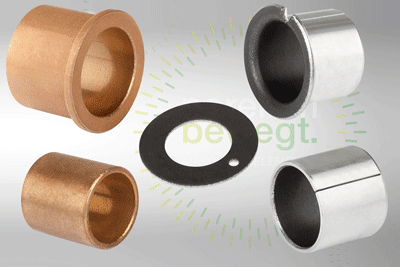

The ready-to-install plain bearings made of a steel-bronze-plastic composite or made of pure sintered bronze are self-lubricating and therefore maintenance-free. They are used in both dry-running and lubricated applications in a wide range of electrical device, machine and plant engineering. The plain bearings have a high chemical resistance and meet the RoHS directive of the EU. At Norelem they are available as bushings and flange bushings with an inside diameter of 3 to 50 mm and as thrust washers.

The ready-to-install plain bearings made of a steel-bronze-plastic composite or made of pure sintered bronze are self-lubricating and therefore maintenance-free. They are used in both dry-running and lubricated applications in a wide range of electrical device, machine and plant engineering. The plain bearings have a high chemical resistance and meet the RoHS directive of the EU. At Norelem they are available as bushings and flange bushings with an inside diameter of 3 to 50 mm and as thrust washers. The rolled composite plain bearings made of steel and sintered bronze are particularly suitable for dry running. With a copper-tin coating, the carrier plate is protected against corrosion, inside sintered bronze in combination with a layer of embedded PTFE and slip additives ensures friction-free rotation. The combination of materials ensures optimum and practically wear-free sliding properties with maximum carrying and thermal conductivity. It avoids flow of the slip additives even at high bearing loads. Composite plain bearings are also suitable for lubricated applications as well as for rotational and oscillatory movements. The plain bearings have no stick-slip effect and absorb hardly any water.

Sintered bronze bearings are oil-soaked and self-lubricating: they transfer oil from their receptive capillary system to the rotating shaft, which is then absorbed by the plain bearing at standstill. Under normal operating conditions, an additional lubrication is not required. Due to their ability to store oil sintered bronze bearings are particularly suitable for endurance runners such as electric motors, fans and household appliances. The installation of the cost-effective plain bearings is easy and is done with the help of a suitable Einpressdorns.