material and temperature, the greatest travel should not exceed 80% of the allowable voltage.

Exceeds load of the tension spring, the shear stress the allowable value of the yield strength, enters a permanent reduction of the bias or a deformation of the tension spring. Furthermore, attention should be paid to the resonant vibration of the mainspring. Ideally, the vibrations of the exciter frequency are ten times lower than the natural frequency of the spring, otherwise significant stress risers can occur, which lead to spring breakage.

The spring / spring stiffness depends on the spring wire and the spring rate or spring constant from. The spring rate also defines the ratio of spring force to travel. In principle, the dimensioning of the spring force can be influenced by the following measures:

- Wire diameter (d) larger> spring harder

- Coil diameter (De) larger> spring softer

- Number of resilient coils (n) greater> spring softer

dynamic load

Dynamic loads are time-varying loads with more than 10.000 strokes. Unlike compression springs there is no Fatigue strength diagrams with which a possible dynamic stress field is given due to the material, the wire diameter and the stroke voltage for tension springs. The reason is the variety of Ösenformen that do not fatigue strength largely because of the transition curve of the spring body to the eyelet. Ösenformen as the screwed-threaded plug or rolled threaded bolt have better dynamic properties. Nevertheless, every time dynamically inserted spring real life tests have to be performed for the respective labor.

Spring material and surface

The selection of the spring steel wire affects not only the spring force, it also provides the right characteristics for the respective spring application. Including stainless spring steels, SiCr alloyed valve spring wire, copper alloys for good electrical properties, nickel alloys for high heat and corrosion resistance as well as titanium alloys are used for the highest standards of aviation technology in addition to the normal non-alloy spring steel wires. In addition, various surface treatments can be applied to optimize the spring. The tension springs, however, a surface treatment is difficult because the turns are so close to each other. #

The selection of the spring steel wire affects not only the spring force, it also provides the right characteristics for the respective spring application. Including stainless spring steels, SiCr alloyed valve spring wire, copper alloys for good electrical properties, nickel alloys for high heat and corrosion resistance as well as titanium alloys are used for the highest standards of aviation technology in addition to the normal non-alloy spring steel wires. In addition, various surface treatments can be applied to optimize the spring. The tension springs, however, a surface treatment is difficult because the turns are so close to each other. #

Advantages and disadvantages of tension springs

The disadvantages of the tension spring lying in the size of the installation space, of the sensitive spot on the eye connection and the resulting total loss of the spring force for a Ösenbruch. The main advantages of the tension spring, the bending freedom, the possibility of the central force transmission and the freedom from friction due to the elimination of guide elements, such as sleeve or mandrel.

To learn more about these topics more or have questions, then you are in good hands when Gutekunst springs Info blog at blog.federnshop.com. In the knowledge and information channel of Gutekunst on the subject of metal springs can be found not only on tension springs interesting and useful information.