At the special show “Man - Machine - Future” at the Packaging Excellence Center, Schmersal will be presenting safety systems that support packaging companies in the introduction of digital technologies. The industry manager gives insights into the market for packaging machines and systems, describes current topics and trends and explains which safety-related solutions are best suited for the packaging industry.

At the special show “Man - Machine - Future” at the Packaging Excellence Center, Schmersal will be presenting safety systems that support packaging companies in the introduction of digital technologies. The industry manager gives insights into the market for packaging machines and systems, describes current topics and trends and explains which safety-related solutions are best suited for the packaging industry.

In the year 2013 the worldwide production volume of food and packaging machines amounted to about 30,3 billion Euro. German manufacturers had a share of about 6 billion euros with an export quota of 87%. This makes them world market leaders. The most important single markets for packaging machines are Europe and Asia. With some distance follows North America, where German manufacturers also dominate. There are enough competitors in this industry. If we compare the product and service portfolios of the individual companies, we believe we have the world's largest portfolio of security components as well as a global, high-performance sales network with our own service division.

Specific requirements for the industry

In general, safety technology should reliably protect the operating personnel of packaging machines and systems, safeguard the processes taking place in them, while production processes must not be impaired or interrupted. The special requirements of these industries have to be taken into consideration, because packaging machines and systems are very product-specifically designed and often an integral part of complete processing or production systems. They mostly work with very high clock rates and are becoming ever more complex. In addition, in the medical and pharmaceutical industry as well as in the area of food and beverages, in addition to the machinery directive, further very specific safety standards and regulations must be observed.

In general, safety technology should reliably protect the operating personnel of packaging machines and systems, safeguard the processes taking place in them, while production processes must not be impaired or interrupted. The special requirements of these industries have to be taken into consideration, because packaging machines and systems are very product-specifically designed and often an integral part of complete processing or production systems. They mostly work with very high clock rates and are becoming ever more complex. In addition, in the medical and pharmaceutical industry as well as in the area of food and beverages, in addition to the machinery directive, further very specific safety standards and regulations must be observed.

A few points should be mentioned here: The devices must have a high density and the materials must be correspondingly resistant to cleaning chemicals. Hygienic design is a central requirement in packaging machine construction for food and pharmaceutical products, because it is ruled out that z. B. the food to be packaged are contaminated or that the plant operator comes to be packaged or filled with drugs in contact. It also depends on temperature resistance, because, for example, the processing and packaging of food in a wide temperature range. Explosion protection is about ensuring maximum safety when packaging flammable, powdery materials. Of course, all of this has implications for the security solutions to be used and their design.

Most demanding requirements of the industry

The protection of employees is always the top priority. A distinction is made between primary, secondary and tertiary packaging. In terms of hygiene, the requirements for primary packaging in the food, beverage and pharmaceutical industries are certainly the highest, because the switchgear can come into more or less direct contact with food, and contamination must be ruled out here. The different environmental conditions are also a challenge: moisture, strong temperature changes, the regular use of cleaning agents and disinfectants are critical aspects that must be taken into account when designing safety-related solutions.

Dominant topics and trends

The food industry is facing an increasingly aging society and single households. More and more convenience products have to be packed, the packaging volume increases and ever higher quantities are the result. At the same time, the demand from trade and consumers for a large variety of products and packaging as well as for new products and taste experiences is increasing. This requires frequent format changes with the least possible changeover times. Therefore, security solutions must be designed so as not to affect the productivity and availability of the equipment. The pharmaceutical industry is already ready to package and deliver patient-specific, personalized medicines. This requires a maximum of flexibility in the form of production batches in very small quantities down to the number of 1 units.

Serialization is also an important topic in the pharmaceutical industry: In order to ensure the consistent traceability of products and to avoid a "gray drug market", a swap of the products must be ruled out. This is possible, for example, with the help of protective doors that prevent employees from intervening in the production process. In these cases, we pursue a reverse objective: we must protect the production processes from unauthorized persons. And the aforementioned number of 1 leads to industry 4.0 concepts, which are currently being discussed heavily.

The role of security technology providers

Increasingly, packaging machine manufacturers want to procure the various safety components for their machines as a complete system solution from a single source, including comprehensive consulting and services. Because neither they nor their customers want to deal more than necessary with the safety technology. This should work fail-safe. As a system supplier, we are thus involved in the new and further development of packaging machines at a very early stage and can develop appropriate security concepts and solutions for the users.

Increasingly, packaging machine manufacturers want to procure the various safety components for their machines as a complete system solution from a single source, including comprehensive consulting and services. Because neither they nor their customers want to deal more than necessary with the safety technology. This should work fail-safe. As a system supplier, we are thus involved in the new and further development of packaging machines at a very early stage and can develop appropriate security concepts and solutions for the users.

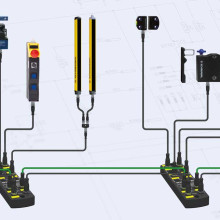

In addition, we would like to actively shape the topics and trends in the industry. For example, we work in various standardization committees, committees and trade associations to define safety standards and to develop practicable solutions suitable for industrial use together with packaging machine manufacturers. Last but not least, Schmersal has established its own branch management for the food industry. Our range of products for packaging machine construction includes various command and signaling devices in different degrees of protection up to IP69K, position switches and sensors for position detection, energy-efficient safety switching devices for protective door monitoring, safetyPhotocells and grids, safety relays and safety controls.

Schmersal and the packaging technology

The packaging industry is very interesting for us as a provider of security solutions, because almost all sectors need packaging machines and systems. Many companies in these industries are very creative when it comes to the design of packaging for promotional product presentation. It is estimated that in Europe alone every year around 100.000 new products come on the market for their packaging machines and equipment and of course security solutions are needed. The need is so huge. As a result, the need for safety engineering in these industries is also great.

Because our security solutions are based on the products to be processed and packaged as well as the processes involved, we often develop special solutions for our customers. In return, we also supply standard products in large quantities for many applications.

Personal fascination

I think the food industry as well as the packaging machine builders can help - or at least curb - a serious societal and humanitarian problem: on the one hand, more than 870 million people worldwide are starving, and on the other, 1,3 billion per year is spoiling Tons of food: They are thrown away or lost, among other things because they are not stored properly and packed in a timely manner.

You have to change that as soon as possible. The consequence is that more high-quality packaging is needed worldwide in the long term, protecting the food from spoiling and prolonging its shelf life. This means that the market will continue to grow. Of course, this growth must not be at the expense of the environment, the used packaging must be recycled - efficient recycling systems are therefore the next big challenge, but at the same time a great opportunity for further growth.

You might also be interested in...

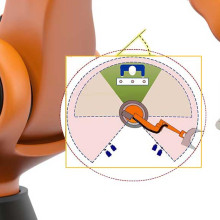

This is how you build a collaborative robot cell

Safe field box with reduced wiring effort

RFID and Barcodes | Industrial identification

Light barrier, light grid, light curtain for safety

3D Camera | Industrial image processing