Discover the latest developments in the field of Dog clutch – decisive for high-performance drive systems. Our expert insight highlights how these couplings can increase efficiency and reliability. What is very important with elastomer couplings is the plastic or that elastomer, which need to be constantly improved so that they become more efficient.

Contents

- Claw clutch for slip-free power transmission

- New sprocket makes clutches 40% more powerful

- High-speed clutch with high concentricity

- Slip clutch to protect people and machines

- Claw coupling for ball screw + trapezoidal thread spindle

- Elastomer coupling with new hubs and spacers

- Elastic clutch with more torque and longer life

- Flexible jaw coupling for corrosion atmospheres

- Torsionally rigid elastomer claw couplings for high speeds

- Claw Couplings Archive

- FAQ

Claw clutch for slip-free power transmission

What is special about the claw coupling is its robust, low-maintenance design, which enables direct, slip-free power transmission and ensures precise alignment between connected shafts. The current development focuses on high-strength materials and advanced manufacturing methods to extend service life and reduce maintenance.

With their ability to transmit torque precisely, claw couplings are particularly suitable for applications where accuracy is required, such as those found in automated production lines and in the Robotic can be found. Increase your machine efficiency with the latest claw couplings for maximum precision and speed in drive technology.

New sprocket makes clutches 40% more powerful

07.11.2023 | KTR Systems has a new sprocket in its range that increases the performance level of the clutch by around 60 percent at temperatures above 40 °C. The TPU sprocket is primarily used in the Rotex GS servo coupling. But he can also go to the Standard Rotex couplings be used.

07.11.2023 | KTR Systems has a new sprocket in its range that increases the performance level of the clutch by around 60 percent at temperatures above 40 °C. The TPU sprocket is primarily used in the Rotex GS servo coupling. But he can also go to the Standard Rotex couplings be used.

Drives with permanent temperatures of 60° to 120°C, such as those found in servohydraulics and backlash-free gearboxes, are the main areas of application.

The TPU sprocket offers extreme pressure resistance while retaining all positive technical properties such as abrasion resistance and cushioning. There is also a low temperature factor. Even below 60 °C, performance is increased by 40%.

Extreme compressive strength at elevated temperatures

The TPU has hardness levels of 52 and 65 Shore D. The plastic was tested at the KTR research center in Rheine up to 120 °C at a nominal torque without torque reduction due to the temperature factor in terms of function, component strength, wear and service life. The result: The permanent deformation after the endurance test at 60° C was significantly smaller than with standard polyurethanes.

The sprocket can be combined with all hub variants from the backlash-free Rotex GS servo coupling range. It is available for sizes 19, 24, 28, 38 and 42.

High-speed clutch with high concentricity

March 30.03.2023, XNUMX | High speeds are particularly challenging for a clutch because inaccurate transmission of the rotational movement can have a negative impact on the dynamics and efficiency of the drive. A high level is therefore required for precise transmission of the rotational movement concentricity important.

Clutches also have to withstand the heavy loads that arise from high acceleration at high speeds. Spindle freedom and wear resistance of the elastomer are important for reliable performance.

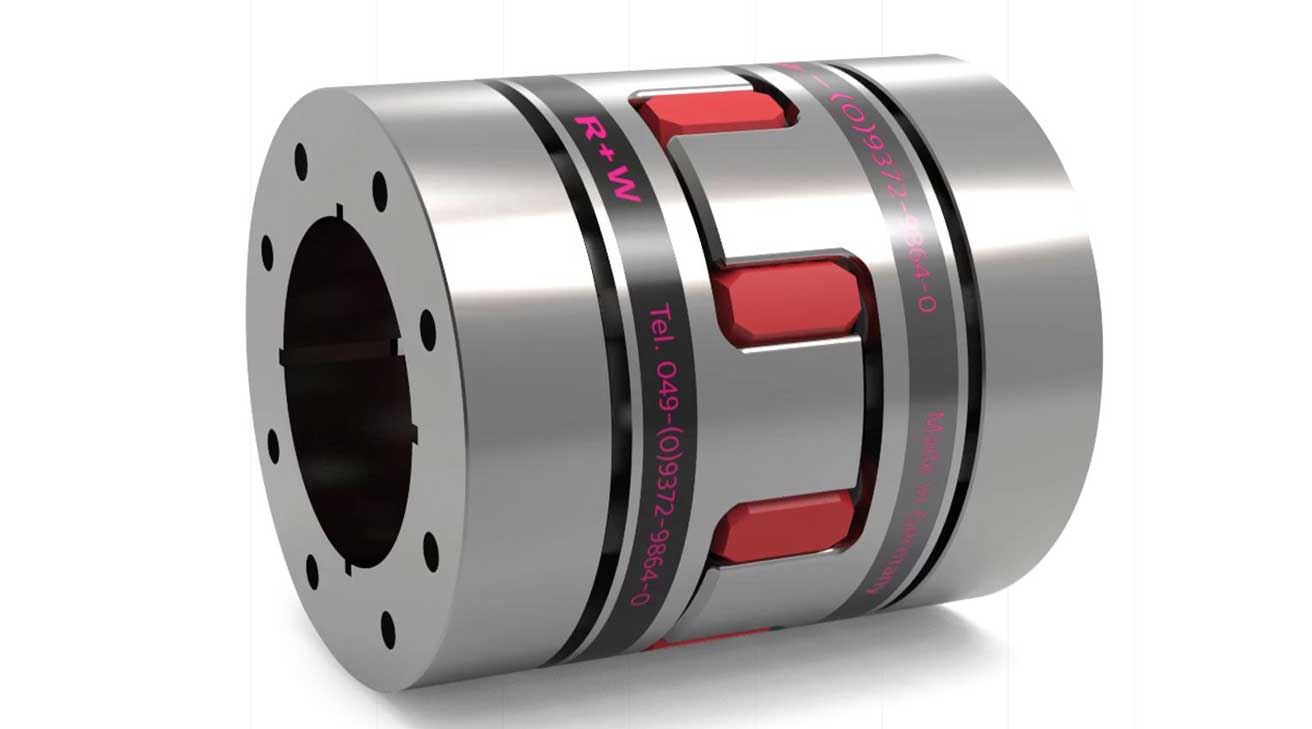

R+W drive elements has developed the SP6 high-speed clutch (pictured above) for these requirements. It is a modern and powerful drive element for spindle drives and other high-speed applications.

The Elastomer Coupling consists of high-strength aluminum or steel. The wear-resistant TPU elastomer makes the claw coupling particularly resilient. The coupling has a vibration-damping effect thanks to its elastomer ring, but is free of play. The freedom from play in the claw coupling is guaranteed by the compressive preload of the elastomer ring. Two precisely manufactured hubs with clamping cones and concave claws ensure high concentricity.

Slip clutch to protect people and machines

07.02.2023/XNUMX/XNUMX | Collisions in the drive train can be triggered by operating errors or malfunctions. It is all the more important that these suddenly very high torques are decoupled from the components. Work for torque limitation slipping clutches with friction linings from Orbit Drive Technology.

07.02.2023/XNUMX/XNUMX | Collisions in the drive train can be triggered by operating errors or malfunctions. It is all the more important that these suddenly very high torques are decoupled from the components. Work for torque limitation slipping clutches with friction linings from Orbit Drive Technology.

Claw coupling for ball screw + trapezoidal thread spindle

November 20.11.2019, XNUMX | The connection of Ball Screw or Acme screw The drive journal of an engine or gearbox is usually not made rigid, but via a flexible one Clutch. This can compensate for misalignments or misalignments and minimize vibrations and shocks in the drive train. Dr. Tretter now offers compact Couplings.

November 20.11.2019, XNUMX | The connection of Ball Screw or Acme screw The drive journal of an engine or gearbox is usually not made rigid, but via a flexible one Clutch. This can compensate for misalignments or misalignments and minimize vibrations and shocks in the drive train. Dr. Tretter now offers compact Couplings.

The shaft coupling consists of two coupling halves with identical hubs with concave claws and an elastomer gear ring in between, which enables an elastic connection. These components serve as a connecting element between the drive and the ball screw and enable simple and precisely fitting assembly.

To do this, the hubs are clamped using screws. The respective inner diameter can be freely selected depending on the size. Because the aluminum is anodized, they are extremely low-corrosion.

On request, the user can also get the new shaft couplings with soft sprockets, in sizes 55 to 80 mm and with feather key. The program of Dr. Tretter also includes other types such as slats- or bellows couplings.

Elastomer coupling with new hubs and spacers

09.08.2019 | Couplingsthat the torques from the drive unit for example on the guide of a Gripper transmitted, must work with high precision and at the same time withstand the high loads. With the elastomer coupling from Mayr Antriebstechnik the required movements can be carried out precisely.

09.08.2019 | Couplingsthat the torques from the drive unit for example on the guide of a Gripper transmitted, must work with high precision and at the same time withstand the high loads. With the elastomer coupling from Mayr Antriebstechnik the required movements can be carried out precisely.

Elastic clutch with more torque and longer life

Sep 07.09.2017, XNUMX | With conventional elastomer claw couplings with a symmetrical tooth shape, the torque to be transmitted leads to a very high load on the tooth tips of the sprockets. This causes a lot of wear and requires large dimensions. The special tooth and claw geometry of the new Compensating coupling DXA by Madler ensures an even distribution of forces in the tooth, thereby increasing the permissible torque and reducing wear.

Sep 07.09.2017, XNUMX | With conventional elastomer claw couplings with a symmetrical tooth shape, the torque to be transmitted leads to a very high load on the tooth tips of the sprockets. This causes a lot of wear and requires large dimensions. The special tooth and claw geometry of the new Compensating coupling DXA by Madler ensures an even distribution of forces in the tooth, thereby increasing the permissible torque and reducing wear.

Also avoid this special tooth shape the displacement of the ring gear teeth under load towards the axis of rotation, which leads to high friction in conventional claw clutches. In addition, the finely machined surfaces offer a very smooth contact surface with the sprockets, which further increases the service life of the sprockets compared to unmachined cast surfaces.

The DXA coupling is available in 12 sizes with a diameter of 55 to 220 mm, for shaft diameters up to 100 mm and a maximum torque of up to 11.000 Nm. Finished bores, keyways and locking threads can be implemented at short notice.

Flexible jaw coupling for corrosion atmospheres

16.08.2015 | KTR coupling technology has expanded the family of “Rotex” couplings to include a further variant for use in areas at risk of corrosion: The new Rotex offers a high-quality KTL coating and achieves the corrosivity category C4-long according to DIN EN ISO 12944. The hub material is steel as standard. The coating was carried out using cathodic dip painting (KTL), also called cataphoresis.

16.08.2015 | KTR coupling technology has expanded the family of “Rotex” couplings to include a further variant for use in areas at risk of corrosion: The new Rotex offers a high-quality KTL coating and achieves the corrosivity category C4-long according to DIN EN ISO 12944. The hub material is steel as standard. The coating was carried out using cathodic dip painting (KTL), also called cataphoresis.

The result is one uniform layer thickness with very good surface quality and high temperature resistance. The environmentally friendly process offers very good corrosion properties and ensures a high fit of the hubs.

To determine the corrosion protection class, the drive specialist has one on the coated coupling components Salt spray test carried out over a period of 1000 hours. Accordingly, the new coupling variant can be assigned to the corrosivity category C4-long according to DIN EN ISO 12944.

It is ideal for use in highly atmospheric environmental conditions such as industrial atmospheres, production facilities with chemical pollution or coastal areas with moderate salt water pollution.

The multi-plate clutch and its industrial applications

The multi-plate clutch and its industrial applications

The Rotex with KTL coating Available from stock in sizes 19 to 125 and with pre-drilled hubs as standard. The elastic claw coupling is axially pluggable and maintenance-free. It offers good dynamic properties, very good vibration damping and low inertia with high torque transmission. The precise machining has a positive effect on the running properties of the clutch and significantly increases the expected service life.

The coupling with KTL coating is delivered from the factory with the high-temperature resistant T-PUR sprocket material. This is available in three degrees of hardness.

Torsionally rigid elastomer claw couplings for high speeds

12.02.2015 | Tsubaki is expanding its range of elastomer couplings (Jaw-Flex coupling) to include a taper-lock variant in line with these requirements. This expands the range of applications to 2,5 times higher shaft revolutions while maintaining the transmission performance of the previous clamping elastomer couplings.

12.02.2015 | Tsubaki is expanding its range of elastomer couplings (Jaw-Flex coupling) to include a taper-lock variant in line with these requirements. This expands the range of applications to 2,5 times higher shaft revolutions while maintaining the transmission performance of the previous clamping elastomer couplings.

FAQ

What does a claw clutch do?

A claw coupling connects two shafts in a torsionally elastic manner, firmly and without slipping, and thus transmits torque. They interlock mechanically and allow direct and slip-free power transmission. The claw clutch is form-fitting and serves for power transmission without play and torsional vibrations.

Where are claw couplings used?

Jaw clutches are typically used in applications where a rigid connection and precise alignment is required, such as in machine tools, conveyor systems, printing presses and general industrial drives.

Source: This article is based on information from the following companies: Dr. Tretter, KTR Systems, Mädler, Mayr Antriebstechnik, Orbit Antriebstechnik, R+W, Tsubaki.

You might also be interested in...

Metal bellows coupling | Innovations, applications, special features

Multi-plate clutch | Design, selection and innovations

Compensating coupling | For axial, radial and angular offset

Slip clutch | Safety through disconnection in the event of overload

High-performance brake wind turbine with monitoring